Toyota Corolla Cross: Motor Electronics Coolant Pump "A" No Signal (P314A31)

DESCRIPTION

Refer to the description for DTC P0C7396.

Click here .gif)

The inverter water pump assembly sends the inverter water pump speed (measured value) signal to the hybrid vehicle control ECU.

|

DTC No. | Detection Item |

DTC Detection Condition |

Trouble Area | MIL |

Warning Indicate | Note |

|---|---|---|---|---|---|---|

|

P314A31 | Motor Electronics Coolant Pump "A" No Signal |

The inverter water pump speed signal is not sent to the hybrid vehicle control ECU when the ignition switch is turned to ON (READY).* (1 trip detection logic) |

| Comes on |

Master Warning: Comes on |

SAE Code: P314A |

- A malfunction (open, short to +B or short to ground) in the speed signal line from the inverter water pump assembly to the hybrid vehicle control ECU is detected.

- A malfunction in the +B line is detected.

- A malfunction in the inverter water pump assembly power source circuit is detected.

- A malfunction in hybrid vehicle control ECU power source circuit is detected.

MONITOR DESCRIPTION

The hybrid vehicle control ECU monitors the speed of the inverter water pump assembly. If the inverter water pump speed signal is not sent to the hybrid vehicle control ECU, the hybrid vehicle control ECU will illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs | P314A (INF P314A31): Inverter water pump malfunction |

|

Required sensors/components |

Inverter Water Pump Assembly |

|

Frequency of operation |

Continuous |

|

Duration | TMC's intellectual property |

|

MIL operation | Immediately |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

Hybrid vehicle control ECU |

DTC P314A (INF P314A31) is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

.gif)

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

.gif)

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the GTS on.

- Turn the ignition switch to ON (READY) and wait for 2 minutes or more. [*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Hybrid Control / Utility / All Readiness.

- Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for Cooling System.

Click here .gif)

PROCEDURE

|

1. | CLEAR DTC |

(a) Read and record the DTCs and Freeze Frame Data.

Powertrain > Hybrid Control > Trouble Codes(b) Clear the DTCs and Freeze Frame Data.

Powertrain > Hybrid Control > Clear DTCs(c) Turn the ignition switch off and wait for 2 minutes or more.

|

|

2. | PERFORM ACTIVE TEST USING GTS (ACTIVATE THE INVERTER WATER PUMP) |

NOTICE:

- Make sure that the HV coolant level is above the low line of the inverter reserve tank.

- Be sure to perform the inspection with the auxiliary battery voltage at 11 V or more.

HINT:

- When the auxiliary battery voltage is low, the inverter water pump assembly may not operate.

- When the inverter water pump assembly signal line (SWP - IWP) is open or its connection is faulty, the inverter water pump assembly is operated forcibly.

(a) Perform the "Activate the Inverter Water Pump" Active Test.

Powertrain > Hybrid Control > Active Test|

Tester Display |

|---|

|

Activate the Inverter Water Pump |

(b) Touch the inverter water pump assembly and check that it is operating (vibrating).

OK:

The inverter water pump is operating (vibrating).

HINT:

Perform the Active Test with the inverter coolant temperature between -15 and 65°C (5 to 149°F).

(c) Turn the ignition switch off.

| NG | .gif) | GO TO STEP 9 |

|

|

3. | CHECK CONNECTOR CONNECTION CONDITION (HYBRID VEHICLE CONTROL ECU CONNECTOR) |

Click here .gif)

| NG | .gif) | CONNECT SECURELY |

|

|

4. | CHECK CONNECTOR CONNECTION CONDITION (INVERTER WATER PUMP ASSEMBLY CONNECTOR) |

Click here .gif)

| NG | .gif) | CONNECT SECURELY |

|

|

5. | CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - INVERTER WATER PUMP ASSEMBLY) |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Disconnect the inverter water pump assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A192-33 (NIWP) - A184-2 (NWP) |

Ignition switch off |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A192-33 (NIWP) or A184-2 (NWP) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

HINT:

Check the condition (looseness, deterioration, etc.) of the wire to body ground for the inverter water pump assembly.

(d) Reconnect the inverter water pump assembly connector.

