Toyota Corolla Cross: Drive Start Control

DESCRIPTION

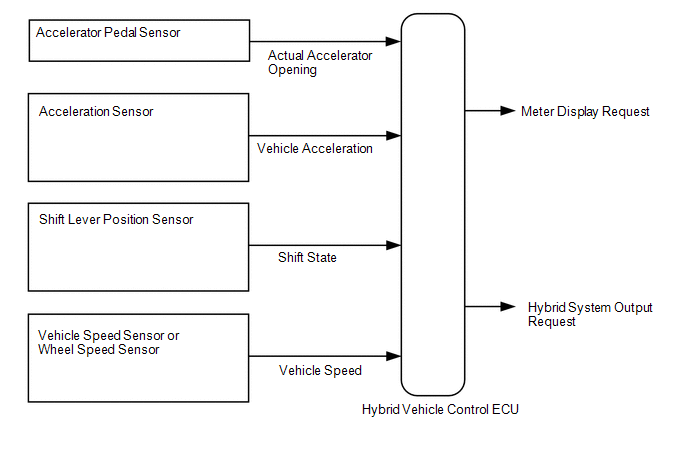

The drive start control is controlled by the hybrid vehicle control ECU.

If the hybrid vehicle control ECU determines that the shift lever and accelerator pedal are operated abnormally, hybrid system output is restricted and, when necessary, a warning is displayed on the combination meter assembly.

CAUTION / NOTICE / HINT

HINT:

Even if the accelerator pedal position is maintained, the hybrid system output may increase when driving uphill and decrease when driving downhill. This is due to drive start control controlling the hybrid system output, and is not a malfunction.

PROCEDURE

|

1. | PAST ACTIVATION CONFIRMATION |

(a) Check if the customer operated the vehicle in a way that would cause the drive start control to operate.

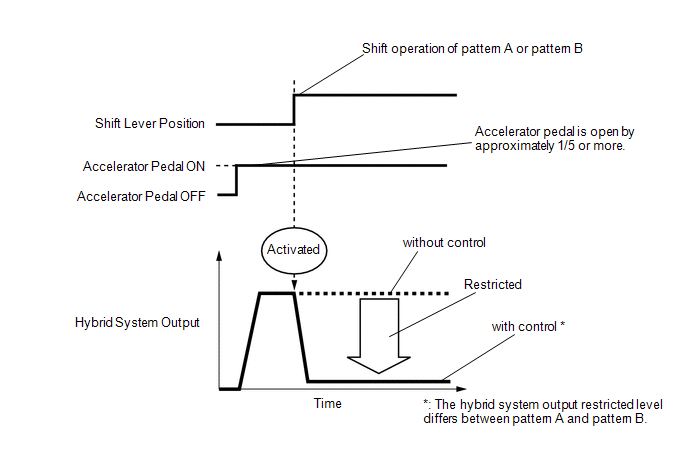

Drive Start Control Activation Conditions Shift control- Activation conditions

- Pattern A (When all of the following conditions are met, control starts.)

- The accelerator pedal is open by approximately 1/5 or more.

- The shift lever is moved from P to (D or S) or R.

- Pattern B (When all of the following conditions are met, control starts.)

- The accelerator pedal is open by approximately 1/5 or more.

- The shift lever is moved from R to (D or S), from (D or S) or N to R.

HINT:

Operation may not be possible in certain situations.

- Items Controlled

- Hybrid system output is restricted.

- Deactivation Conditions

- The accelerator pedal is released.

- The shift lever is in P or N.

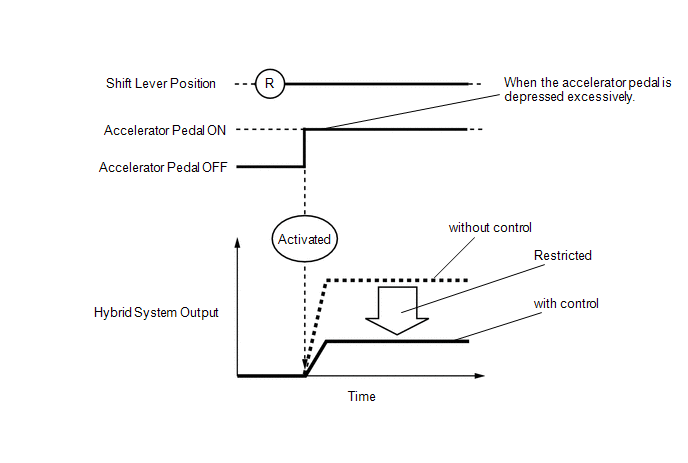

- Activation conditions

- The shift lever is in R.

- The accelerator pedal is depressed excessively.

