Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

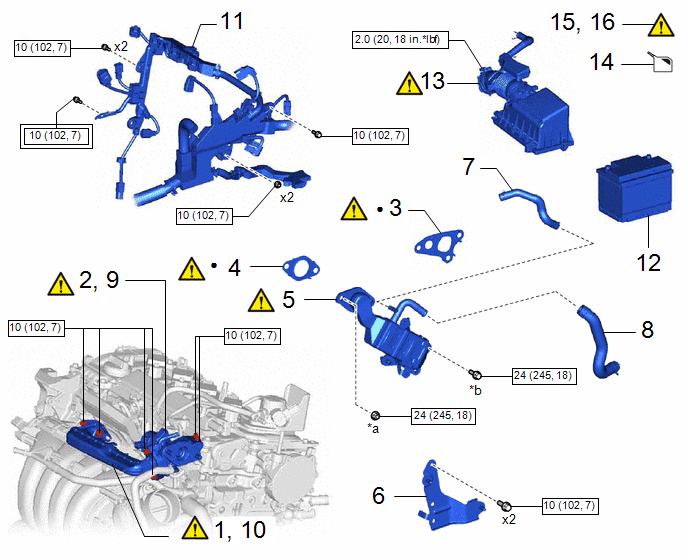

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | LOOSEN NO. 1 EGR PIPE SUB-ASSEMBLY |

25601 |

|

- | - |

|

2 | LOOSEN EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

3 | NO. 1 EGR COOLER GASKET |

25685 |

|

- | - |

|

4 | EGR VALVE GASKET |

25627 |

|

- | - |

|

5 | EGR COOLER ASSEMBLY |

25680 |

|

- | - |

|

6 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

7 | NO. 4 WATER BY-PASS HOSE |

16281 | - |

- | - |

|

8 | NO. 3 WATER BY-PASS HOSE |

16267 | - |

- | - |

|

9 | TIGHTEN EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

10 | TIGHTEN NO. 1 EGR PIPE SUB-ASSEMBLY |

25601 |

|

- | - |

|

11 | ENGINE WIRE |

82121 | - |

- | - |

|

12 | AUXILIARY BATTERY |

- | - |

- | - |

|

13 | AIR CLEANER CAP WITH AIR CLEANER HOSE |

- |

|

- | - |

|

14 | ADD ENGINE COOLANT |

- | - |

|

- |

| 15 |

INSPECT FOR COOLANT LEAK |

- |

|

- | - |

|

16 | INSPECT FOR EXHAUST GAS LEAK |

- |

|

- | - |

|

*a | x2 or x3 |

*b | x3 or x2 |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

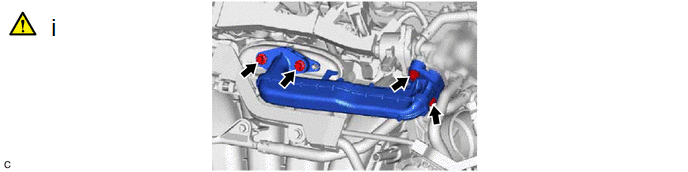

1. LOOSEN NO. 1 EGR PIPE SUB-ASSEMBLY

(1) Using an 8 mm socket wrench, loosen the 4 bolts of the No. 1 EGR pipe sub-assembly.

NOTICE:

- As the bolts of the No. 1 EGR pipe sub-assembly are only to be loosened, it is not necessary to replace the EGR inlet gasket and EGR valve adapter gasket.

- If the No. 1 EGR pipe sub-assembly is removed, it is necessary to replace the EGR inlet gasket and EGR valve adapter gasket with new ones.

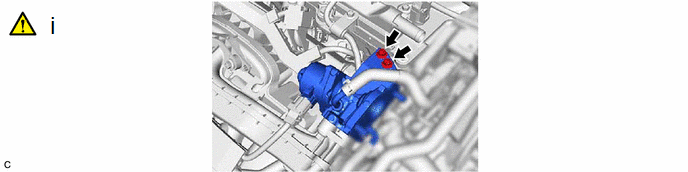

2. LOOSEN EGR VALVE ASSEMBLY

(1) Using an 8 mm socket wrench, loosen the 2 bolts EGR valve assembly.