(e) Reconnect the hybrid vehicle control ECU connector.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. | CHECK HYBRID VEHICLE CONTROL ECU |

(a) Disconnect the inverter water pump assembly connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

|

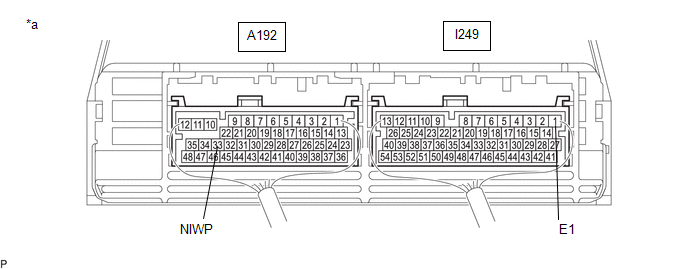

*a | Component with harness connected (Hybrid Vehicle Control ECU) |

- | - |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A192-33 (NIWP) - I249-1 (E1) |

Ignition switch ON |

11 to 14 V |

(d) Turn the ignition switch off.

(e) Reconnect the inverter water pump assembly connector.

| NG | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

|

|

7. | CLEAR DTC |

Click here

.gif)

|

|

8. | PERFORM ACTIVE TEST USING GTS (ACTIVATE THE INVERTER WATER PUMP) |

NOTICE:

Be sure to perform the inspection with the auxiliary battery voltage at 11 V or more.

HINT:

When the auxiliary battery voltage is low, the inverter water pump assembly may not operate.

(a) Perform the "Activate the Inverter Water Pump" Active Test.

Powertrain > Hybrid Control > Active Test|

Tester Display |

|---|

|

Activate the Inverter Water Pump |

(b) Connect an oscilloscope between the hybrid vehicle control ECU terminals specified in the table below, and measure the waveform.

|

*a | Component with harness connected (Hybrid Vehicle Control ECU) |

- | - |

|

Item | Content |

|---|---|

|

Terminal | A192-33 (NIWP) - I249-1 (E1) |

|

Equipment Setting |

5 V/DIV., 5 ms./DIV. |

|

Condition | Ignition switch ON, during Active Test |

OK:

The period of the wavelength is 13 msec or less.

(c) Turn the ignition switch off.

| OK | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

| NG | .gif) | GO TO STEP 15 |

|

9. | CHECK CONNECTOR CONNECTION CONDITION (INVERTER WATER PUMP ASSEMBLY CONNECTOR) |

Click here .gif)

| NG | .gif) | CONNECT SECURELY (INVERTER WATER PUMP ASSEMBLY CONNECTOR) |

|

|

10. | CHECK INSTALLATION CONDITION (INV W/PMP RELAY) |

(a) Check installation condition of the INV W/PMP relay.

OK:

INV W/PMP relay is installed correctly.

| NG | .gif) | GO TO STEP 17 |

|

|

11. | CHECK HARNESS AND CONNECTOR (IGCT-MAIN NO. 2 RELAY - INV W/PMP RELAY) |

(a) Remove the IGCT-MAIN NO. 2 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

| (c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

NOTICE: Do not apply excessive force when using the probes of the tester to perform the inspection. If excessive force is used, the terminals will be damaged. HINT:

|

|

(d) Install the IGCT-MAIN NO. 2 relay and INV W/PMP relay.

| NG | .gif) | GO TO STEP 18 |

|

|

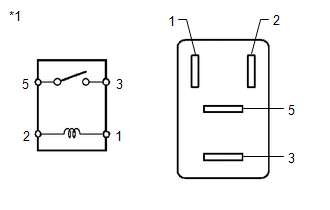

12. | INSPECT RELAY (INV W/PMP) |

(a) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Install the INV W/PMP relay.

| NG | .gif) | GO TO STEP 20 |

|

|

13. | CHECK HARNESS AND CONNECTOR (INVERTER WATER PUMP ASSEMBLY - BODY GROUND) |

|

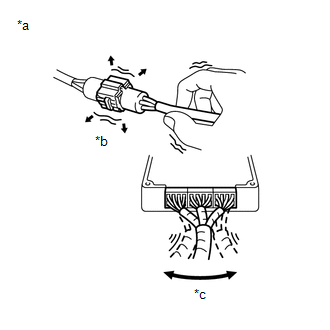

*a | Example |

|

*b | Shake Slightly |

|

*c | Vibrate Slightly |

(a) Disconnect the inverter water pump assembly connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A184-4 (+BWP) - Body ground |

Ignition switch ON |

11 to 14 V |

NOTICE:

- If the ignition switch is turned to ON with the connectors disconnected, other DTCs will be stored. Be sure to clear the DTCs after the inspection.

