Toyota Corolla Cross: DC/DC Converter System Performance (P19E100)

DESCRIPTION

The DC/DC converter converts the voltage from the HV battery to supply power to the vehicle lights, audio system and various ECUs, etc.

At the same time, it performs charging of the auxiliary battery, controlling the output voltage to maintain a specific voltage at the auxiliary battery terminal.

Via CAN communication, the hybrid vehicle control ECU sends stop commands to the DC/DC converter, and receives DC/DC converter Normal/Malfunction status signals.

When an auxiliary charging system malfunction causes DC/DC converter output to stop, and either the auxiliary battery voltage is 11 V or more for 5 seconds or more, or the auxiliary battery voltage is 11 V or less for 0.05 seconds or more, this DTC is stored.

This DTC may also be stored if a malfunction of the inverter cooling system (blockage, inverter water pump malfunction, etc.) or a high-voltage insulation malfunction occurs.

|

DTC No. | Detection Item |

DTC Detection Condition |

Trouble Area | MIL |

Warning Indicate | Note |

|---|---|---|---|---|---|---|

|

P19E100 | DC/DC Converter System Performance |

Any of the following conditions are met:

(1 trip detection logic) |

| Does not come on |

Master Warning: Comes on |

SAE Code: P19E1 |

HINT:

*: If the DC/DC converter is malfunctioning, its operation and charging will be stopped and the auxiliary battery voltage will drop.

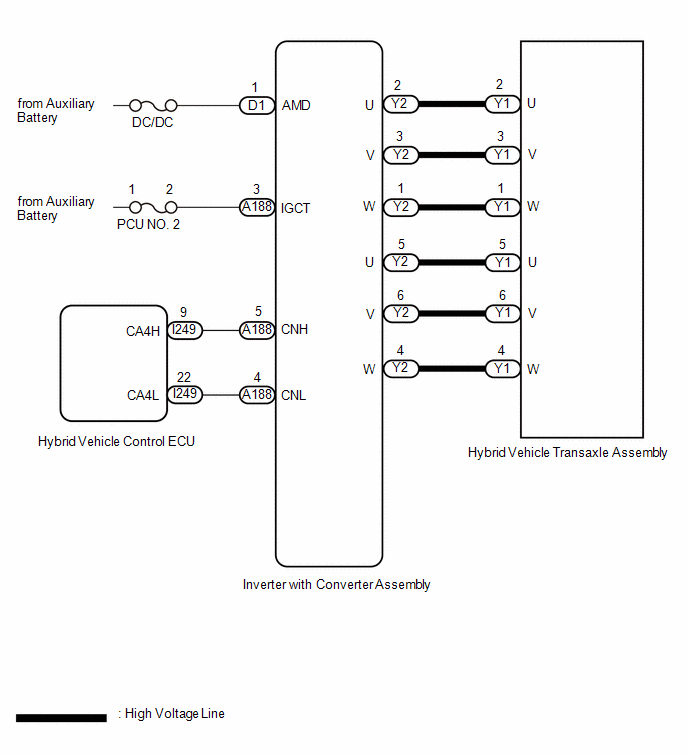

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here .gif)

NOTICE:

- After the ignition switch is turned off, there may be a waiting time before disconnecting the auxiliary negative (-) battery terminal.

Click here

.gif)

- When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

.gif)

HINT:

- After repair, clear the DTCs, turn the ignition switch off and wait for 30 seconds or more and perform the following procedure to confirm that the auxiliary battery low voltage indicated by this DTC has been repaired.

- Wait for 2 minutes with the shift lever in P, the ignition switch ON (READY) and the following conditions met, then confirm that Data List item "BATT Voltage (Hybrid control system)" is between 13.0 and 15.0 V.

(If charging is not performed and the electrical load increases, +B voltage may not be steady and will gradually drop.)

- Headlight switch is in the HI position.

- A/C blower fan switch is in the HI position.

- Window defogger switch is turned on.

- Wait for 2 minutes with the shift lever in P, the ignition switch ON (READY) and the following conditions met, then confirm that Data List item "BATT Voltage (Hybrid control system)" is between 13.0 and 15.0 V.

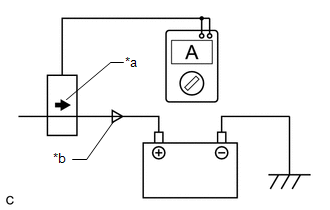

- By performing the following procedure, the DC/DC converter function can be checked.

- Connect the AC/DC 400 A probe to the positive (+) auxiliary battery cable.

- Turn the ignition switch to ON (READY) and leave the vehicle as is until the electric current flowing to the auxiliary battery becomes 10 A or less.

