Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | COOLER CONDENSER ASSEMBLY |

884A0 |

|

- | - |

|

2 | AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY |

88710E |

|

- | - |

|

3 | DISCHARGE HOSE SUB-ASSEMBLY |

88703 |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

.png) |

for Gasoline Model: Compressor oil ND-OIL 12 or equivalent for HEV Model: Compressor oil ND-OIL 11 or equivalent |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

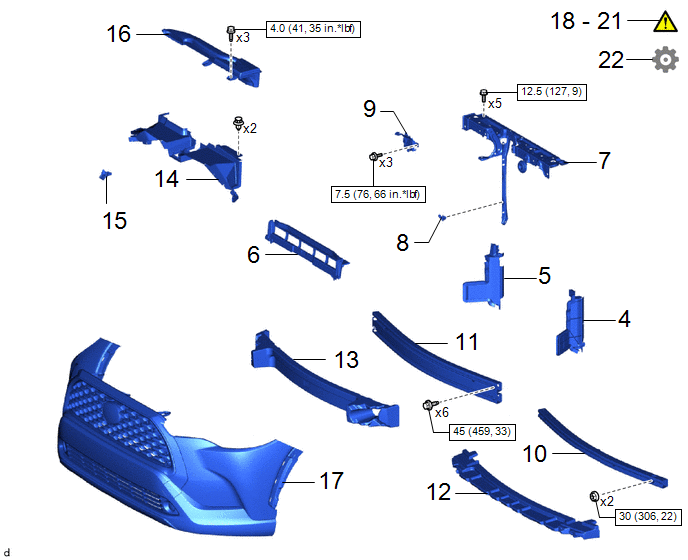

4 | NO. 1 RADIATOR AIR GUIDE LH |

16595D | - |

- | - |

|

5 | NO. 1 RADIATOR AIR GUIDE RH |

16593D | - |

- | - |

|

6 | NO. 2 RADIATOR AIR GUIDE |

16594A | - |

- | - |

|

7 | UPPER RADIATOR SUPPORT SUB-ASSEMBLY WITH HOOD LOCK SUPPORT SUB-ASSEMBLY |

- | - |

- | - |

|

8 | THERMISTOR ASSEMBLY |

88790B | - |

- | - |

|

9 | HOOD LOCK ASSEMBLY WITH COURTESY LIGHT SWITCH |

53510G | - |

- | - |

|

10 | NO. 2 FRONT BUMPER REINFORCEMENT |

52132A | - |

- | - |

|

11 | FRONT BUMPER REINFORCEMENT |

52131A | - |

- | - |

|

12 | FRONT BUMPER LOWER ABSORBER |

52618 | - |

- | - |

|

13 | FRONT BUMPER ENERGY ABSORBER |

52611 | - |

- | - |

|

14 | NO. 1 RADIATOR TO SUPPORT SEAL |

16561C | - |

- | - |

|

15 | LOWER NO. 2 FRONT BUMPER RETAINER |

52527C | - |

- | - |

|

16 | INLET NO. 1 AIR CLEANER |

17751 | - |

- | - |

|

17 | FRONT BUMPER ASSEMBLY |

- | - |

- | - |

|

18 | CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

- |

|

- | - |

|

19 | WARM UP ENGINE |

- |

|

- | - |

|

20 | WARM UP COMPRESSOR |

- |

|

- | - |

|

21 | INSPECT FOR REFRIGERANT LEAK |

- |

|

- | - |

|

22 | ADJUST HOOD SUB-ASSEMBLY |

- | - |

- |

|

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

PROCEDURE

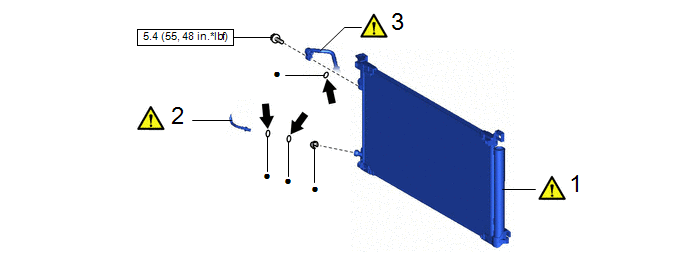

1. INSTALL COOLER CONDENSER ASSEMBLY

.png) |

Install in this Direction |

- | - |

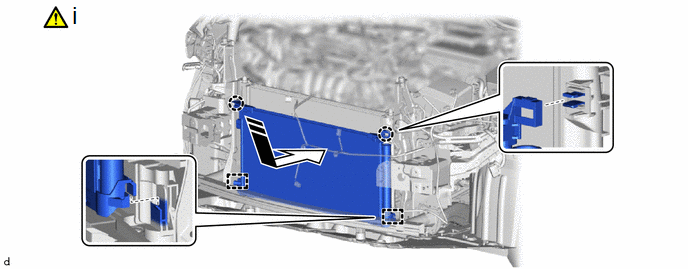

(1) Engage the guides and claws to install the cooler condenser assembly as shown in the illustration.

NOTICE:

Do not damage the cooler condenser assembly or radiator assembly when installing the cooler condenser assembly.

HINT:

If a new cooler condenser assembly is installed, add compressor oil to the cooler condenser assembly as follows.

