Toyota Corolla Cross: Removal

REMOVAL

CAUTION / NOTICE / HINT

COMPONENTS (REMOVAL)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

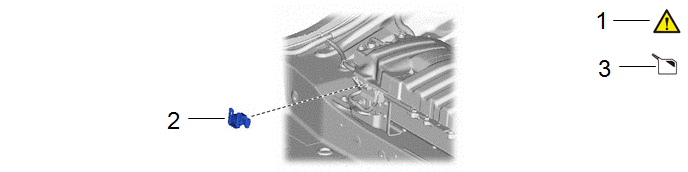

1 | PRECAUTION |

- |

|

- | - |

|

2 | SERVICE PLUG GRIP |

G3834 | - |

- | - |

|

3 | COOLANT (for Inverter) |

- | - |

|

- |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

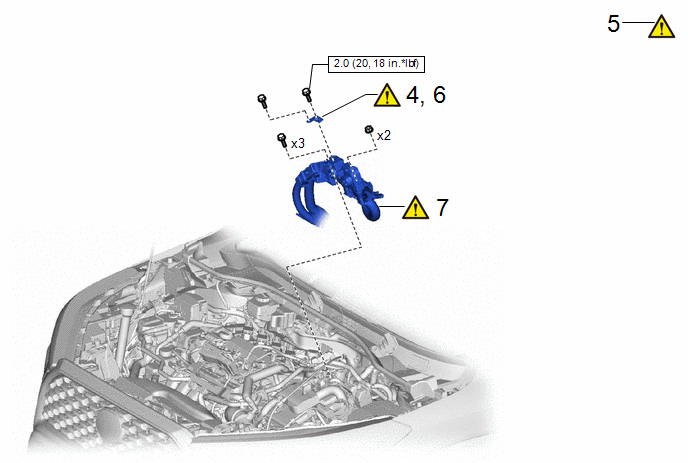

4 | REMOVE CONNECTOR COVER ASSEMBLY |

- | - |

- | - |

|

5 | TERMINAL VOLTAGE |

- |

|

- | - |

|

6 | TEMPORARILY INSTALL CONNECTOR COVER ASSEMBLY |

- |

|

- | - |

|

7 | FLOOR UNDER WIRE |

821H1 |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

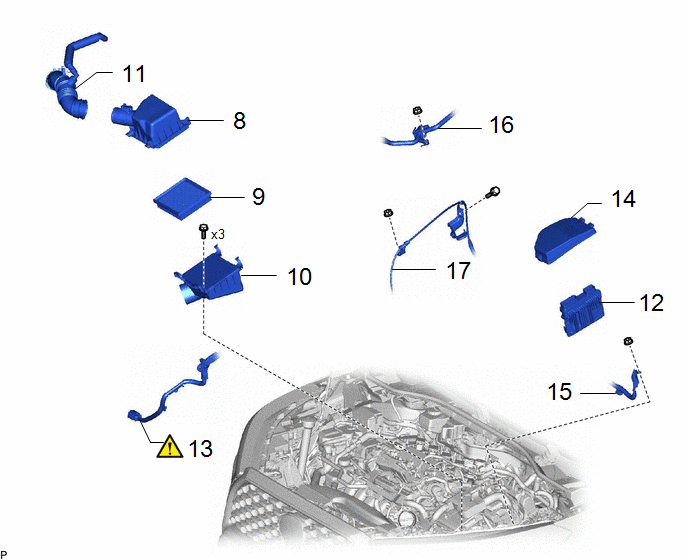

8 | AIR CLEANER CAP SUB-ASSEMBLY |

17705 | - |

- | - |

|

9 | AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY |

17801 | - |

- | - |

|

10 | AIR CLEANER CASE SUB-ASSEMBLY |

17701 | - |

- | - |

|

11 | NO. 1 AIR CLEANER HOSE |

17881 | - |

- | - |

|

12 | ECM |

89661 | - |

- | - |

|

13 | HV AIR CONDITIONING WIRE |

821H2 |

|

- | - |

|

14 | NO.2 RELAY BLOCK COVER |

82662B | - |

- | - |

|

15 | NO.3 ENGINE WIRE |

82123 | - |

- | - |

|

16 | VACUUM SWITCHING VALVE ASSEMBLY |

17650 | - |

- | - |

|

17 | TRANSMISSION CONTROL CABLE ASSEMBLY |