- Turn the ignition switch to ON (READY) and turn the headlight switch and A/C blower fan switch to the HI position and the window defogger on.

- Confirm that the current drawn from the auxiliary battery is 0 A or lower and the auxiliary battery voltage is between 13.0 and 15.0 V.

- Connect the AC/DC 400 A probe to the positive (+) auxiliary battery cable.

- This DTC may be also stored when a part other than the DC/DC converter is malfunctioning or depending on user operation.

- If this vehicle is used to jump start another vehicle with a discharged battery, a fuse may blow due to overcurrent or the DC/DC converter self-protection may be activated. Also, if this vehicle is jump started by a vehicle with a 24 V battery, the same malfunction may occur and this DTC may be stored. (The suspended DC/DC converter control will return to normal by clearing the DTCs and turning the ignition switch off.)

- Check whether high electrical load equipment such as a high-capacitance audio device or electric kettle is used in the vehicle. (A fuse of the auxiliary battery may be blown due to overcurrent.)

- If the DC/DC converter is malfunctioning, the auxiliary battery cannot be charged. Therefore, once the ignition switch is turned off, it may be impossible to turn it to ON (READY) again if the auxiliary battery is completely discharged. In this case, charge the auxiliary battery. Be careful as charging is not performed during the inspection.

- If the ignition switch turns off immediately after it is turned to ON (READY), the auxiliary battery voltage may be low. Charge the auxiliary battery.

- P19E100 may be output as a result of the malfunction indicated by the DTCs in table below.

- The chart above is listed in inspection order of priority.

- Check DTCs that are output at the same time by following the listed order. (The main cause of the malfunction can be determined without performing unnecessary inspections.) Table 1

Table 2Malfunction Content

System

Relevant DTC

Insulation Malfunction

Hybrid control system

P1C7C49

Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure

P1C7D49

Hybrid/EV Battery Voltage System Isolation (Hybrid/EV Battery Area) Internal Electronic Failure

P1C7E49

Hybrid/EV Battery Voltage System Isolation (Transaxle Area) Internal Electronic Failure

P1C7F49

Hybrid/EV Battery Voltage System Isolation (Direct Current Area) Internal Electronic Failure

P1C8049

Hybrid/EV Battery Voltage System Isolation (Rear Motor Area) Internal Electronic Failure

High Voltage Circuit Malfunction

Hybrid control system

P0AA649

Hybrid/EV Battery Voltage System Isolation Internal Electronic Failure

P0AD911

Hybrid/EV Battery Positive Contactor Circuit Short to Ground

P0ADD11

Hybrid/EV Battery Negative Contactor Circuit Short to Ground

P1C8449

High Voltage Power Resource Circuit Short during Ready ON

P300449

High Voltage Power Resource Circuit Short during Pre-Charge

Malfunction Content

System

Relevant DTC

System malfunction

Hybrid control system

U01BD87

Lost Communication with DC/DC Converter Control Module "C"

P0A9300

Inverter "A" Cooling System Performance

P0C7396

Motor Electronics Coolant Pump "A" Component Internal Failure

P314A31

Motor Electronics Coolant Pump "A" No Signal

Motor generator control system

P0E5717

DC/DC Converter Voltage Sensor "A" (VL) Circuit Voltage Above Threshold

PROCEDURE

|

1. | CHECK FUSE (DC/DC) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

(b) Remove the DC/DC fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

DC/DC fuse | Always |

Below 1 Ω |

(d) Install the DC/DC fuse.

(e) Connect the cable to the negative (-) auxiliary battery terminal.

| NG | .gif) | GO TO STEP 15 |

|

|

2. | CHECK CONNECTOR CONNECTION CONDITION (HYBRID VEHICLE CONTROL ECU CONNECTOR) |

Click here .gif)

| NG | .gif) | CONNECT SECURELY |

|

|

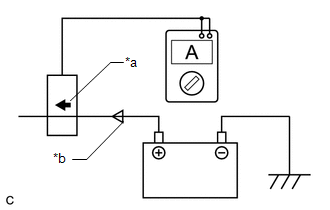

3. | CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Check the connection condition of the low voltage connectors of the inverter with converter assembly and the contact pressure of each terminal. Check the terminals for deformation, and the connector for water and foreign matter.

Click here .gif)

NOTICE:

Before disconnecting the connector, confirm that it is properly connected by checking that the claws of the lock levers are engaged and that the connector cannot be pulled off.

OK:

- The connector is connected securely.

- The terminals are not deformed and are connected securely.

- No water or foreign matter in the connector.

