Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

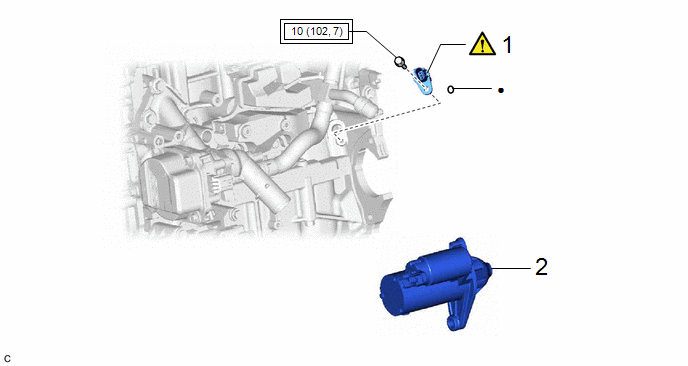

1 | CRANKSHAFT POSITION SENSOR |

11401G |

|

- | - |

|

2 | STARTER ASSEMBLY |

28100 | - |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

1. INSTALL CRANKSHAFT POSITION SENSOR

|

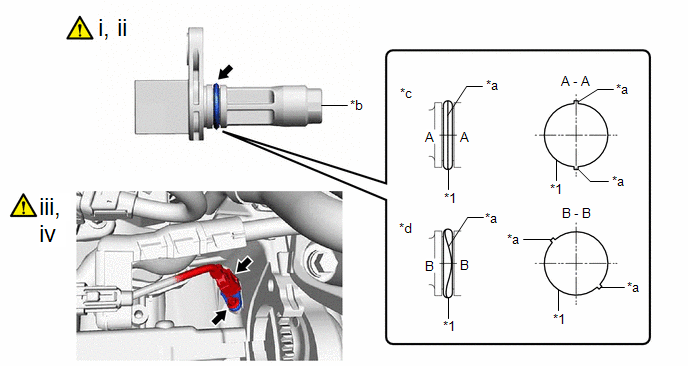

*1 | O-ring |

- | - |

|

*a | Seam |

*b | Crankshaft Position Sensor Tip |

|

*c | OK |

*d | NG |

(1) Perform this procedure only when reusing the crankshaft position sensor.

1. Clean the O-ring groove of the crankshaft position sensor.

NOTICE:

Make sure the O-ring groove is free of foreign matter.

2. Install a new O-ring to the crankshaft position sensor.

NOTICE:

Set the O-ring on the tip of the crankshaft position sensor and roll it into the O-ring groove with bare hands to install it.

3. Check if the O-ring is twisted.

HINT:

Check the entire circumference of the seam of the O-ring for twisting.

(2) Apply a light coat of engine oil to the O-ring of the crankshaft position sensor.

NOTICE:

If reusing the crankshaft position sensor, be sure to inspect the O-ring.

(3) Using an 8 mm socket wrench, install the crankshaft position sensor to the cylinder block sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

NOTICE:

- If the crankshaft position sensor has been struck or dropped, replace it.

- Make sure that the O-ring is not cracked or moved out of place when installing the crankshaft position sensor.

(4) Connect the crankshaft position sensor connector.

2. INSTALL STARTER ASSEMBLY

Click here .gif)

.gif)