33820B | - |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

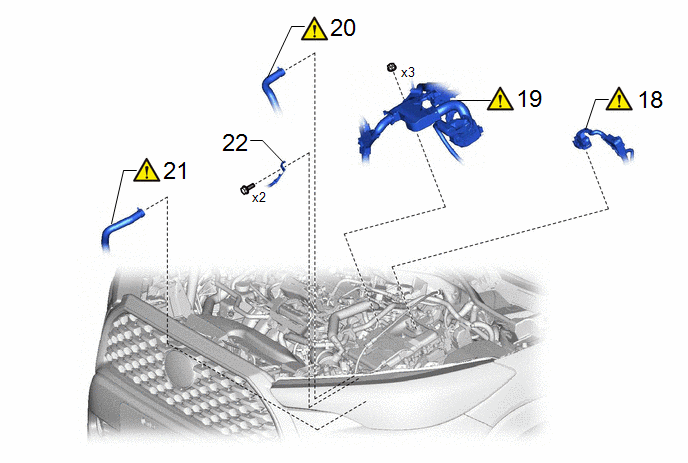

18 | ENGINE ROOM MAIN WIRE |

82111 |

|

- | - |

|

19 | ENGINE WIRE |

82121 |

|

- | - |

|

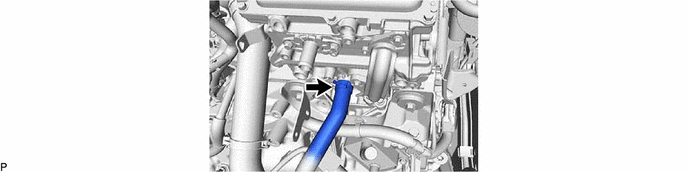

20 | OUTLET NO. 1 INVERTER COOLING HOSE |

G922C |

|

- | - |

|

21 | INLET NO. 1 INVERTER COOLING HOSE |

G922AA |

|

- | - |

|

22 | NO. 7 ENGINE, WIRE |

82127D |

|

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

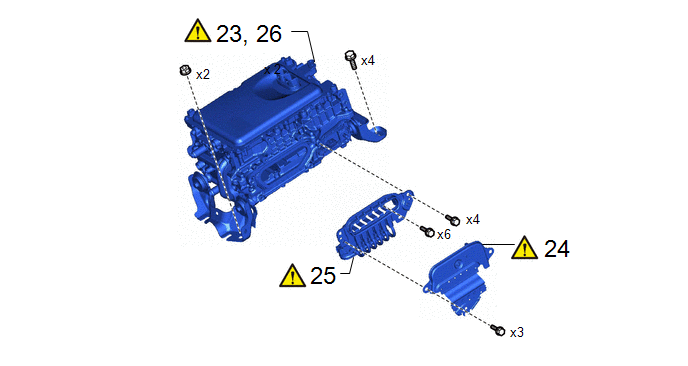

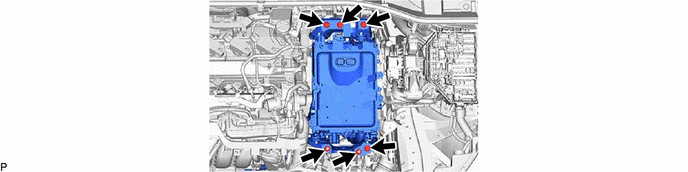

23 | SEPARATE INVERTER WITH CONVERTER ASSEMBLY |

G92A0 |

|

- | - |

|

24 | UPPER INVERTER COVER |

G9221 |

|

- | - |

|

25 | MOTOR CABLE |

G1148 |

|

- | - |

|

26 | REMOVE INVERTER WITH CONVERTER ASSEMBLY |

G92A0 |

|

- | - |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during hybrid motor control inverter assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedures |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Replacement of hybrid motor control inverter assembly |

Resolver learning |

|

|

CAUTION:

- Orange wire harnesses and connectors indicate high-voltage circuits. To prevent electric shock, always follow the procedure described in the repair manual.

