Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

CAUTION / NOTICE / HINT

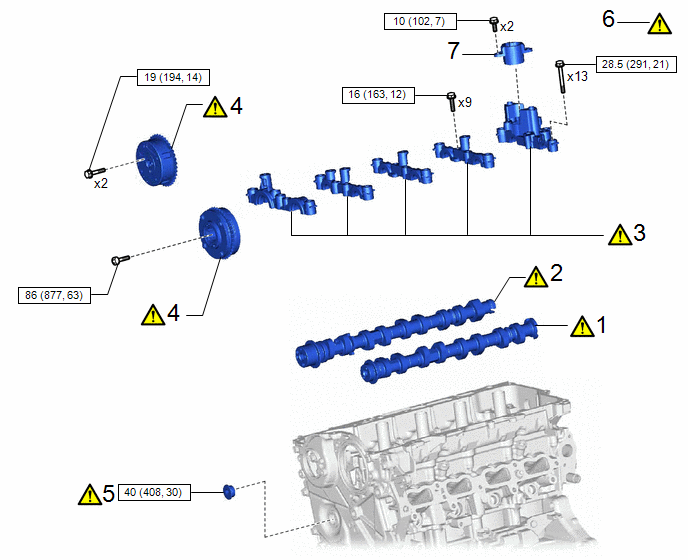

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | EXHAUST CAMSHAFT SUB-ASSEMBLY |

- |

|

- | - |

|

2 | INTAKE CAMSHAFT SUB-ASSEMBLY |

- |

|

- | - |

|

3 | CAMSHAFT BEARING CAP |

- |

|

- | - |

|

4 | CAMSHAFT TIMING GEAR ASSEMBLY |

- |

|

- | - |

|

5 | STRAIGHT SCREW PLUG |

- |

|

- | - |

|

6 | SET NO. 1 CYLINDER TO TDC (COMPRESSION) |

- |

|

- | - |

|

7 | FUEL PUMP LIFTER GUIDE |

23477 | - |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

|

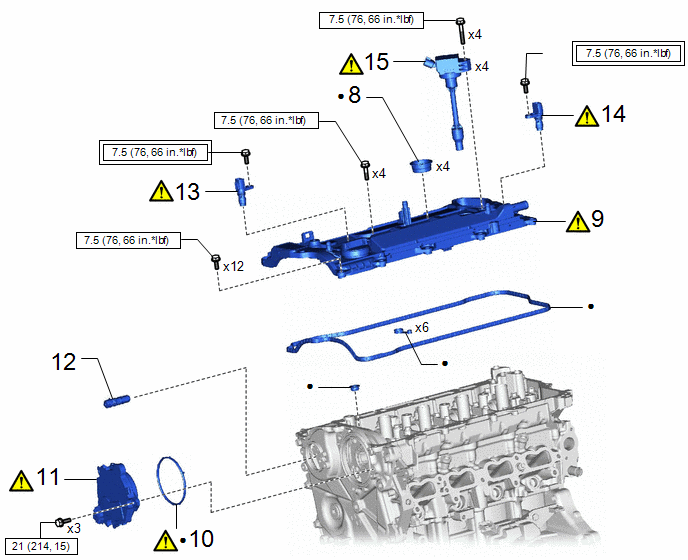

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

8 | SPARK PLUG TUBE GASKET |

11193 | - |

- | - |

|

9 | CYLINDER HEAD COVER SUB-ASSEMBLY |

11201 |

|

- | - |

|

10 | CAM TIMING CONTROL MOTOR O-RING |

13090E |

|

- | - |

|

11 | CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY |

13090D |

|

- | - |

|

12 | CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY) |

- |

|

- | - |

|

13 | CAMSHAFT POSITION SENSOR (for Exhaust Side) |

11102A |

|

- | - |

|

14 | CAMSHAFT POSITION SENSOR (for Intake Side) |

11102A |

|

- | - |

|

15 | IGNITION COIL ASSEMBLY |

19500 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

★ | Precoated part |

|

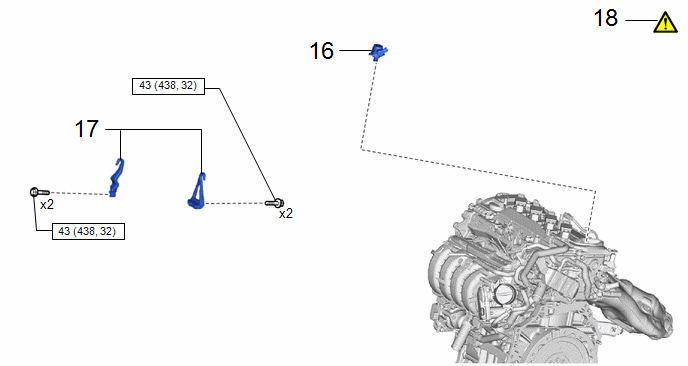

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

16 | FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY |

23100X | - |

- | - |

|

17 | ENGINE HANGERS |

- |

|

- | - |

|

18 | ENGINE ASSEMBLY FROM ENGINE STAND |

- |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

PROCEDURE

1. INSTALL EXHAUST CAMSHAFT SUB-ASSEMBLY

.png) |

HINT: Perform Inspection After Repair after replacing the intake camshaft sub-assembly, exhaust camshaft sub-assembly, camshaft timing gear assembly and camshaft timing exhaust gear assembly. Click here |

.png)

|

*1 | No. 1 Valve Rocker Arm Sub-assembly |

*2 | Valve Lash Adjuster Assembly |

|

*3 | Valve Stem Cap |

- | - |

|

*a | "0" Timing Mark |

*b | Timing Mark |

(1) Turn the crankshaft clockwise to align the timing mark (cutout) on the crankshaft pulley assembly with the "0" timing mark on the No. 2 timing chain cover assembly.

