Toyota Corolla Cross: Freeze Frame Data

FREEZE FRAME DATA

DESCRIPTION

The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

HINT:

- If it is impossible to replicate the problem even though a DTC is detected, confirm the Freeze Frame Data.

- Freeze Frame Data is available in long and short forms.

PENDING FREEZE FRAME DATA

HINT:

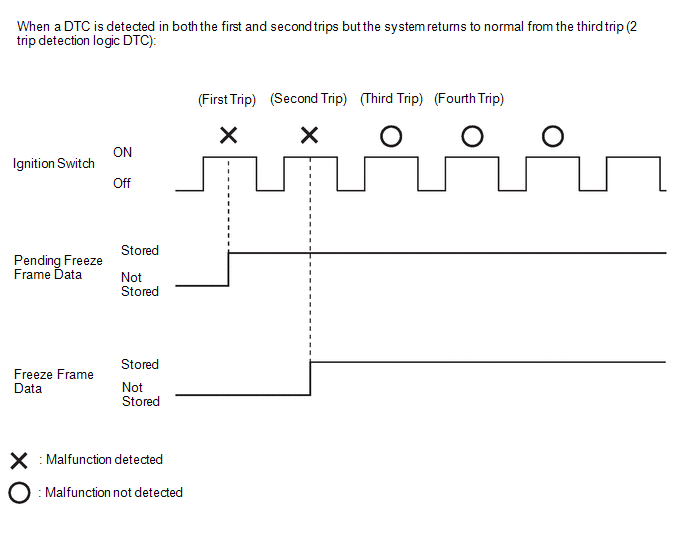

Pending Freeze Frame Data is stored when a 2 trip detection logic DTC is first detected during the first trip.

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the GTS on.

(d) Enter the following menus: Powertrain / Engine / Trouble Codes.

(e) Select a DTC in order to display its pending Freeze Frame Data.

Powertrain > Engine > Trouble CodesHINT:

- Pending Freeze Frame Data is cleared when any of the following occurs.

- Using the GTS, the DTCs are cleared.

- The cable is disconnected from the negative (-) auxiliary battery terminal.

- 40 trips with the engine fully warmed up have been performed after returning to normal. (Pending Freeze Frame Data will not be cleared by only returning the system to normal.)

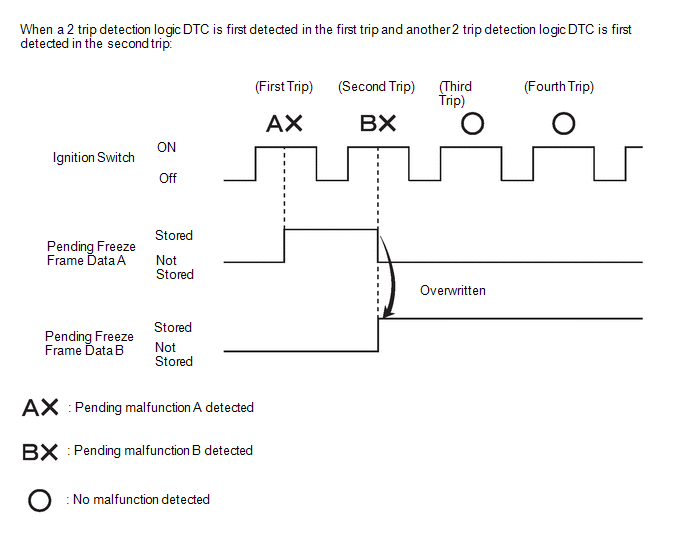

- With previous pending Freeze Frame Data stored, if pending Freeze Frame Data is newly stored when a 2 trip detection logic DTC is detected in the first trip, the old Freeze Frame Data will be replaced with the new data of the newly detected DTC in the next trip.