.png)

Click here

.gif)

- To prevent electric shock, wear insulated gloves when working on wire harnesses and components of the high voltage system.

.png)

HINT:

When the cable is disconnected/reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

- Learning completes when vehicle is driven.

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Front Camera System

Drive the vehicle straight ahead at 15 km/h (10 mph) or more for 1 second or more.

.gif)

- Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

.gif)

Power back door system

Fully close the back door by hand.

HINT:

Initialization is not necessary if the above procedures are performed while the back door is closed.

.gif)

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. PRECAUTION

.png) |

NOTICE: After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Click here |

2. REMOVE SERVICE PLUG GRIP

Click here

.gif)

3. DRAIN COOLANT (for Inverter)

Click here .gif)

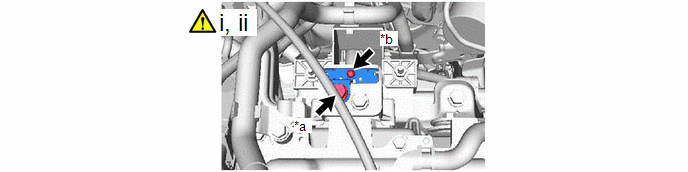

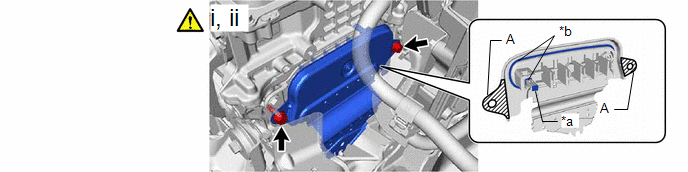

4. REMOVE CONNECTOR COVER ASSEMBLY

.png) |

CAUTION: Wear insulated gloves. |

|

*a | Bolt (A) |

*b | Bolt (B) |

(1) Remove the bolt (A).

(2) Using a T20 "TORX" socket wrench, remove the bolt (B) and connector cover assembly from the hybrid motor control inverter assembly.

NOTICE:

- Do not touch the connector cover assembly waterproof seal.

- Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly.

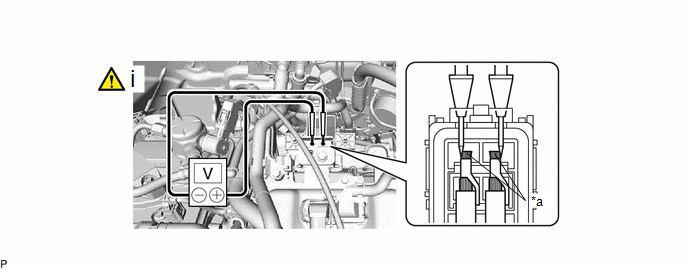

5. CHECK TERMINAL VOLTAGE

.png) |

CAUTION: Wear insulated gloves. NOTICE: Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly. |

|

*a | Terminal |

- | - |

(1) Measure the voltage between the terminals of the high voltage DC line.

Specified Voltage:

0 V

HINT:

- Set the tester to the DC 750 V range or higher to measure the voltage.

- Perform the measurement while holding the tips of the tester probes against the terminals as shown in the illustration.

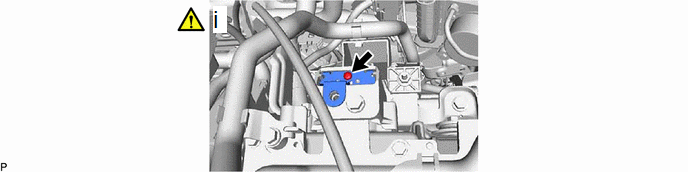

6. TEMPORARILY INSTALL CONNECTOR COVER ASSEMBLY

.png) |

CAUTION: Wear insulated gloves. NOTICE: Do not touch the waterproof seal of the connector cover assembly. |

(1) Using a T20 "TORX" socket wrench, temporarily install the connector cover assembly to the hybrid motor control inverter assembly with the bolt.