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (The connector is not connected securely.) |

B |

| NG (The terminals are not making secure contact or are deformed, or water or foreign matter exists in the connector.) |

C |

HINT:

When connecting the connector, connect it with the lock levers raised. Rotate each lock lever downward and make sure that the connector is securely connected. When a lock lever is fully lowered, a click will be heard as its claw engages. After the click is heard, pull up on the connector to confirm that it is securely connected.

| B | .gif) | CONNECT SECURELY |

| C | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. | CHECK FUSE (PCU NO. 2) |

(a) Remove the PCU NO. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

PCU NO. 2 fuse | Always |

Below 1 Ω |

| NG | .gif) | REPLACE FUSE (PCU NO. 2) |

|

|

5. | CHECK HARNESS AND CONNECTOR (DC/DC CONVERTER POWER SOURCE CIRCUIT) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the inverter with converter assembly connector.

(c) Connect the cable to the negative (-) auxiliary battery terminal.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A188-3 (IGCT) - Body ground |

Ignition switch ON |

Same as auxiliary battery voltage |

NOTICE:

Turning the ignition switch to ON with the service plug grip removed causes other DTCs to be stored. Clear the DTCs after performing this inspection.

(f) Turn the ignition switch off.

(g) Disconnect the cable from the negative (-) auxiliary battery terminal.

(h) Reconnect the inverter with converter assembly connector.

| NG | .gif) | REPLACE MALFUNCTIONING PARTS |

|

|

6. | CHECK AMD TERMINAL VOLTAGE |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Connect the cable to the negative (-) auxiliary battery terminal.

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Disconnect the cable from the negative (-) auxiliary battery terminal.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

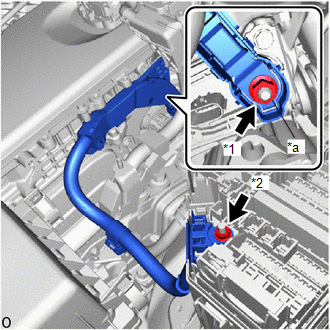

7. | CHECK AMD TERMINAL CONNECTION CONDITION |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

| (b) Check that the nuts for the AMD terminal are tightened to the specified torque, the AMD terminal is connected securely, and there are no contact problems. Result:

|

| ||||||||||||||||||

| B | .gif) | CONNECT SECURELY |

| C | .gif) | REPLACE MALFUNCTIONING PARTS |

|

|

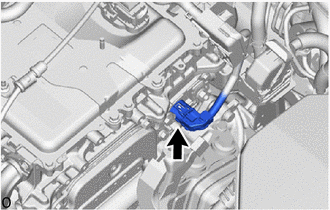

8. | CHECK GROUND WIRE CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY) |

Click here .gif)

OK:

The ground wire is securely installed.

| NG | .gif) | CONNECT SECURELY |

|

|

9. | CHECK HARNESS AND CONNECTOR (HYBRID VEHICLE CONTROL ECU - INVERTER WITH CONVERTER ASSEMBLY) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the inverter with converter assembly connector.

(c) Disconnect the hybrid vehicle control ECU connector.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A188-5 (CNH) - I249-9 (CA4H) |

Ignition switch off |

Below 1 Ω |

|

A188-4 (CNL) - I249-22 (CA4L) |

Ignition switch off |

Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A188-5 (CNH) or I249-9 (CA4H) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

|

A188-4 (CNL) or I249-22 (CA4L) - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

(e) Reconnect the hybrid vehicle control ECU connector.

(f) Reconnect the inverter with converter assembly connector.

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

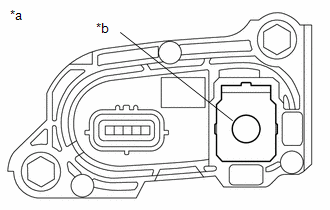

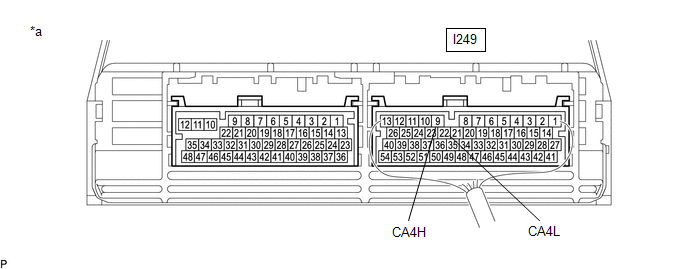

10. | INSPECT HYBRID VEHICLE CONTROL ECU |

(a) Disconnect the hybrid vehicle control ECU connector.