(2) Check that the No. 1 valve rocker arm sub-assembly is correctly installed as shown in the illustration.

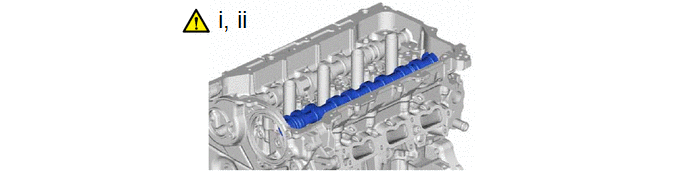

(3) Clean the camshaft housing sub-assembly and the cams and journals of the intake camshaft sub-assembly and exhaust camshaft sub-assembly, and then apply engine oil to them.

(4) Apply a light coat of engine oil to the journals of the exhaust camshaft sub-assembly and install the exhaust camshaft sub-assembly to the camshaft housing sub-assembly.

2. INSTALL INTAKE CAMSHAFT SUB-ASSEMBLY

(1) Clean the camshaft housing sub-assembly and the cams and journals of the intake camshaft sub-assembly, and then apply engine oil to them.

(2) Apply a light coat of engine oil to the journals of the intake camshaft sub-assembly and install the intake camshaft sub-assembly to the camshaft housing sub-assembly.

3. INSTALL CAMSHAFT BEARING CAP

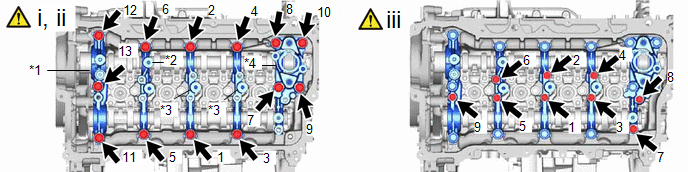

|

*1 | No. 1 Camshaft Bearing Cap |

*2 | No. 2 Camshaft Bearing Cap |

|

*3 | No. 3 Camshaft Bearing Cap |

*4 | No. 4 Camshaft Bearing Cap |

(1) Set the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap, 2 No. 3 camshaft bearing caps and No. 4 camshaft bearing cap as shown in the illustration.

(2) Uniformly tighten the 13 bolts in the order shown in the illustration.

Torque:

28.5 N·m {291 kgf·cm, 21 ft·lbf}

(3) Uniformly tighten the 9 bolts in the order shown in the illustration.

Torque:

16 N·m {163 kgf·cm, 12 ft·lbf}

4. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

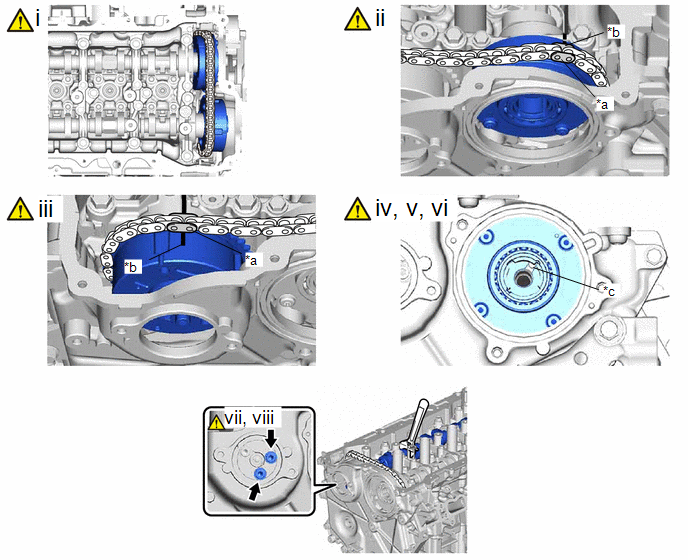

|

*a | Paint Mark |

*b | Timing Mark |

|

*c | Knock Pin |

- | - |

(1) Set the camshaft timing gear assembly and camshaft timing exhaust gear assembly to the chain sub-assembly as shown in the illustration.

(2) Align the timing mark on the camshaft timing gear assembly with the paint mark on the chain sub-assembly.

(3) Align the timing mark on the camshaft timing exhaust gear assembly with the paint mark on the chain sub-assembly.

(4) Using the hexagonal portion of the intake camshaft sub-assembly, install the camshaft timing gear assembly to the intake camshaft sub-assembly.

