Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

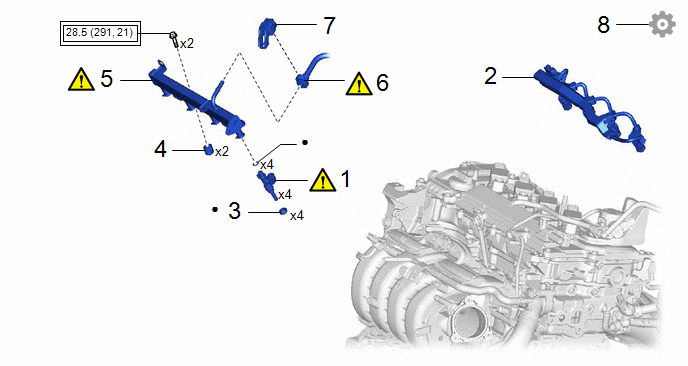

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | PORT FUEL INJECTOR ASSEMBLY |

23250F |

|

- | - |

|

2 | NO. 5 ENGINE WIRE |

82125N | - |

- | - |

|

3 | INJECTOR VIBRATION INSULATOR |

23291 | - |

- | - |

|

4 | FUEL DELIVERY SPACER |

23891 | - |

- | - |

|

5 | FUEL DELIVERY PIPE SUB-ASSEMBLY |

23807 |

|

- | - |

|

6 | FUEL TUBE SUB-ASSEMBLY |

23910A |

|

- | - |

|

7 | FUEL PIPE CLAMP |

23841K | - |

- | - |

|

8 | PERFORM INITIALIZATION |

- | - |

- |

|

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

PROCEDURE

1. INSTALL PORT FUEL INJECTOR ASSEMBLY

.png) |

NOTICE: Perform "Inspection After Repair" after replacing a port fuel injector assembly. Click here |

.png)

|

*a | Stopper |

*b | Claw |

(1) Apply a light coat of spindle oil or gasoline to 4 new O-rings, and install one to each port fuel injector assembly.

NOTICE:

Check that there is no damage or foreign matter on the groove of the port fuel injector assembly when installing the O-ring to each port fuel injector assembly.

(2) Install the 4 port fuel injector assemblies to the fuel delivery pipe sub-assembly.

NOTICE:

- Make sure that the port fuel injector assembly is located within the stopper as shown in the illustration.

- Check that the port fuel injector assembly installation holes of the fuel delivery pipe sub-assembly are not damaged and are free of foreign matter.

- Make sure that the O-ring is not damaged, twisted or moved out of place when installing the port fuel injector assembly.

2. INSTALL NO. 5 ENGINE WIRE

3. INSTALL INJECTOR VIBRATION INSULATOR

4. INSTALL FUEL DELIVERY SPACER

5. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

.png)

(1) Place the fuel delivery pipe sub-assembly with the 4 port fuel injector assemblies onto the cylinder head sub-assembly.

NOTICE:

Be careful not to drop the port fuel injector assemblies when installing the fuel delivery pipe sub-assembly.

(2) Install the fuel delivery pipe sub-assembly with the port fuel injector assemblies with the 2 bolts.

Torque:

28.5 N·m {291 kgf·cm, 21 ft·lbf}

(3) Connect the No. 5 engine wire connector.

6. CONNECT FUEL TUBE SUB-ASSEMBLY

.png)

(1) Connect the fuel tube sub-assembly to the fuel delivery pipe sub-assembly.

Click here .gif)

7. INSTALL FUEL PIPE CLAMP

8. PERFORM INITIALIZATION

(a) Perform "Inspection After Repair" after replacing a port fuel injector assembly.

Click here .gif)