LIST OF FREEZE FRAME DATA

Powertrain > Engine|

Tester Display |

|---|

| Total Distance Traveled |

|

Total Distance Traveled - Unit |

|

Key Cycle |

| Elapsed Time |

|

Vehicle Speed |

| Engine Speed |

|

Calculate Load |

| Vehicle Load |

|

Mass Air Flow Sensor |

|

Atmospheric Pressure |

|

Intake Manifold Absolute Pressure |

|

Intake Manifold Absolute Pressure Supported |

|

Engine Oil Temperature Sensor |

|

Coolant Temperature |

|

Intake Air Temperature |

|

Ambient Temperature |

|

Engine Run Time |

|

IG-ON Coolant Temperature |

|

Initial Engine Coolant Temperature |

|

IG-ON Intake Air Temperature |

|

Initial Engine Intake Air Temperature |

|

Battery Voltage |

|

BATT Voltage |

|

IG2 / IGP |

| IGR |

|

Engine Oil Pressure |

|

Target Engine Oil Pressure |

|

Engine Oil Pressure Control Valve |

|

Intake Camshaft Position Sensor Voltage |

|

Exhaust Camshaft Position Sensor Voltage |

|

Crankshaft Position Sensor Voltage |

|

Throttle Position Sensor No.1 Voltage % |

|

Throttle Position Sensor No.2 Voltage % |

|

System Guard |

|

Open Side Malfunction |

|

Throttle Request Position |

|

Throttle Sensor Position |

|

Throttle Position Sensor No.1 Voltage |

|

Throttle Position Sensor No.2 Voltage |

|

Throttle Position Command |

|

Throttle Position Sensor Open Position No.1 |

|

Throttle Position Sensor Open Position No.2 |

|

Throttle Motor Current |

|

Throttle Motor Duty Ratio |

|

Throttle Motor Duty Ratio (Open) |

|

Throttle Motor Duty Ratio (Close) |

|

Throttle Position Sensor Fully Closed Learn Value |

|

+BM Voltage |

|

Actuator Power Supply |

|

Throttle Air Flow Learn Value (Area 1) |

|

Throttle Air Flow Learn Value (Area 2) |

|

Throttle Air Flow Learn Value (Area 3) |

|

Throttle Air Flow Learn Value (Calculated Value) |

|

Throttle Air Flow Learn Value (Atmosphere Pressure Offset Value) |

|

Low Revolution Control |

|

Engine Stall Control F/B Flow |

|

Target Fuel Pressure (High) |

|

Target Fuel Pressure (High) Supported |

|

Target Fuel Pressure (Low) / Target Fuel Pressure 2 |

|

Target Fuel Pressure (Low) / Target Fuel Pressure 2 Supported |

|

Fuel Pressure (High) |

|

Fuel Pressure (High) Supported |

|

Fuel Pressure (Low) / Fuel Pressure 2 |

|

Fuel Pressure (Low) / Fuel Pressure 2 Supported |

|

VSV for Vent Valve |

|

Vacuum Pump |

|

Fuel Pump Target Speed |

|

Fuel Pump F/B Offset |

|

Fuel Pump Control Duty Ratio |

|

Low Pressure Fuel Delivery Internal Temperature |

|

Injector Cylinder #1 (Port) |

|

Injection Volume Cylinder #1 |

|

Target Fuel Pressure Offset |

|

Injection Volume |

|

Low Fuel Pressure Sensor |

|

High Fuel Pressure Sensor |

|

High Pressure Fuel Pump Duty Ratio (D4) |

|

High Pressure Fuel Pump Discharge Rate |

|

High Pressure Fuel Pump Internal Temperature |

|

Injection Mode |

|

Injection Switching Status |

|

Injection Timing Cylinder #1 (D4) |

|

Injection Time Cylinder #1 (D4) |

|

Current Fuel Type |

|

EVAP (Purge) VSV |

|

Fuel Filler Opener |

|

Fuel Vapor-Containment Valve |

|

Fuel Lid SW |

|

Fuel Lid Sensor SW |

|

Fuel Tank Internal Pressure |

|

Vapor Pressure when Fuel Tank Leak Check Finished |

|

Fuel Tank Leak Check Time Required |

|

Vapor Pressure 1 during Fuel Tank Side Pressure Applied |

|

Vapor Pressure 2 during Fuel Tank Side Pressure Applied |

|

EVAP System Vapor Pressure 1 Supported |

|

EVAP System Vapor Pressure 2 Supported |

|

EVAP System Vapor Pressure 1 (Wide Range) |

|

EVAP System Vapor Pressure 1 (Wide Range) Supported |

|

EVAP System Vapor Pressure 2 (Wide Range) Supported |

|

Target Air-Fuel Ratio |

|

A/F (O2) Lambda Sensor B1S1 |

|

A/F (O2) Lambda Sensor B1S2 |

|

A/F (O2) Sensor Current B1S1 |

|

A/F (O2) Sensor Current B1S2 |

|

A/F (O2) Sensor Heater Duty Ratio B1S1 |

|

A/F Sensor Heater Current Value B1S2 |

|

A/F Sensor Heater Duty B1S2 |

|

A/F Sensor Impedance B1S1 |

|

A/F Sensor Impedance B1S2 |

|

A/F (O2) Sensor +Terminal Voltage Bank 1 |

|

A/F (O2) Sensor -Terminal Voltage Bank 1 |

|

A/F (O2) Sensor Heater Control Duty Ratio Bank1 |

|

A/F (O2) Sensor Heater Output Duty Ratio Bank1 |

|

