Toyota Corolla Cross: Backup Boost Converter "A" Control CPU Signal Invalid (P060629)

DESCRIPTION

The engine stop and start ECU can detect open circuits when signals such as the boost, standby request or overheating signal cannot be sent to the backup boost converter control IC from the stop and start control IC in the engine stop and start ECU.

If a CPU duty malfunction is detected, the engine stop and start ECU stores DTC P060629.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Warning Indicate |

Note |

|---|---|---|---|---|---|---|

| P060629 |

Backup Boost Converter "A" Control CPU Signal Invalid |

The following condition continues for 1 second or more (2 trip detection logic):

|

| Comes on (For Mexico Models: Does not come on) |

Does not come on (For Mexico Models: Blinks) |

SAE Code: P0606 |

MONITOR STRATEGY

|

Related DTCs | P0606: Control module processer (starter / generator control module) performance |

|

Required Sensors/Components (Main) | Engine stop and start ECU |

|

Required Sensors/Components (Related) | - |

|

Frequency of Operation | Continuous |

|

Duration | 1 second |

| MIL Operation |

2 driving cycles |

| Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

All of the following conditions are met |

- |

| Battery voltage |

8 V or higher |

|

Write Inhibit | permit |

|

Time after Write status forbiddance to permit |

0.5 seconds or more |

|

Ignition switch | ON |

|

Time after ignition switch is off to ON |

0.5 seconds or more |

|

Starter | Off |

|

Time after starter on to off | 0.5 seconds or more |

|

Engine stop and start ECU internal back up boost converter fail (P323C) |

Not detected |

TYPICAL MALFUNCTION THRESHOLDS

Case 1|

Back up boost converter command frequency |

Less than 92.59 Hz |

|

The following condition is met | 5 times or more |

|

Back up boost converter command frequency |

Higher than 108.7 Hz |

|

Either of the following conditions (a) or (b) is met |

- |

| (a) Back up boost converter command duty cycle |

24% or less |

| (b) Back up boost converter command duty cycle |

85% or more |

CONFIRMATION DRIVING PATTERN

HINT:

- If the cable is disconnected from the auxiliary battery terminal, stop and start control is prohibited until refresh charge is completed.

In this case, let the vehicle idle to complete the refresh charge. The refresh charge is complete when the Data List item Status of Battery Charge Control changes from "Refresh Charge Mode". (Usually, by idling the engine for 5 to 60 minutes with the auxiliary battery fluid temperature at 11°C (52°F) or higher, the refresh charge will be completed.)

- If the GTS is not available and the Data List item Status of Battery Charge Control cannot be checked, charge the auxiliary battery by idling the engine for approximately 5 to 60 minutes or driving the vehicle, and then drive the vehicle and check that stop and start control operates.

If the engine is started with the hood open, the system determines that a jump start has occurred. Therefore, make sure that the hood is closed before starting the engine and driving the vehicle.

- After the refresh charge completes, turn the ignition switch off, wait for at least 30 seconds, and then start the engine again. If the vehicle enters refresh charge mode again while the engine is idling, the initial refresh charge did not properly complete, so wait for the refresh charge to complete.

- Allow the engine to idle for 3 minutes after it is warmed up and check that the engine idle speed is within 50 rpm of the target idle speed.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure (except Mexico Models).

Click here

.gif)

- When clearing the permanent DTCs, do not disconnect the cable from the battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories (except Mexico Models).

CONFIRMATION AFTER TROUBLESHOOTING

(a) Clear the DTCs.

Powertrain > Stop and Start > Clear DTCs(b) Start the engine and warm it up.

(c) Drive the vehicle at 7 km/h (4 mph) or more.

CAUTION:

When performing Confirmation Driving Pattern, obey all speed limits and traffic laws.

(d) Depress the brake pedal and stop the vehicle.

(e) Keep the engine stopped by stop and start control for 1 second or more. (Keep the shift lever in D.)

(f) Release the brake pedal with the shift lever in D to start the engine.

HINT:

If the engine cranks slowly when the engine is restarted, it can be determined that the auxiliary battery voltage is low.

(g) Check that DTCs are not output.

Powertrain > Stop and Start > Trouble CodesSTOP AND START SYSTEM OPERATION CHECK

Click here

.gif)

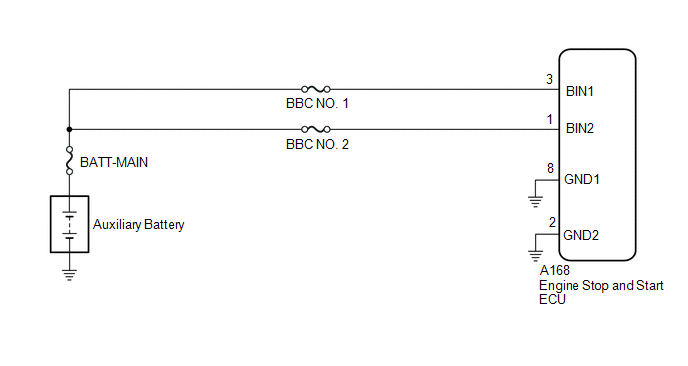

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Before replacing the engine stop and start ECU, read the number of starter operations and write it into a new engine stop and start ECU.

Click here

.gif)

- After replacing the engine stop and start ECU, perform learning of the external backup boost converter (eco run vehicle converter assembly).

Click here

.gif)

- After replacing the engine stop and start ECU or air conditioning amplifier assembly, reset and perform learning of the air conditioning information in the engine stop and start ECU.

Click here

.gif)

- When the engine stop and start ECU or oil pump with motor assembly is replaced, check the oil pump with motor assembly.

Click here

.gif)

- Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

- Using the GTS, read the freeze frame data before troubleshooting. System condition information is recorded as freeze frame data the moment a DTC is stored. This information can be useful when troubleshooting.

Click here

.gif)

- For wire harness and connector inspection procedures and precautions, refer to "Click here

.gif) "

"

- DTCs for the stop and start system are not cleared even if the malfunction has been repaired. After repairing the malfunction, be sure to clear the DTCs.

PROCEDURE

|

1. | CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - AUXILIARY BATTERY) |

(a) Disconnect the A168 engine stop and start ECU connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A168-1 (BIN2) - Body ground |

Always | 9.5 to 14 V |

|

A168-3 (BIN1) - Body ground |

Always | 9.5 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 2. |

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - BODY GROUND) |

(a) Disconnect the A168 engine stop and start ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A168-2 (GND2) - Body ground |

Always | Below 1 Ω |

|

A168-8 (GND1) - Body ground |

Always | Below 1 Ω |

| OK | .gif) | REPLACE ENGINE STOP AND START ECU |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)