(b) Measure the resistance according to the value(s) in the table below.

|

*a | Component without harness connected (Hybrid Vehicle Control ECU) |

- | - |

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I249-9 (CA4H) - I249-22 (CA4L) |

Ignition switch off |

80 to 170 Ω |

(c) Reconnect the hybrid vehicle control ECU connector.

| NG | .gif) | REPLACE HYBRID VEHICLE CONTROL ECU |

|

|

11. | CHECK COOLING SYSTEM |

Click here .gif)

|

|

12. | CHECK DC/DC CONVERTER FUNCTION |

HINT:

The current at the AMD terminal cannot be measured directly because of space limitations. Measure the current flowing at the auxiliary battery instead.

(a) Connect the AC/DC 400 A probe of the tester to the positive (+) auxiliary battery cable.

(b) Install the service plug grip.

(c) Connect the cable to the negative (-) auxiliary battery terminal.

| (d) Turn the ignition switch to ON (READY) and leave the vehicle as it is until the electric current flowing to the auxiliary battery becomes 10 A or less. HINT: If the ignition switch turns off immediately after it is turned to ON (READY), auxiliary battery voltage may be low. Recharge the auxiliary battery and perform this procedure again. |

|

| (e) Measure the current flowing from the auxiliary battery with the ignition switch ON (READY), the headlight position switch and blower motor switch in the HI position, and the rear window defogger turned on. Standard Current:

|

|

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Item | Condition |

Specified Condition |

|---|---|---|

|

Auxiliary battery voltage |

Ignition switch ON (READY) (The headlight position switch and blower motor switch are in the HI position, and the rear window defogger is turned on.) |

12.5 to 15 V |

(g) Turn the ignition switch off.

| NG | .gif) | GO TO STEP 14 |

|

|

13. | CHECK DTC OUTPUT (HYBRID CONTROL) |

(a) Check for DTCs.

Powertrain > Hybrid Control > Trouble Codes| Result |

Proceed to |

|---|---|

| P19E100 is output. |

A |

| P19E100 is not output. |

B |

HINT:

As the DTC detection conditions include decreased auxiliary battery voltage, if the DTC is not input again, when the auxiliary battery is charged it can be judged that the vehicle has returned to normal.

(b) Turn the ignition switch off.

| A | .gif) | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

| B | .gif) | RECHARGE AUXILIARY BATTERY |

|

14. | CHECK HIGH VOLTAGE INSULATION |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

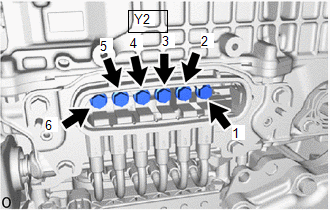

(b) Remove the inverter cover from the inverter with converter assembly.

| (c) Using a megohmmeter set to 500 V, measure the insulation resistance according to the value(s) in the table below. NOTICE: Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected. Standard Resistance:

HINT: Perform this inspection while the motor cable is connected. |

|

(d) Install the inverter cover to the inverter with converter assembly.

| OK | .gif) | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

| NG | .gif) | GO TO STEP 17 |

|

15. | CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - NO. 1 ENGINE ROOM RELAY BLOCK AND NO. 1 JUNCTION BLOCK ASSEMBLY) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the cable from the negative (-) auxiliary battery terminal.

(c) Disconnect the engine wire from the AMD terminal connector (inverter with converter assembly side and No. 1 engine room relay block and No. 1 junction block assembly side).

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

D1-1 (AMD) or 2D-1 - Body ground and other terminals |

Ignition switch off |

10 kΩ or higher |

(e) Reconnect the AMD terminal connector.

(f) Connect the cable to the negative (-) auxiliary battery terminal.

| NG | .gif) | GO TO STEP 20 |

|

|

16. | CHECK INVERTER WITH CONVERTER ASSEMBLY (AMD TERMINAL) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the engine wire from the inverter with converter assembly (AMD terminal connector).

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(d) Reconnect the engine wire.

| OK | .gif) | REPLACE FUSE (DC/DC) |

| NG | .gif) | GO TO STEP 19 |

|

17. | CHECK GENERATOR HIGH-VOLTAGE CIRCUIT |

Click here .gif)

|

|

18. | CHECK MOTOR HIGH-VOLTAGE CIRCUIT |

Click here .gif)

HINT:

If the "Motor High-voltage Circuit" inspection results are normal, perform the next step.

| NEXT | .gif) | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

|

19. | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

Click here .gif)

| NEXT | .gif) | REPLACE FUSE (DC/DC) |

|

20. | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| NEXT | .gif) | REPLACE FUSE (DC/DC) |

.gif)

.png)