Toyota Corolla Cross: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

2 | FUEL HOSE BRACKET |

23881B | - |

- | - |

|

3 | HV AIR CONDITIONING WIRE |

821H2 |

|

- | - |

|

4 | NO. 3 ENGINE WIRE |

82123 |

|

- | - |

|

5 | NO. 2 INVERTER BRACKET |

G9215 |

|

- | - |

|

6 | NO. 1 INVERTER BRACKET |

G9214 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

PROCEDURE

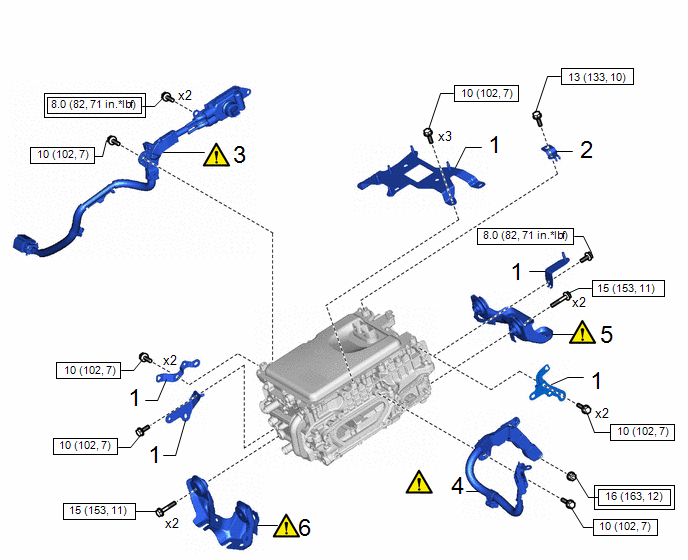

1. INSTALL WIRE HARNESS CLAMP BRACKET

Torque:

Bolt A :

10 N·m {102 kgf·cm, 7 ft·lbf}

Bolt B :

8.0 N·m {82 kgf·cm, 71 in·lbf}

2. INSTALL FUEL HOSE BRACKET

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

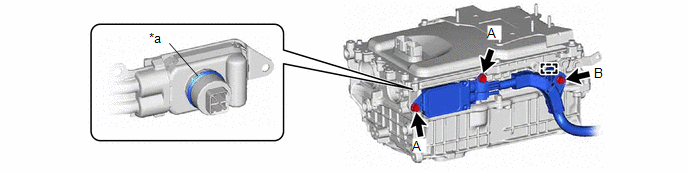

3. INSTALL HV AIR CONDITIONING WIRE

.png) |

CAUTION: Be sure to wear insulated gloves. NOTICE:

|

|

*a | Waterproof Seal |

- | - |

Torque:

Bolt A :

8.0 N·m {82 kgf·cm, 71 in·lbf}

Bolt B :

10 N·m {102 kgf·cm, 7 ft·lbf}

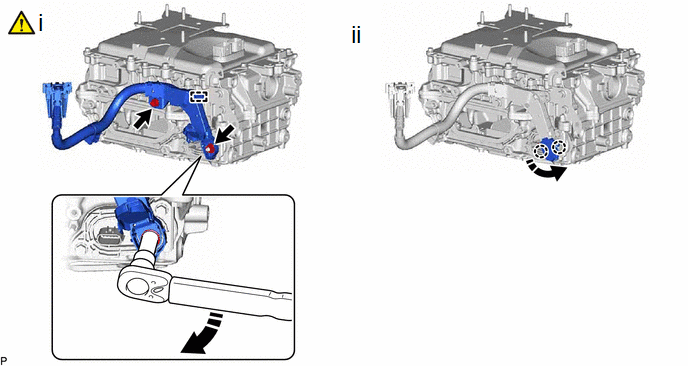

4. INSTALL NO. 3 ENGINE WIRE

.png) |

CAUTION: Be sure to wear insulated gloves. NOTICE:

|

(1) Engage the clamp and connect the engine wire to the inverter with converter assembly with bolt and nut.

Torque:

Bolt :

10 N·m {102 kgf·cm, 7 ft·lbf}

Nut :

16 N·m {163 kgf·cm, 12 ft·lbf}

NOTICE:

- Move the tool in the downward direction to tighten the nut as shown in the illustration.

- To avoid damaging the threads, be sure to perform the procedure by hand.

(2) Engage the 2 claws.

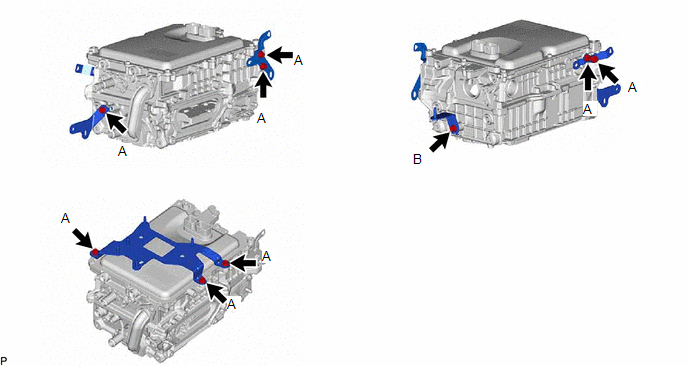

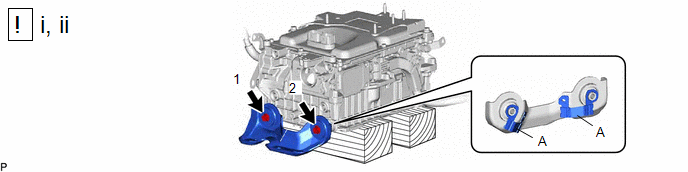

5. INSTALL NO. 2 INVERTER BRACKET

.png) |

NOTICE: Make sure to support the inverter with converter assembly at the positions shown in the illustration, otherwise it may be damaged. .png)

|

(1) Set the inverter with converter assembly on wooden blocks.

(2) Temporarily install the No. 2 inverter bracket to the inverter with converter assembly with the 2 bolts.

NOTICE:

Do not touch portion (A) of the No. 2 inverter bracket.

(3) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

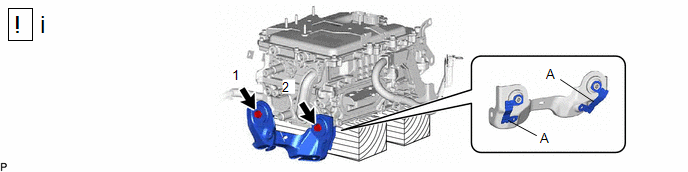

6. INSTALL NO. 1 INVERTER BRACKET

(1) Temporarily install the No. 1 inverter bracket to the inverter with converter assembly with the 2 bolts.

NOTICE:

Do not touch portion (A) of the No. 1 inverter bracket.

(2) Fully tighten the 2 bolts in the order shown in the illustration.

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

.gif)