- Items Controlled

- Hybrid system output is restricted.

- Deactivation Conditions

- The accelerator pedal is released.

- The shift lever is moved to any position other than R.

HINT:

- The hybrid system output restricted level differs between Pattern A, Pattern B and Reverse control.

- During Shift control or Reverse control, hybrid system output is adjusted based on the road gradient.

| Result |

Proceed to |

|---|---|

| Performed |

A |

| Not performed |

B |

| B | .gif) | SYSTEM NORMAL (GO TO PROBLEM SYMPTOM TABLE) |

|

|

2. | CHECK DTC OUTPUT (HEALTH CHECK) |

(a) Check the DTCs.

(b) Turn the ignition switch off.

|

Result | Proceed to |

|---|---|

|

DTCs are not output (Hunting) |

A |

| DTCs are not output (Hesitation/poor acceleration) |

B |

| DTCs are output |

C |

| B | .gif) | GO TO STEP 6 |

| C | .gif) | GO TO DTC CHART |

|

|

3. | READ VALUE USING GTS (FR, FL, RR, RL WHEEL SPEED) |

(a) Read the values displayed on the GTS.

Chassis > Brake/EPB > Data List|

Tester Display |

|---|

|

FR Wheel Speed |

|

FL Wheel Speed |

|

RR Wheel Speed |

|

RL Wheel Speed |

Standard:

|

Tester Display | Condition |

Specified Condition |

|---|---|---|

|

FR Wheel Speed FL Wheel Speed RR Wheel Speed RL Wheel Speed | Vehicle stopped |

0 km/h (0 mph) |

|

Vehicle being driven at constant speed between 16 to 64 km/h (10 to 40 mph) |

No large fluctuations when driving at a constant speed |

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

Data can be captured relatively easily by using the snapshot function in the Data List. Confirm the data after performing the drive test.

(b) Turn the ignition switch off.

| NG | .gif) | INSPECT FRONT OR REAR SPEED SENSOR |

|

|

4. | READ VALUE USING GTS (VEHICLE SPEED) |

(a) Read the value of "Vehicle Speed" displayed on the GTS.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

Vehicle Speed |

Standard:

|

Inspection Condition |

Specified Condition |

|---|---|

|

Vehicle stopped | 0 km/h (0 mph) |

|

Vehicle being driven at a constant speed (16 to 64 km/h (10 to 40 mph)) |

No large fluctuations in displayed speed |

CAUTION:

Perform this road test only in an appropriate safe location, in accordance with all local laws.

HINT:

Data can be captured relatively easily by using the snapshot function in the Data List. Confirm the data after performing the drive test.

(b) Turn the ignition switch off.

| NG | .gif) | INSPECT ELECTRONICALLY CONTROLLED BRAKE SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) |

|

|

5. | READ VALUE USING GTS (FORWARD AND REARWARD G) |

(a) Read the value displayed on the GTS.

Chassis > Brake/EPB > Data List|

Tester Display |

|---|

|

Forward and Rearward G |

Standard:

|

Condition | Specified Condition |

|---|---|

|

During deceleration |

Value changes with vehicle speed |

|

During acceleration |

Value changes with vehicle speed |

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

Data can be captured relatively easily by using the snapshot function in the Data List. Confirm the data after performing the drive test.

(b) Turn the ignition switch off.

| OK | .gif) | SYSTEM NORMAL (GO TO PROBLEM SYMPTOM TABLE) |

| NG | .gif) | INSPECT ELECTRONICALLY CONTROLLED BRAKE SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) |

|

6. | INSPECT SHIFT LEVER POSITION SENSOR |

(a) Inspect the shift lever position sensor.

Click here

.gif)

| Result |

Proceed to |

|---|---|

|

Normal | A |

|

Abnormal | B |

| B | .gif) | REPLACE SHIFT LEVER POSITION SENSOR |

|

|

7. | READ VALUE USING GTS (ACCELERATOR POSITION SENSOR NO. 1 VOLTAGE %, ACCELERATOR POSITION SENSOR NO. 2 VOLTAGE %) |

(a) Read the value displayed on the GTS.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

Accelerator Position Sensor No.1 Voltage % |

|

Accelerator Position Sensor No.2 Voltage % |

OK:

|

Condition | Specified Condition |

|---|---|

|

Accelerator Pedal Released → Depressed |

Values smoothly change following accelerator pedal operation |

(b) Turn the ignition switch off.

| OK | .gif) | SYSTEM NORMAL (GO TO PROBLEM SYMPTOM TABLE) |

| NG | .gif) | REPLACE ACCELERATOR PEDAL(W/SENSOR) ROD ASSEMBLY |

.gif)