- Do not apply excessive force when using the probes of the tester to perform the inspection. If excessive force is used, the terminals will be damaged.

HINT:

- Connectors

Slightly shake the connector vertically and horizontally.

- Wire Harness

Slightly shake the wire harness vertically and horizontally.

The connector joint and fulcrum of the vibration are the major areas that should be checked thoroughly.

- No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly

Apply slight vibration with a finger to the No. 1 engine room relay block and No. 1 junction block assembly and check whether a malfunction occurs.

- INV W/PMP NO. 2 fuse

Apply slight vibration with a finger to the INV W/PMP NO. 2 fuse and check whether a malfunction occurs.

- INV W/PMP Relay

Apply slight vibration with a finger to the INV W/PMP relay and check whether a malfunction occurs.

(d) Turn the ignition switch off.

(e) Reconnect the inverter water pump assembly connector.

| NG | .gif) | GO TO STEP 21 |

|

|

14. | CHECK HARNESS AND CONNECTOR (INVERTER WATER PUMP ASSEMBLY - BODY GROUND) |

(a) Disconnect the inverter water pump assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A184-1 (GND) - Body ground |

Ignition switch off |

Below 1 Ω |

(c) Reconnect the inverter water pump assembly connector.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

15. | REPLACE INVERTER WATER PUMP ASSEMBLY |

Click here .gif)

|

|

16. | ADD HV COOLANT AND PERFORM AIR BLEEDING |

(a) After replacing the inverter water pump assembly, add HV coolant and perform air bleeding.

Click here .gif)

| NEXT | .gif) | END |

|

17. | INSPECT RELAY (INV W/PMP) |

(a) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Install the INV W/PMP relay.

| OK | .gif) | CONNECT SECURELY (INV W/PMP RELAY) |

| NG | .gif) | REPLACE RELAY (INV W/PMP) |

|

18. | CHECK INSTALLATION CONDITION (INV W/PMP FUSE) |

(a) Check installation condition of the INV W/PMP fuse.

OK:

INV W/PMP fuse is installed correctly.

| NG | .gif) | GO TO STEP 25 |

|

|

19. | CHECK FUSE (INV W/PMP) |

(a) Remove the INV W/PMP fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

INV W/PMP fuse | Always |

Below 1 Ω |

(c) Install the INV W/PMP fuse.

| OK | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (IGCT NO. 2 FUSE HOLDER TERMINAL) |

| NG | .gif) | GO TO STEP 26 |

|

20. | CHECK RELAY HOLDER TERMINAL (INV W/PMP RELAY) |

(a) Check the terminals of the INV W/PMP relay holder.

OK:

The terminals of the INV W/PMP relay holder are not bent, loose or corroded.

| OK | .gif) | REPLACE RELAY (INV W/PMP) |

| NG | .gif) | GO TO STEP 27 |

|

21. | CHECK INSTALLATION CONDITION (INV W/PMP NO. 2 FUSE) |

(a) Check installation condition of the INV W/PMP NO. 2 fuse.

OK:

INV W/PMP NO. 2 fuse is installed correctly.

| NG | .gif) | CONNECT SECURELY (INV W/PMP NO. 2 FUSE) |

|

|

22. | INSPECT RELAY (INV W/PMP) |

(a) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Install the INV W/PMP relay.

| NG | .gif) | GO TO STEP 32 |

|

|

23. | CHECK HARNESS AND CONNECTOR (INVERTER WATER PUMP ASSEMBLY CIRCUIT) |

(a) Remove the INV W/PMP NO. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Disconnect the inverter water pump assembly connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A184-4 (+BWP) - 3 (INV W/PMP relay holder) |

Ignition switch off |

Below 1 Ω |

|

2 (INV W/PMP NO. 2 fuse holder) - 5 (INV W/PMP relay holder) |

Ignition switch off |

Below 1 Ω |

|

2 (INV W/PMP NO. 2 fuse holder) or A184-4 (+BWP) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

NOTICE:

Do not apply excessive force when using the probes of the tester to perform the inspection. If excessive force is used, the terminals will be damaged.