A/F (O2) Sensor Heater ON Current Value Bank1 |

|

A/F (O2) Sensor Heater Current-Carrying Status Bank1 (at Heater OFF) |

|

A/F (O2) Sensor Heater Overcurrent Bank1 |

|

A/F (O2) Sensor Heater Control Run Time Bank1 |

|

Short FT B1S1 |

|

Short FT B1S2 |

|

Long FT B1S1 |

|

Long FT B1S2 |

|

Total FT Bank 1 |

|

Fuel System Status Bank 1 |

|

Fuel System Status Bank 2 |

|

Ignition Timing Cylinder #1 |

|

Knock F/B Value |

|

Knock Correct Learn Value |

|

Idle Spark Advance Control Cylinder #1 |

|

Idle Spark Advance Control Cylinder #2 |

|

Idle Spark Advance Control Cylinder #3 |

|

Idle Spark Advance Control Cylinder #4 |

|

Mass Air Flow Circuit |

|

Target EGR Valve Position No.1 |

|

Target EGR Valve Position No.1 Supported |

|

Actual EGR Valve Position No.1 Supported |

|

Target EGR Valve Position No.2 Supported |

|

Actual EGR Valve Position No.2 Supported |

|

EGR Step Position |

|

VVT Advance Fail |

|

Exhaust VVT Retarded Fail |

|

Intake VVT Change Angle Bank 1 |

|

Exhaust VVT Hold Learn Value Bank 1 |

|

Exhaust VVT Change Angle Bank 1 |

|

Exhaust VVT OCV Control Duty Ratio Bank 1 |

|

Intake VVT Target Angle Bank 1 |

|

Exhaust VVT Target Angle Bank 1 |

|

Intake VVT Timing Most Over-Retarded Learn Value Bank 1 |

|

Exhaust VVT Timing Most Over-Advanced Learn Value Bank 1 |

|

VVT-iE Duty Ratio Bank 1 |

|

VVT-iE Motor Direction Bank 1 |

|

Catalyst Temperature B1S1 |

|

Catalyst Temperature B1S2 |

|

TC Terminal |

|

MIL ON Run Distance |

|

Running Time from MIL ON |

|

Time after DTC Cleared |

|

Distance from DTC Cleared |

|

Warmup Cycle Cleared DTC |

|

Distance Traveled from Last Battery Cable Disconnect |

|

IG OFF Elapsed Time |

|

Soak IC Current Timer Value |

|

Soak IC First Start Time |

|

Soak Timer Start History |

|

Ignition Trigger Count |

|

Misfire Count Cylinder #1 |

|

Misfire Count Cylinder #2 |

|

Misfire Count Cylinder #3 |

|

Misfire Count Cylinder #4 |

|

All Cylinders Misfire Count |

|

Misfire RPM |

|

Misfire Load |

|

Misfire Margin |

|

Catalyst OT Misfire Fuel Cut |

|

Catalyst OT Misfire Fuel Cut History |

|

Catalyst OT Misfire Fuel Cut Cylinder #1 |

|

Catalyst OT Misfire Fuel Cut Cylinder #2 |

|

Catalyst OT Misfire Fuel Cut Cylinder #3 |

|

Catalyst OT Misfire Fuel Cut Cylinder #4 |

|

A/F Learn Value Idle (Port) Bank 1 |

|

A/F Learn Value Low (Port) Bank 1 |

|

A/F Learn Value Mid No.1 (Port) Bank 1 |

|

A/F Learn Value Mid No.2 (Port) Bank 1 |

|

A/F Learn Value High (Port) Bank 1 |

|

IG ON Duration Time |

|

IG OFF Duration Time |

|

Engine Start Hesitation |

|

Low Revolution for Engine Start |

|

A/F Learn Value Idle Bank 1 |

|

A/F Learn Value Low Bank 1 |

|

A/F Learn Value Mid No.1 Bank 1 |

|

A/F Learn Value Mid No.2 Bank 1 |

|

A/F Learn Value High Bank 1 |

|

Engine ECU Internal Temperature |

|

Engine Cooling Fan |

|

Engine Speed Cylinder #1 |

|

Engine Speed Cylinder #2 |

|

Engine Speed Cylinder #3 |

|

Engine Speed Cylinder #4 |

|

Average Engine Speed of All Cylinder |

|

A/F Sensor Determination (Worst Value) Bank 1 |

|

Engine Speed Fluctuation Average (Worst Value) Cylinder #1 |

|

Engine Speed Fluctuation Average (Worst Value) Cylinder #2 |

|

Engine Speed Fluctuation Average (Worst Value) Cylinder #3 |

|

Engine Speed Fluctuation Average (Worst Value) Cylinder #4 |

|

A/F Sensor Determination (Worst Value) (Port) Bank 1 |

|

Engine Speed Fluctuation Average (Worst Value) (Port) Cylinder #1 |

|

Engine Speed Fluctuation Average (Worst Value) (Port) Cylinder #2 |

|

Engine Speed Fluctuation Average (Worst Value) (Port) Cylinder #3 |

|

Engine Speed Fluctuation Average (Worst Value) (Port) Cylinder #4 |

|

Requested Engine Torque |

|

HV Target Engine Speed |

|

Actual Engine Torque |

|

Engine Driving Time |

|

Request Engine Run Time |

|

Judge Time Engine Ignition |

|

Judge Time Engine Output |

|

Fuel Level |

| ISC Learning Value |

|

ISC Learning |

| F/C for Engine Stop Req |

|

Engine Independent |

|

Racing Operation |

|

Request Warm-up |

|

Engine Independent Control |

|

Electric Water Pump Target Speed |

|

Electric Water Pump Speed |