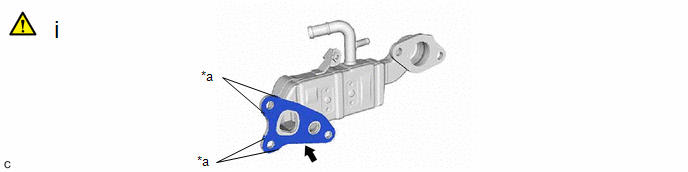

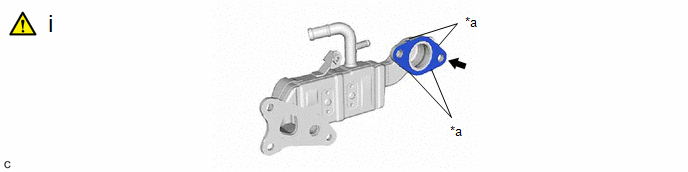

3. INSTALL NO. 1 EGR COOLER GASKET

|

*a | Claw |

- | - |

(1) Install a new No. 1 EGR cooler gasket to the EGR cooler assembly.

NOTICE:

Make sure that the claws of the No. 1 EGR cooler gasket are toward the EGR cooler assembly side.

4. INSTALL EGR VALVE GASKET

|

*a | Claw |

- | - |

(1) Install a new EGR valve gasket to the EGR cooler assembly.

NOTICE:

Make sure that the claws of the EGR valve gasket are toward the EGR cooler assembly side.

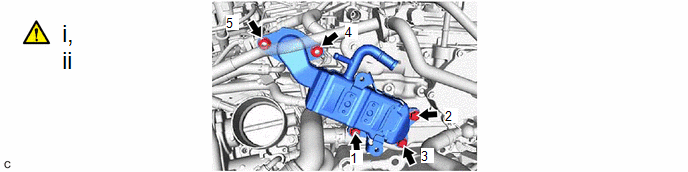

5. INSTALL EGR COOLER ASSEMBLY

[The illustrations are representative examples, and details may differ.]

(1) Temporarily install the EGR cooler assembly to the cylinder head sub-assembly and EGR valve assembly with the bolts and nuts.

(2) Tighten the bolts and nuts in the order shown in the illustration.

Torque:

24 N·m {245 kgf·cm, 18 ft·lbf}

6. INSTALL WIRE HARNESS CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

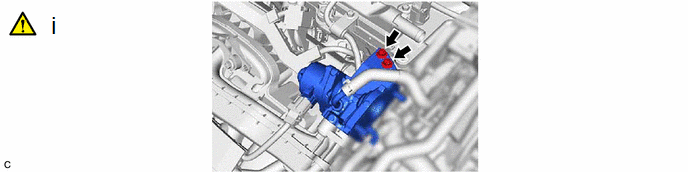

7. CONNECT NO. 4 WATER BY-PASS HOSE

8. CONNECT NO. 3 WATER BY-PASS HOSE

9. TIGHTEN EGR VALVE ASSEMBLY

(1) Using an 8 mm socket wrench, tighten the 2 bolts of the EGR valve assembly.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

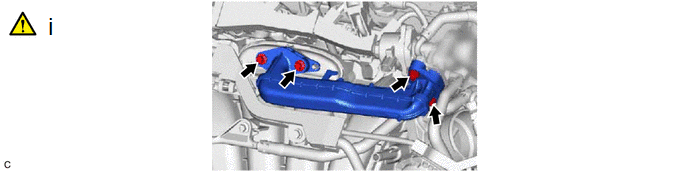

10. TIGHTEN NO. 1 EGR PIPE SUB-ASSEMBLY

(1) Using an 8 mm socket wrench, tighten the 4 bolts of the No. 1 EGR pipe sub-assembly.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

11. CONNECT ENGINE WIRE

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

12. INSTALL AUXILIARY BATTERY

Click here .gif)

.gif)

13. INSTALL AIR CLEANER CAP WITH AIR CLEANER HOSE

.png) |

Click here |

14. ADD ENGINE COOLANT

Click here .gif)

15. INSPECT FOR COOLANT LEAK

Click here

.gif)

16. INSPECT FOR EXHAUST GAS LEAK

Click here .gif)