(5) Check that the knock pin matches the pin hole from the No. 2 timing chain cover sub-assembly side.

(6) Using a 10 mm bi-hexagon socket wrench, temporarily install the camshaft timing gear assembly with the bolt.

HINT:

Temporarily install the bolt enough that the camshaft timing gear assembly does not detach from the knock pin of the intake camshaft sub-assembly.

(7) Using the hexagonal portion of the exhaust camshaft sub-assembly, install the camshaft timing exhaust gear assembly to the exhaust camshaft sub-assembly.

(8) Temporarily install the 2 bolts.

HINT:

The 2 bolts can only be installed as shown in the illustration if the knock pin on the exhaust camshaft sub-assembly and the pin hole on the camshaft timing exhaust gear assembly match. If the 2 bolts cannot be installed, the knock pin and pin hole do not match.

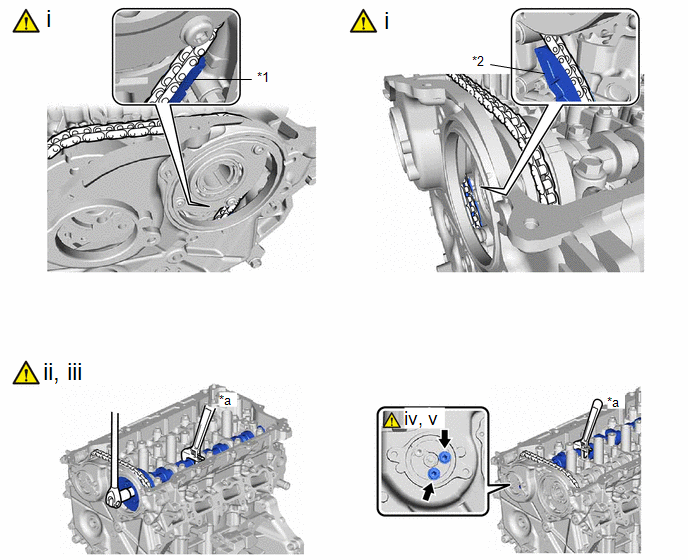

|

*1 | No. 1 Chain Vibration Damper |

*2 | Chain Tensioner Slipper |

|

*a | Hold |

- | - |

(1) Check the status of the camshaft timing gear assembly and camshaft timing exhaust gear assembly temporarily installed to each camshaft.

- Camshaft timing gear assembly side:

Check that the chain sub-assembly does not overlap the No. 1 chain vibration damper as shown in the illustration.

NOTICE:

If the chain sub-assembly overlaps the No. 1 chain vibration damper, install it again.

- Camshaft timing exhaust gear assembly side:

Check that the chain sub-assembly does not overlap the chain tensioner slipper as shown in the illustration.

NOTICE:

If the chain sub-assembly overlaps the chain tensioner slipper, install it again.

(2) Using the hexagonal portion of the intake camshaft sub-assembly, hold the intake camshaft sub-assembly.

NOTICE:

- Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

- Do not disassemble the camshaft timing gear assembly.

(3) Using a 10 mm bi-hexagon socket wrench, tighten the bolt on the camshaft timing gear assembly.

Torque:

86 N·m {877 kgf·cm, 63 ft·lbf}

(4) Using the hexagonal portion of the exhaust camshaft sub-assembly, hold the exhaust camshaft sub-assembly.

NOTICE:

Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

(5) Using a 5 mm hexagon wrench, tighten the 2 bolts.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

.png)

|

*a | Paint Mark |

*b | Timing Mark |

|

*c | Hold |

*d | Pin |

|

*e | Turn |

- | - |

(1) Check that the paint marks and timing marks are positioned as shown in the illustration.

(2) Using the hexagonal portion of the intake camshaft sub-assembly, check that the chain sub-assembly slackens when the intake camshaft sub-assembly is moved in the direction shown in the illustration.

NOTICE:

If the chain sub-assembly remains tight and does not slacken, the chain tensioner slipper and No. 1 chain vibration damper may overlap the chain sub-assembly, so install them again.

(3) Remove the pin from the No. 1 chain tensioner assembly.

5. INSTALL STRAIGHT SCREW PLUG

.png) |

Click here |

6. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

.png) |

Click here |

7. INSTALL FUEL PUMP LIFTER GUIDE

Click here

.gif)

8. INSTALL SPARK PLUG TUBE GASKET

Click here .gif)

9. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

.png) |

Click here |

10. INSTALL CAM TIMING CONTROL MOTOR O-RING

.png) |

Click here |

11. INSTALL CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

.png) |

Click here |

12. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY)

Click here .gif)

13. INSTALL CAMSHAFT POSITION SENSOR (for Exhaust Side)

.png) |

Click here |

14. INSTALL CAMSHAFT POSITION SENSOR (for Intake Side)

.png) |

Click here |

15. INSTALL IGNITION COIL ASSEMBLY

.png) |

Click here |

16. INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY

Click here

.gif)

17. INSTALL ENGINE HANGERS

.png) |

Click here |

18. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

.png) |

Click here |