Toyota Corolla Cross: Terminals Of Ecu

TERMINALS OF ECU

CHECK MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) AND POWER DISTRIBUTION BOX ASSEMBLY

.png)

(a) Remove the main body ECU (multiplex network body ECU) from the power distribution box assembly.

Click here .gif)

(b) Connect the power distribution box assembly connectors.

(c) Measure the voltage and resistance according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

MB-13 (GND1) - Body ground |

Ground | Always |

Below 1 Ω |

|

MB-14 (GND2) - Body ground |

Ground | Always |

Below 1 Ω |

|

MB-26 (BECU) - Body ground |

Auxiliary battery power supply |

Ignition switch off | 11 to 14 V |

|

MB-27 (IGR) - Body ground |

Ignition power supply |

Ignition switch off | Below 1 V |

|

Ignition switch ON | 11 to 14 V |

(d) Install the main body ECU (multiplex network body ECU).

Click here

.gif)

(e) Connect the power distribution box assembly and main body ECU (multiplex network body ECU) connectors.

(f) Measure the voltage and check for pulses according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

8E-5 - Body ground |

CXPI communication line |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

I85-26 (HEAD) - Body ground |

Light control switch in HEAD position signal input |

Light control switch not in HEAD position |

11 to 14 V |

| Light control switch in HEAD position |

Below 1 V | ||

|

8K-1 - Body ground |

IG power supply | Ignition switch off |

Below 1 V |

| Ignition switch ON |

11 to 14 V | ||

|

8E-10 - Body ground |

Headlight assembly LH power supply |

Ignition switch off | 11 to 14 V |

|

Ignition switch ON | Below 1 V | ||

|

8E-6 - Body ground |

Headlight assembly RH power supply |

Ignition switch off | 11 to 14 V |

|

Ignition switch ON | Below 1 V | ||

|

I85-8 (CLTB) - I85-21(CLTE) |

Automatic light control sensor power supply output |

Ignition switch off | Below 1 V |

|

Ignition switch ON | 11 to 14 V | ||

|

I85-14 (AHBI) - Body ground |

Auto high beam switch signal input |

Auto high beam switch on |

Below 1 V |

| Auto high beam switch off |

11 to 14 V | ||

|

I85-15 (AHID) - Body ground |

Auto high beam switch indicator drive output |

Ignition switch ON, auto high beam switch off |

11 to 14 V |

| Ignition switch ON, auto high beam switch on |

Below 1 V | ||

|

I85-20 (CLTS) - Body ground |

Automatic light control sensor signal input |

Ignition switch ON | Pulse generation (See waveform 1) |

|

8C-9 - Body ground | Front door courtesy light switch assembly RH input |

Front door RH open | 4.7 to 5.3 V |

|

Front door RH closed |

Below 1 V |

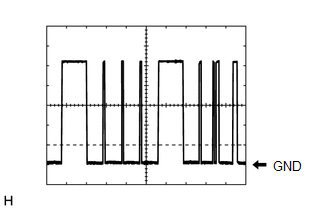

(1) Waveform 1

|

Item | Content |

|---|---|

|

Tester Connection | I85-20 (CLTS) - Body ground |

|

Tool setting | 2 V/DIV., 10 ms./DIV. |

|

Condition | Ignition switch ON |

HINT:

The communication waveform changes according to the surrounding brightness.

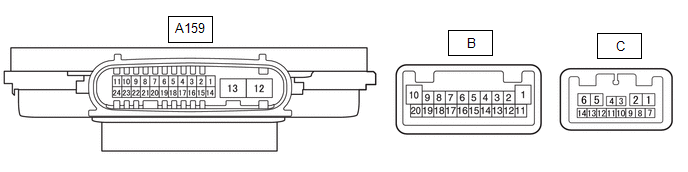

CHECK HEADLIGHT ECU SUB-ASSEMBLY LH

(a) Disconnect the A159 headlight ECU sub-assembly LH connector.

(b) Measure the voltage and resistance on the wire harness side connector according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A159-6 (IGR) - Body ground |

IG power supply | Ignition switch off |

Below 1 V |

| Ignition switch ON |

11 to 14 V | ||

|

A159-12 (GND) - Body ground |

Ground | Always |

Below 1 Ω |

|

A159-13 (ECUB) - Body ground |

Auxiliary battery power supply |

| Below 1 V |

| 9.5 to 14 V |

(c) Connect the A159 headlight ECU sub-assembly LH connector.

HINT:

- Since the A159 headlight ECU sub-assembly LH connector is a waterproof type connector, the voltage and pulses cannot be checked directly. The values listed are for reference only.

- Since the B and C headlight ECU sub-assembly LH connectors are connected inside the headlight unit assembly, the voltage and pulses cannot be checked directly. The values listed are for reference only.