Torque:

2.0 N·m {20 kgf·cm, 18 in·lbf}

7. DISCONNECT FLOOR UNDER WIRE

.png) |

CAUTION: Wear insulated gloves. NOTICE: Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly. NOTICE:

|

|

*a | Waterproof Seal |

- | - |

(1) Remove the 2 bolts, 2 nuts and disconnect the HV floor under wire from the hybrid motor control inverter assembly.

(2) Disengage the 2 clamps.

8. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

9. REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

Click here .gif)

10. REMOVE AIR CLEANER CASE SUB-ASSEMBLY

11. REMOVE NO. 1 AIR CLEANER HOSE

12. REMOVE ECM

.png) |

Click here |

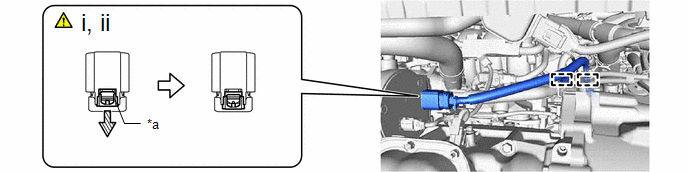

13. DISCONNECT HV AIR CONDITIONING WIRE

.png) |

CAUTION: Wear insulated gloves. NOTICE:

|

|

*a | Green-colored Lock |

- | - |

|

Slide | - |

- |

(1) Disengage the 2 clamps.

(2) Slide the green-colored lock of the connector as shown in the illustration to release it and disconnect the HV air conditioning wire.

14. REMOVE NO.2 RELAY BLOCK COVER

15. DISCONNECT NO.3 ENGINE WIRE

16. REMOVE VACUUM SWITCHING VALVE ASSEMBLY

17. DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

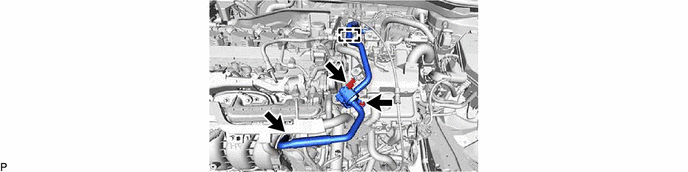

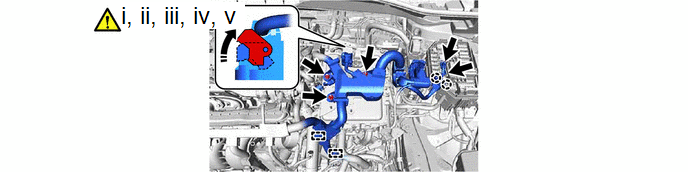

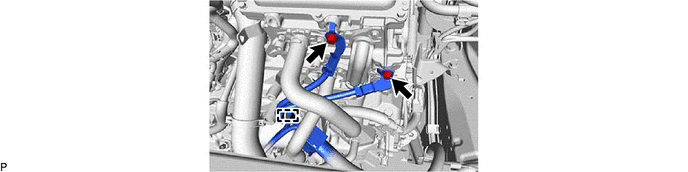

18. DISCONNECT ENGINE ROOM MAIN WIRE

.png) |

CAUTION: Wear insulated gloves. NOTICE: Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly. |

(1) Disengage the clamp and disconnect the connector.

(2) Move the lock lever while pushing the lock on the connector, and disconnect the hybrid motor control inverter assembly connector.

NOTICE:

- Do not damage the terminals, connector housing or hybrid motor control inverter assembly during disconnection.

- Cover the hole where the cable was connected with tape (non-residue type) or equivalent to prevent entry of foreign matter.

- Insulate the disconnected terminals with insulating tape.

- Do not touch the waterproof seal or terminals of the connector.

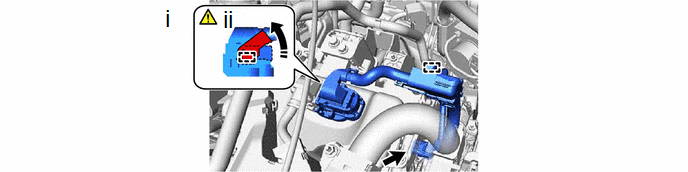

19. DISCONNECT ENGINE WIRE

.png) |

CAUTION: Be sure to wear insulated gloves. NOTICE: Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly. |

(1) Move the lock lever while pushing the lock on the connector, and disconnect the hybrid motor control inverter assembly connector.

