Toyota Corolla Cross: Indicator Circuit

DESCRIPTION

In accordance with the shift lever position, each shift position indicator light will turn on.

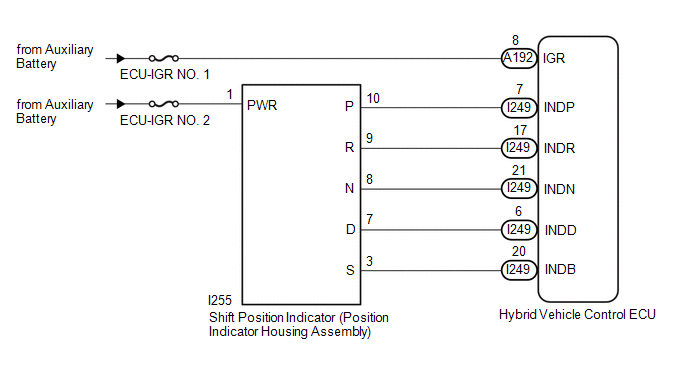

WIRING DIAGRAM

PROCEDURE

|

1. | CHECK SHIFT POSITION INDICATOR |

(a) Turn the ignition switch to ACC.

(b) Check that each shift position indicator light turns on correctly.

|

Result | Proceed to |

|---|---|

|

All shift position indicator lights turn on simultaneously |

A |

| Shift position indicator lights other than corresponding one turn on |

B |

| Corresponding shift position indicator light does not turn on |

C |

| No shift position indicator lights turn on |

D |

(c) Turn the ignition switch off.

| A | .gif) | GO TO STEP 2 |

| C | .gif) | GO TO STEP 4 |

| D | .gif) | GO TO STEP 4 |

|

|

2. | CHECK HARNESS AND CONNECTOR (CHECK FOR SHORT TO GND) |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-7 (INDP) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-17 (INDR) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-21 (INDN) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-6 (INDD) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-20 (INDB) - Body ground and other terminals |

Always | 10 kΩ or higher |

(c) Reconnect the hybrid vehicle control ECU connector.

| OK | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

|

|

3. | CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - SHIFT POSITION INDICATOR (POSITION INDICATOR HOUSING ASSEMBLY)) |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Disconnect the shift position indicator (position indicator housing assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-7 (INDP) or I255-10 (P) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-17 (INDR) or I255-9 (R) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-21 (INDN) or I255-8 (N) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-6 (INDD) or I255-7 (D) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

I249-20 (INDB) or I255-3 (S) - Body ground and other terminals |

Always | 10 kΩ or higher |

(d) Reconnect the shift position indicator (position indicator housing assembly) connector.

(e) Reconnect the hybrid vehicle control ECU connector.

| OK | .gif) | REPLACE POSITION INDICATOR HOUSING ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

4. | CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

(a) Disconnect the shift position indicator connector.

(b) Turn the ignition switch to ACC.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I255-1 (PWR) - Body ground |

Ignition switch ACC |

11 to 14 V |

(d) Turn the ignition switch off.

(e) Reconnect the shift position indicator connector.

| NG | .gif) | REPAIR OR REPLACE POWER SOURCE CIRCUIT |

|

|

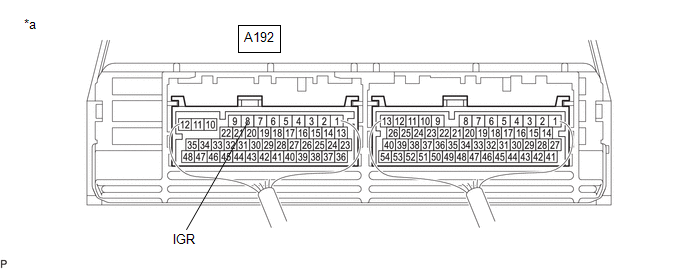

5. | CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL IGR) |

(a) Turn the ignition switch to ACC.

(b) Measure the voltage according to the value(s) in the table below.

|

*a | Component with harness connected (Hybrid Vehicle Control ECU) |

- | - |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A192-8 (IGR) - Body ground |

Ignition switch ACC |

11 to 14 V |

(c) Turn the ignition switch off.

| NG | .gif) | REPAIR OR REPLACE POWER SOURCE CIRCUIT |

|

|

6. | CHECK HARNESS AND CONNECTOR (CHECK FOR OPEN) |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Turn the ignition switch to ACC.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-7 (INDP) - Body ground and other terminals |

Ignition switch ACC |

11 to 14 V |

|

I249-17 (INDR) - Body ground and other terminals |

Ignition switch ACC |

11 to 14 V |

|

I249-21 (INDN) - Body ground and other terminals |

Ignition switch ACC |

11 to 14 V |

|

I249-6 (INDD) - Body ground and other terminals |

Ignition switch ACC |

11 to 14 V |

|

I249-20 (INDB) - Body ground and other terminals |

Ignition switch ACC |

11 to 14 V |

(d) Turn the ignition switch off.

(e) Reconnect the hybrid vehicle control ECU connector.

| OK | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

|

|

7. | CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - SHIFT POSITION INDICATOR (POSITION INDICATOR HOUSING ASSEMBLY)) |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Disconnect the shift position indicator connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-7 (INDP) - I255-10 (P) |

Always | Below 1 Ω |

|

I249-17 (INDR) - I255-9 (R) |

Always | Below 1 Ω |

|

I249-21 (INDN) - I255-8 (N) |

Always | Below 1 Ω |

|

I249-6 (INDD) - I255-7 (D) |

Always | Below 1 Ω |

|

I249-20 (INDB) - I255-3 (S) |

Always | Below 1 Ω |

(d) Reconnect the shift position indicator connector.

(e) Reconnect the hybrid vehicle control ECU connector.

| OK | .gif) | REPLACE POSITION INDICATOR HOUSING ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)