(d) Measure the voltage and check of pulses according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A159-3 (HEDL) - Body ground |

Low beam headlights drive output |

Light control switch not in head position |

11 to 14 V |

| Light control switch in head position |

Below 1 V | ||

|

A159-16 (SBR) - A159-15 (SGR) |

Rear height control sensor sub-assembly LH power supply |

Ignition switch off | Below 1 V |

|

Ignition switch ON | 4.75 to 5.25 V | ||

|

A159-17 (SHRL) - A159-15 (SGR) |

Rear height control sensor sub-assembly LH signal input |

Ignition switch ON, vehicle unloaded, vehicle stopped |

Approximately 2.5 V (value decreases as the front of the vehicle is raised) |

|

A159-20 (LINL) - Body ground |

LIN communication line (to headlight ECU sub-assembly RH) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A159-21 (LCL) - Body ground |

CAN communication line (Local) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A159-22 (LCH) - Body ground |

CAN communication line (Local) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A159-23 (CANL) - Body ground |

CAN communication line (Global) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A159-24 (CANH) - Body ground |

CAN communication line (Global) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

B-2 (LED1+) - B-12 (LED1-) |

Low beam headlights drive output |

Low beam headlights off |

Below 1 V |

| Low beam headlights on |

10.7 to 15.3 V | ||

|

B-9 (ACTB) - B-18 (ACTG) |

Headlight leveling motor power source |

Ignition switch off | Below 1 V |

|

Ignition switch ON | 11 to 14 V | ||

|

B-15 (LED3+) - B-16 (LED3-) |

Clearance lights drive output |

Clearance lights off |

Below 1 V |

| Clearance lights on |

7.6 to 11.0 V | ||

|

Daytime running lights drive output |

Daytime running lights off |

Below 1 V | |

| Daytime running lights on |

15.2 to 22.0 V | ||

|

C-1 (PSWH2+) - C-2 (PSWH2-) |

Light control LED ECU power source |

| Below 1 V |

| 9.5 to 14 V | ||

|

C-12 (LIN1_1) - Body ground |

LIN communication line (to Headlight leveling motor) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

C-13 (LIN1_2) - Body ground |

LIN communication line (to Light control LED ECU) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation |

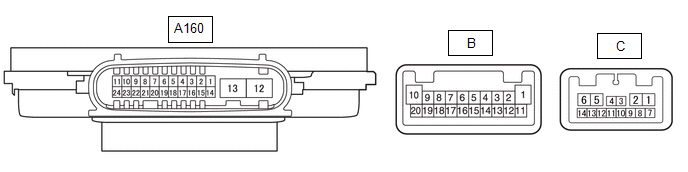

CHECK HEADLIGHT ECU SUB-ASSEMBLY RH

(a) Disconnect the A160 headlight ECU sub-assembly RH connector.

(b) Measure the voltage and resistance on the wire harness side connector according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A160-6 (IGR) - Body ground |

IG power supply | Ignition switch off |

Below 1 V |

| Ignition switch ON |

11 to 14 V | ||

|

A160-12 (GND) - Body ground |

Ground | Always |

Below 1 Ω |

|

A160-13 (ECUB) - Body ground |

Auxiliary battery power supply |

| Below 1 V |

| 9.5 to 14 V |

(c) Connect the A160 headlight ECU sub-assembly RH connector.

HINT:

- Since the A160 headlight ECU sub-assembly RH connector is a waterproof type connector, the voltage and pulses cannot be checked directly. The values listed are for reference only.

- Since the B and C headlight ECU sub-assembly RH connectors are connected inside the headlight unit assembly, the voltage and pulses cannot be checked directly. The values listed are for reference only.

(d) Measure the voltage and check of pulses according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A160-20 (LINL) - Body ground |

LIN communication line (to headlight ECU sub-assembly LH) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A160-23 (CANL) - Body ground |

CAN communication line (Global) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

A160-24 (CANH) - Body ground |

CAN communication line (Global) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

B-2 (LED1+) - B-12 (LED1-) |

Low beam headlights drive output |

Low beam headlights off |

Below 1 V |

| Low beam headlights on |

10.7 to 15.3 V | ||

|

B-9 (ACTB) - B-18 (ACTG) |

Headlight leveling motor power source |

Ignition switch off | Below 1 V |

|

Ignition switch ON | 11 to 14 V | ||

|

B-15 (LED3+) - B-16 (LED3-) |

Clearance lights drive output |

Clearance lights off |

Below 1 V |

| Clearance lights on |

7.6 to 11.0 V | ||

|

Daytime running lights drive output |

Daytime running lights off |

Below 1 V | |

| Daytime running lights on |

15.2 to 22.0 V | ||

|

C-1 (PSWH2+) - C-2 (PSWH2-) |

Light control LED ECU power source |

| Below 1 V |

| 9.5 to 14 V | ||

|

C-12 (LIN1_1) - Body ground |

LIN communication line (to Headlight leveling motor) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation | ||

|

C-13 (LIN1_2) - Body ground |

LIN communication line (to Light control LED ECU) |

Ignition switch off | Below 1 V |

|

Ignition switch ON | Pulse generation |

CHECK COMBINATION METER ASSEMBLY

Click here

.gif)

CHECK FORWARD RECOGNITION CAMERA

Click here .gif)

CHECK STEERING SENSOR

for HEV Model: Click here .gif)

for Gasoline Model: Click here

.gif)

SEMICONDUCTOR POWER INTEGRATION ECU

Click here .gif)