NOTICE:

- Do not damage the terminals, connector housing or hybrid motor control inverter assembly during disconnection.

- Cover the hole where the cable was connected with tape (non-residue type) or equivalent to prevent entry of foreign matter.

- Insulate the disconnected terminals with insulating tape.

- Do not touch the waterproof seal or terminals of the connector.

(2) Disconnect the 2 connectors.

(3) Disengage the 2 claws.

(4) Remove the 3 nuts.

(5) Disengage the 2 clamps.

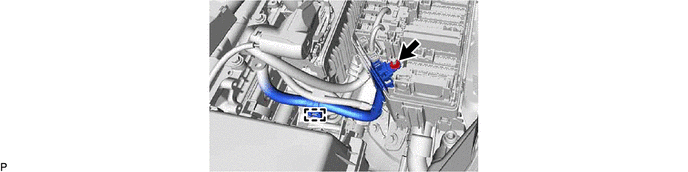

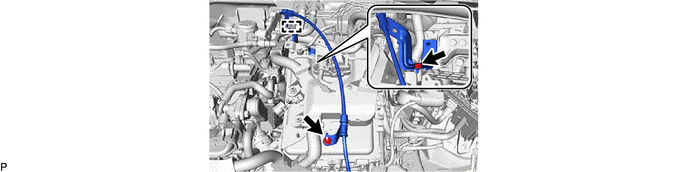

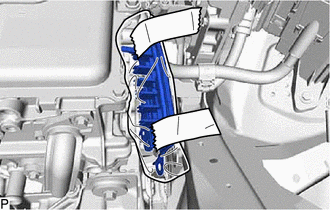

20. DISCONNECT OUTLET NO. 1 INVERTER COOLING HOSE

.png) |

NOTICE: Put pieces of cloth into the pipe and disconnected hose or cover the pipe and hose with plastic bags to prevent entry of foreign matter. |

21. DISCONNECT INLET NO. 1 INVERTER COOLING HOSE

.png) |

NOTICE: Put pieces of cloth into the pipe and disconnected hose or cover the pipe and hose with plastic bags to prevent entry of foreign matter. |

