Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

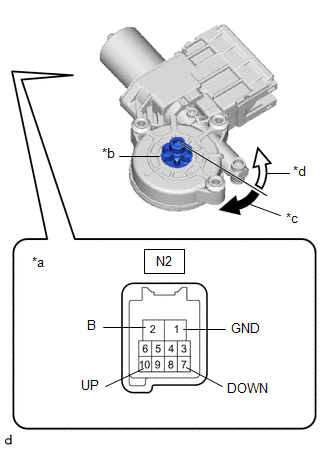

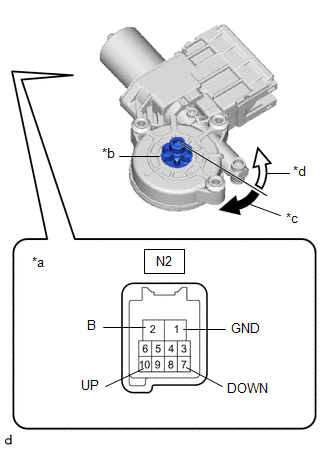

1. INSPECT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH

(a) Check the operation.

|

(1) Connect a positive (+) lead from the auxiliary battery to connector terminal N2-2 (B).

NOTICE: Do not connect a positive (+) lead from the auxiliary battery to any terminal other than terminal N2-2 (B) to avoid damaging the pulse sensor inside the motor. |

|

|

*a | Component without harness connected

(Power Window Regulator Motor Assembly LH) | |

*b | Motor Gear | |

*c | Clockwise | |

*d | Counterclockwise | | |

(2) Connect a negative (-) lead from the auxiliary battery to connector terminals N2-1 (GND) and N2-7 (DOWN) or N2-10 (UP).

(3) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition | Specified Condition |

- Connect a positive (+) lead from the auxiliary battery to terminal N2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal N2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals N2-2 (B) and N2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal N2-10 (UP).

| Motor gear rotates clockwise |

- Connect a positive (+) lead from the auxiliary battery to terminal N2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal N2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals N2-2 (B) and N2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal N2-7 (DOWN).

| Motor gear rotates counterclockwise |

- If the result is not as specified, replace the power window regulator motor assembly LH.

CAUTION:

Initialize the power window control system after installing the rear door window regulator assembly.

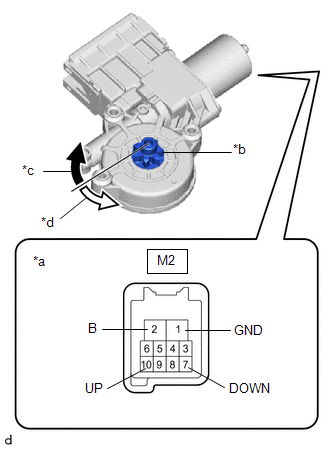

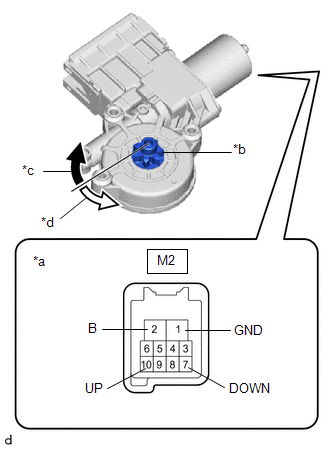

2. INSPECT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH

(a) Check the operation.

| (1) Connect a positive (+) lead from the auxiliary battery to connector terminal M2-2 (B).

NOTICE: Do not connect a positive (+) lead from the auxiliary battery to any terminal other than terminal M2-2 (B) to avoid damaging the pulse sensor inside the motor. |

|

|

*a | Component without harness connected

(Power Window Regulator Motor Assembly RH) | |

*b | Motor Gear | |

*c | Clockwise | |

*d | Counterclockwise | | |

(2) Connect a negative (-) lead from the auxiliary battery to connector terminals M2-1 (GND) and M2-7 (DOWN) or M2-10 (UP).

(3) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition | Specified Condition |

- Connect a positive (+) lead from the auxiliary battery to terminal M2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal M2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals M2-2 (B) and M2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal M2-10 (UP).

| Motor gear rotates counterclockwise |

- Connect a positive (+) lead from the auxiliary battery to terminal M2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal M2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals M2-2 (B) and M2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal M2-7 (DOWN).

| Motor gear rotates clockwise |

- If the result is not as specified, replace the power window regulator motor assembly RH.

CAUTION:

Initialize the power window control system after installing the rear door window regulator assembly.

READ NEXT:

INSTALLATION CAUTION / NOTICE / HINT COMPONENTS (INSTALLATION)

Procedure Part Name Code

1 POWER WINDOW REGULATOR MOTOR ASSEMBLY

85710F

- -

2

REMOVAL CAUTION / NOTICE / HINT COMPONENTS (REMOVAL)

Procedure Part Name Code

1 DECK TRIM SIDE PANEL ASSEMBLY

64740C -

- -

2 ROOF SIDE INNER GAR

SEE MORE:

MONITOR DESCRIPTION DTC P063051 is stored when the Vehicle Identification Number (VIN) is not stored in the ECM or the stored VIN is not accurate.

DTC No. Detection Item

DTC Detection Condition Trouble Area

MIL Note

P063051 VIN Not Programmed

Either of the follo

DESCRIPTION The Variable Valve Timing (VVT) system (for exhaust side) adjusts the exhaust valve timing to improve driveability. The engine oil pressure turns the VVT controller (camshaft timing exhaust gear assembly) to adjust the valve timing.

The cam timing oil control solenoid assembly operates