Toyota Corolla Cross: Repair

REPAIR

PROCEDURE

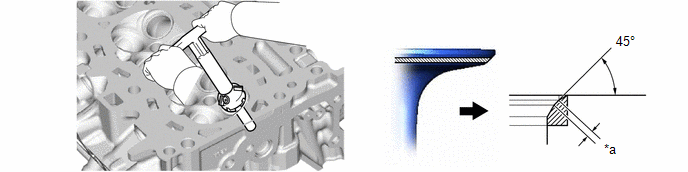

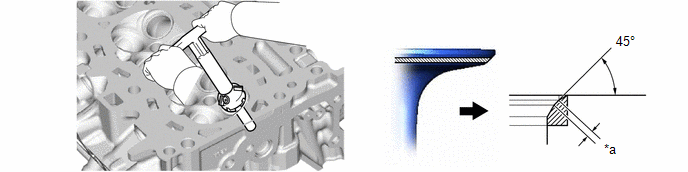

1. REPAIR EXHAUST VALVE SEAT

NOTICE:

- While repairing the exhaust valve seat, make sure to constantly check the valve seat width and valve seating position.

- Release the cutter gradually to make the exhaust valve seat smooth.

(a) Using 45° cutters, correct the exhaust valve seat so that the exhaust valve contacts the entire circumference of the exhaust valve seat. The contact should be in the center of the exhaust valve seat, and the exhaust valve seat width should be as specified around the entire circumference of the exhaust valve seat.

Standard Width:

1.3 to 1.7 mm (0.0512 to 0.0669 in.)

(b) Hand lap the exhaust valve and exhaust valve seat with an abrasive compound.

(c) Check the exhaust valve seating position.

READ NEXT:

REMOVAL CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during cy

INSTALLATION CAUTION / NOTICE / HINT

NOTICE: This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click he

SEE MORE:

UTILITY

SPEAKER CIRCUIT ENERGIZATION INSPECTION (for 9 Speakers)

HINT:

This function checks for an open in each speaker circuit.

(a) Speaker circuit energization inspection

(1) In accordance with the display of the GTS, perform a speaker

circuit energization inspection.

Body Electrical >

INSPECTION PROCEDURE 1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION: Perform the inspection in a well-ventilated area. Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E. (b) Check the fuel sender gauge assembly voltage.

(1) Apply 5 V b