22. DISCONNECT NO. 7 ENGINE, WIRE

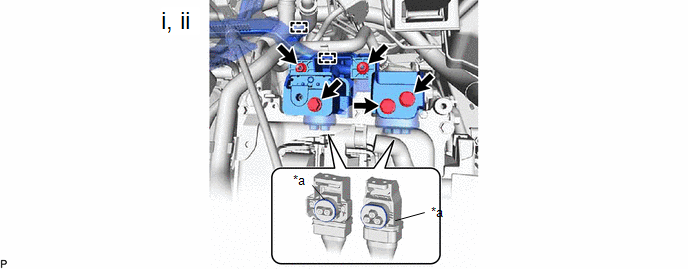

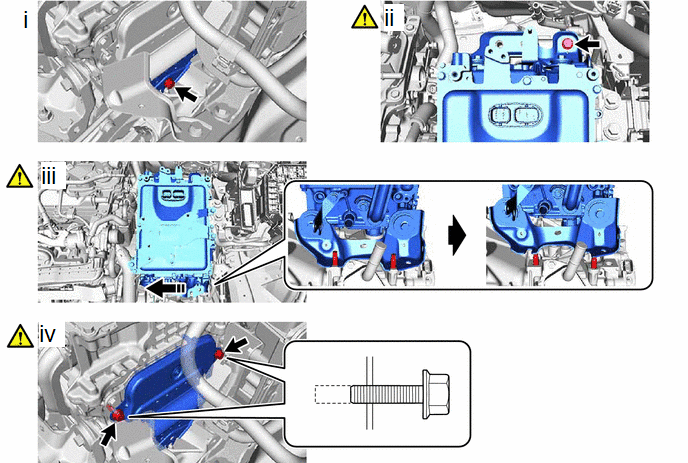

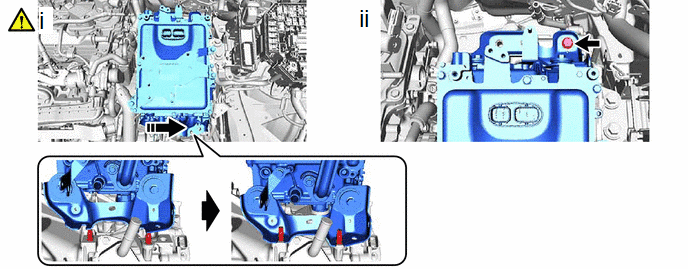

23. SEPARATE INVERTER WITH CONVERTER ASSEMBLY

.png) |

CAUTION: Be sure to wear insulated gloves. NOTICE: To prevent damage due to static electricity, do not touch the terminals of the disconnected connectors. |

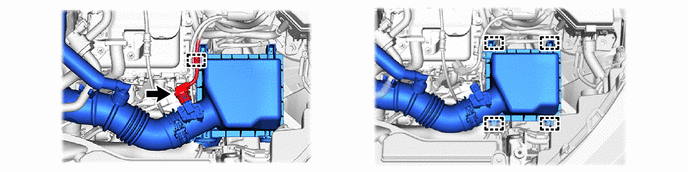

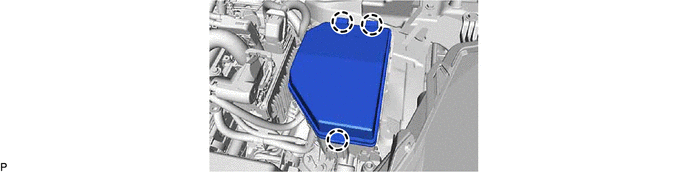

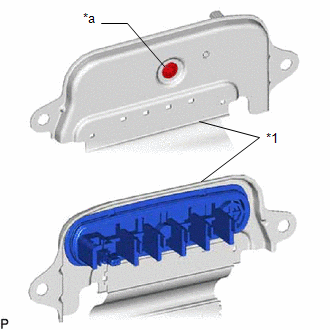

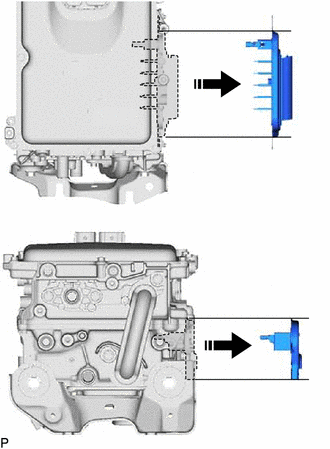

24. REMOVE UPPER INVERTER COVER

.png) |

CAUTION: Wear insulated gloves. |

(1) Remove the bolt and inverter cover from the hybrid vehicle transaxle assembly.

(2) To prevent the inverter with converter assembly from falling, temporarily install the bolt in the location shown in the illustration.

(3) Shift the position of the inverter with converter assembly and temporarily set it on top of the stud bolts as shown in the illustration.

NOTICE:

When lifting, make sure not to apply force to the motor cable.

(4) Loosen the 2 bolts, leaving 2 to 3 threads at the tip of the bolt still engaged.

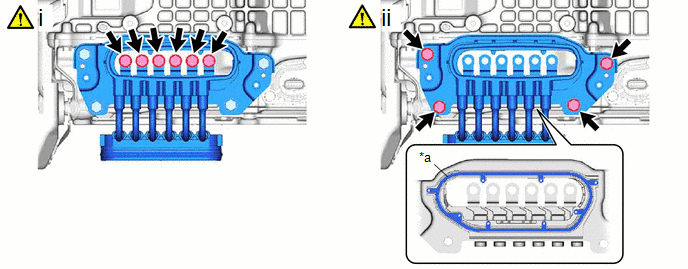

|

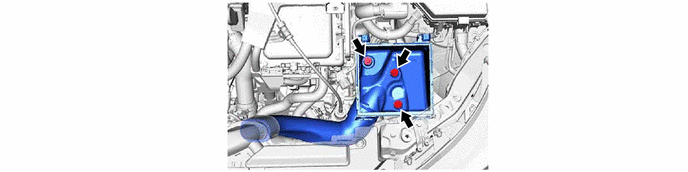

*a | Interlock |

*b | Waterproof Seal |

(1) Using the 2 bolts as guides, remove the upper inverter cover from the inverter with converter assembly.