(e) Reconnect the inverter water pump assembly connector.

(f) Install the INV W/PMP relay and INV W/PMP NO. 2 fuse.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

24. | CHECK FUSE (INV W/PMP NO. 2) |

(a) Remove the INV W/PMP NO. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

INV W/PMP NO. 2 fuse |

Always | Below 1 Ω |

(c) Install the INV W/PMP NO. 2 fuse.

| OK | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (INV W/PMP NO. 2 FUSE HOLDER TERMINAL OR INV W/PMP RELAY HOLDER TERMINAL) |

| NG | .gif) | GO TO STEP 28 |

|

25. | INSPECT RELAY (INV W/PMP) |

(a) Remove the INV W/PMP relay from the No. 1 engine room relay block and No. 1 junction block assembly.

| (b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) Install the INV W/PMP relay.

| OK | .gif) | CONNECT SECURELY (INV W/PMP FUSE) |

| NG | .gif) | GO TO STEP 30 |

|

26. | CHECK FUSE HOLDER TERMINAL (INV W/PMP FUSE) |

(a) Check the terminals of the INV W/PMP fuse holder.

OK:

The terminals of the INV W/PMP fuse holder are not bent, loose or corroded.

| OK | .gif) | REPLACE FUSE (INV W/PMP) |

| NG | .gif) | GO TO STEP 31 |

|

27. | REPAIR OR REPLACE HARNESS OR CONNECTOR (INV W/PMP RELAY HOLDER TERMINAL) |

(a) Repair or replace the terminals of the INV W/PMP relay holder.

| NEXT | .gif) | REPLACE RELAY (INV W/PMP) |

|

28. | REPLACE INVERTER WATER PUMP ASSEMBLY |

Click here .gif)

|

|

29. | ADD HV COOLANT AND PERFORM AIR BLEEDING |

(a) After replacing the inverter water pump assembly, add HV coolant and perform air bleeding.

Click here .gif)

| NEXT | .gif) | REPLACE FUSE (INV W/PMP NO. 2) |

|

30. | REPLACE RELAY (INV W/PMP) |

| NEXT | .gif) | CONNECT SECURELY (INV W/PMP FUSE) |

|

31. | REPAIR OR REPLACE HARNESS OR CONNECTOR (INV W/PMP FUSE HOLDER TERMINAL) |

(a) Repair or replace the terminals of the INV W/PMP fuse holder.

| NEXT | .gif) | REPLACE FUSE (INV W/PMP) |

|

32. | CHECK RELAY HOLDER TERMINAL (INV W/PMP RELAY) |

(a) Check the terminals of the INV W/PMP relay holder.

OK:

The terminals of the INV W/PMP relay holder are not bent, loose or corroded.

| NG | .gif) | GO TO STEP 34 |

|

|

33. | CHECK FUSE (INV W/PMP) |

(a) Remove the INV W/PMP fuse No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

INV W/PMP fuse | Always |

Below 1 Ω |

(c) Install the INV W/PMP fuse.

| OK | .gif) | REPLACE RELAY (INV W/PMP) |

| NG | .gif) | GO TO STEP 36 |

|

34. | CHECK FUSE (INV W/PMP) |

(a) Remove the INV W/PMP fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

INV W/PMP fuse | Always |

Below 1 Ω |

(c) Install the INV W/PMP fuse.

| NG | .gif) | GO TO STEP 37 |

|

|

35. | REPAIR OR REPLACE HARNESS OR CONNECTOR (INV W/PMP RELAY HOLDER TERMINAL) |

(a) Repair or replace the terminals of the INV W/PMP relay holder.

| NEXT | .gif) | REPLACE RELAY (INV W/PMP) |

|

36. | REPLACE RELAY (INV W/PMP) |

| NEXT | .gif) | REPLACE FUSE (INV W/PMP) |

|

37. | REPAIR OR REPLACE HARNESS OR CONNECTOR (INV W/PMP RELAY HOLDER TERMINAL) |

(a) Repair or replace the terminals of the INV W/PMP relay holder.

|

|

38. | REPLACE RELAY (INV W/PMP) |

| NEXT | .gif) | REPLACE FUSE (INV W/PMP) |

.gif)