Capacity:

Add 40 cc (1.35 fl. oz)

Compressor Oil:

for Gasoline Model:

ND-OIL 12 or equivalent

for HEV Model:

ND-OIL 11 or equivalent

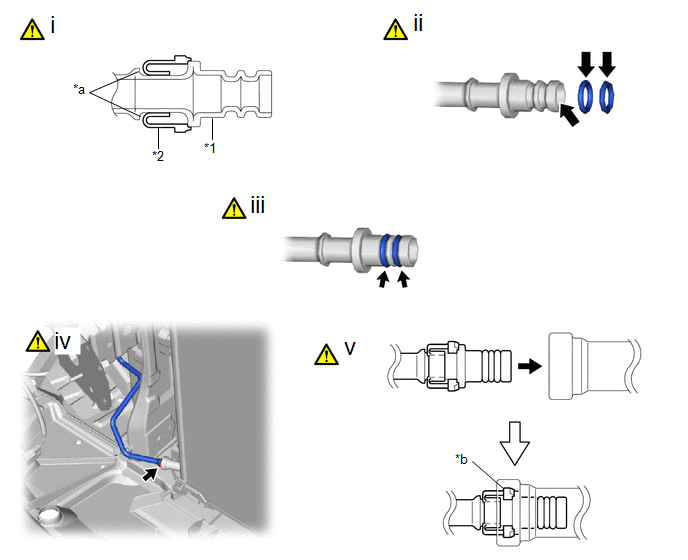

2. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

|

*1 | Air Conditioning Tube and Accessory Assembly |

*2 | Piping Clamp |

|

*a | Groove |

*b | Large Diameter Section of Piping Clamp |

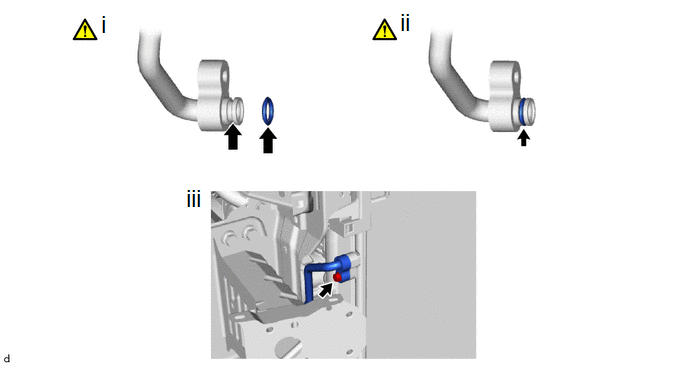

(1) Remove the vinyl tape from the cooler condenser assembly and air conditioning tube and accessory assembly and install a new piping clamp to the air conditioning tube and accessory assembly.

NOTICE:

- Securely engage the piping clamp to the groove of the air conditioning tube and accessory assembly.

- Do not open the piping clamp more than the diameter of the air conditioning tube and accessory assembly when installing it.

- Do not install the piping clamp with the large diameter section facing the wrong direction.

(2) Sufficiently apply compressor oil to 2 new O-rings and the fitting surfaces of the air conditioning tube and accessory assembly.

Compressor Oil:

for Gasoline Model:

ND-OIL 12 or equivalent

for HEV Model:

ND-OIL 11 or equivalent

(3) Install the 2 O-rings to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-rings and O-ring fitting surfaces free from foreign matter.

(4) Connect the air conditioning tube and accessory assembly to the cooler condenser assembly.

NOTICE:

Connect the parts by holding the pipe, not the piping clamp.

(5) Securely insert the piping clamp to the point where the large diameter section of the piping clamp is covered by the cooler condenser assembly.

NOTICE:

- When inserting, make sure that a click sound is heard.

- Check that the air conditioning tube and accessory assembly is securely connected by pulling it.

3. CONNECT DISCHARGE HOSE SUB-ASSEMBLY

(1) Remove the vinyl tape from the discharge hose sub-assembly and cooler condenser assembly and sufficiently apply compressor oil to a new O-ring and the fitting surface of the discharge hose sub-assembly.

Compressor Oil:

for Gasoline Model:

ND-OIL 12 or equivalent

for HEV Model:

ND-OIL 11 or equivalent

(2) Install the O-ring to the discharge hose sub-assembly.

NOTICE:

Keep the O-rings and O-ring fitting surfaces free from foreign matter.

(3) Connect the discharge hose sub-assembly to the cooler condenser assembly with the bolt.

Torque:

5.4 N·m {55 kgf·cm, 48 in·lbf}

4. INSTALL NO. 1 RADIATOR AIR GUIDE LH

5. INSTALL NO. 1 RADIATOR AIR GUIDE RH

6. INSTALL NO. 2 RADIATOR AIR GUIDE

7. INSTALL UPPER RADIATOR SUPPORT SUB-ASSEMBLY WITH HOOD LOCK SUPPORT SUB-ASSEMBLY

Torque:

12.5 N·m {127 kgf·cm, 9 ft·lbf}

8. INSTALL THERMISTOR ASSEMBLY

9. INSTALL HOOD LOCK ASSEMBLY WITH COURTESY LIGHT SWITCH

10. INSTALL NO. 2 FRONT BUMPER REINFORCEMENT

11. INSTALL FRONT BUMPER REINFORCEMENT

12. INSTALL FRONT BUMPER LOWER ABSORBER

13. INSTALL FRONT BUMPER ENERGY ABSORBER

14. INSTALL NO. 1 RADIATOR TO SUPPORT SEAL

15. INSTALL LOWER NO. 2 FRONT BUMPER RETAINER

16. INSTALL INLET NO. 1 AIR CLEANER

17. INSTALL FRONT BUMPER ASSEMBLY

- except Sport Package:

Click here

.gif)

- for Sport Package:

Click here

.gif)

18. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

Click here

.gif)

19. WARM UP ENGINE (for Gasoline Model)

Click here .gif)

20. WARM UP COMPRESSOR (for HEV Model)

Click here .gif)

21. INSPECT FOR REFRIGERANT LEAK

Click here .gif)

22. ADJUST HOOD SUB-ASSEMBLY

Click here .gif)