NOTICE:

- Make sure to pull the upper inverter cover straight out, as a connector is connected to the inside of the upper inverter cover.

- Do not touch the waterproof seal of the upper inverter cover.

- Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly.

- When removing the upper inverter cover, do not pull the areas (A) as they may deform.

- Make sure that the interlock is installed to the upper inverter cover.

- Do not remove or excessively tighten the screw of the upper inverter cover.

*1

Inverter Cover

*a

Screw

- Although the inverter cover may feel loose, this is not due to a malfunction.

- Hold the upper inverter cover horizontal while removing it.

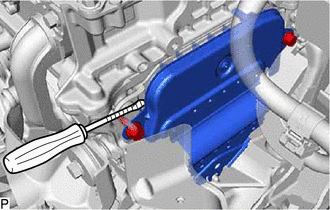

HINT:

If necessary, use a screwdriver with its tip wrapped with protective tape as shown in the illustration to remove the upper inverter cover.

(2) Remove the 2 bolts.

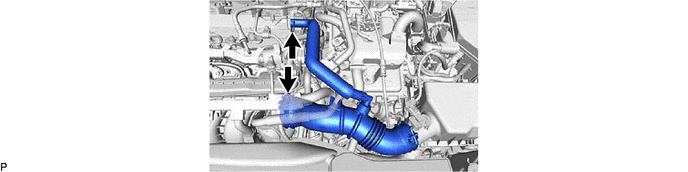

(1) Shift the position of the inverter with converter assembly and temporarily set it on the hybrid vehicle transaxle assembly as shown in the illustration.

NOTICE:

When lifting, make sure not to apply force to the motor cable.

(2) Remove the bolt.

25. DISCONNECT MOTOR CABLE

.png) |

CAUTION: Wear insulated gloves. |

|

*a | Waterproof Seal |

- | - |

(1) Using an insulated tool, remove the 6 bolts.

NOTICE:

- Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly.

- Do not touch the waterproof seal or terminals of the connector.

(2) Remove the 4 bolts and disconnect the motor cable from the hybrid motor control inverter assembly.

NOTICE:

- Do not allow any foreign matter or water to enter the hybrid motor control inverter assembly.

- Do not touch the waterproof seal or terminals of the connector.

- Do not damage the terminals, connector housing or hybrid motor control inverter assembly during disconnection.

- Insulate the disconnected terminals with insulating tape.

- Cover the hole where the cable was connected with tape (non-residue type) or equivalent to prevent entry of foreign matter.

- To prevent the wire harness from being caught, make sure to bundle the wire harness using insulating tape or equivalent.

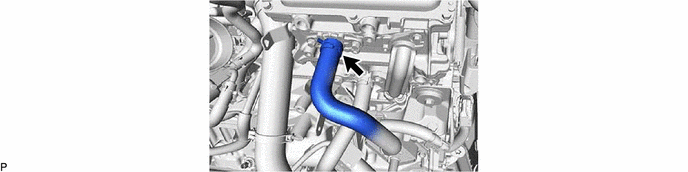

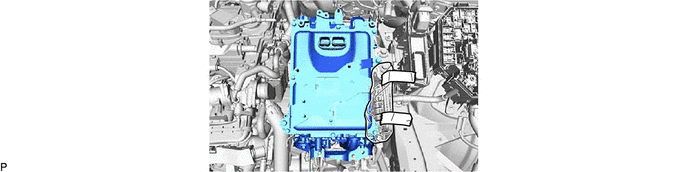

26. REMOVE INVERTER WITH CONVERTER ASSEMBLY

.png) |

CAUTION: Be sure to wear insulated gloves. NOTICE:

|

(1) Even after the coolant is drained, coolant remains in the inverter due to its internal structure. Therefore, seal or cover the pipes when removing the hybrid motor control inverter assembly so that coolant does not spill out.