Toyota Corolla Cross: Brake Fluid (for Gasoline Model)

Components

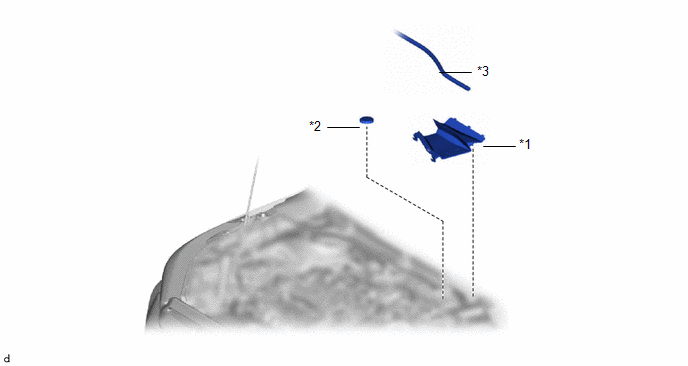

COMPONENTS

ILLUSTRATION

|

*1 |

CENTER COWL TOP VENTILATOR LOUVER |

*2 |

BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY |

|

*3 |

HOOD TO COWL TOP SEAL |

- |

- |

ILLUSTRATION

|

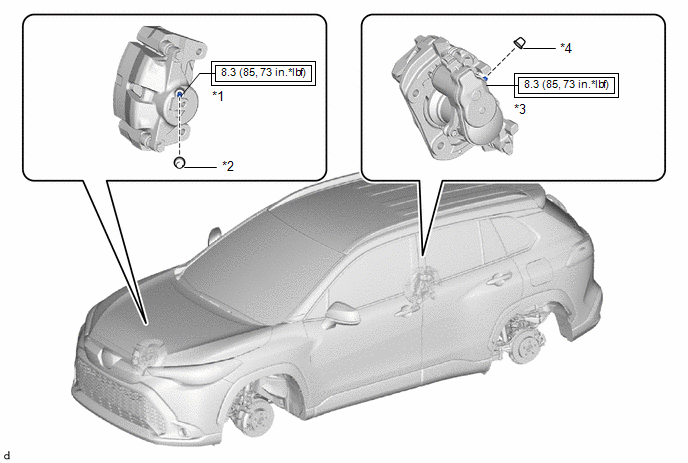

*1 |

FRONT DISC BRAKE BLEEDER PLUG |

*2 |

FRONT DISC BRAKE BLEEDER PLUG CAP |

|

*3 |

REAR DISC BRAKE BLEEDER PLUG |

*4 |

REAR DISC BRAKE BLEEDER PLUG CAP |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

- |

- |

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

NOTICE:

- Move the shift lever to P and apply the parking brake before replacing the brake fluid.

- Add brake fluid to keep the level between the MIN and MAX lines of the reservoir while replacing the brake fluid.

- If brake fluid leaks onto any painted surface, immediately wash it off.

HINT:

If any work is performed on the brake system or if air in the brake lines is suspected, bleed the air from the brake system.

PROCEDURE

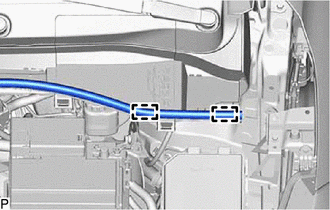

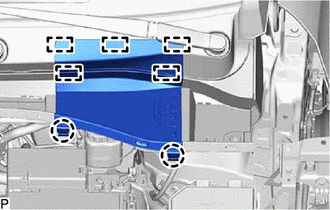

1. REMOVE CENTER COWL TOP VENTILATOR LOUVER

|

(a) Disengage the 2 hooks and separate the hood to cowl top seal from the cowl top ventilator louver sub-assembly. |

|

|

(b) Disengage the 2 claws and 5 guides to remove the center cowl top ventilator louver from the cowl top ventilator louver sub-assembly. |

|

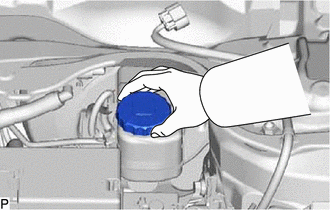

2. REMOVE BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY

|

(a) Remove the brake master cylinder reservoir filler cap assembly. |

|

3. FILL RESERVOIR WITH BRAKE FLUID

(a) Fill the reservoir with brake fluid.

Brake Fluid:

SAE J1703 or FMVSS No. 116 DOT3

SAE J1704 or FMVSS No. 116 DOT4

NOTICE:

- Make sure that there is sufficient brake fluid in the reservoir.

- Do not remove the filter from the brake master cylinder reservoir and be sure to fill the brake master cylinder reservoir with new brake fluid to avoid any potential contamination of the brake system. Contamination, for example by dirt particles or mineral oil, could lead to functional brake problems.

4. REPLACE BRAKE FLUID

(a) Remove the bleeder plug cap.

(b) Connect a vinyl tube to the bleeder plug.

(c) Depress the brake pedal several times, and then loosen the bleeder plug with the pedal depressed.*1

(d) When fluid stops coming out, tighten the bleeder plug and release the brake pedal.*2

(e) Repeat steps *1 and *2 until new brake fluid comes out.

(f) Tighten the bleeder plug completely.

Torque:

8.3 N·m {85 kgf·cm, 73 in·lbf}

(g) Install the bleeder plug cap.

(h) Repeat the above steps to replace the brake fluid of the brake lines for each wheel.

5. INSPECT FOR BRAKE FLUID LEAK

6. INSPECT BRAKE FLUID LEVEL IN RESERVOIR

Click here .gif)

7. INSTALL BRAKE MASTER CYLINDER RESERVOIR FILLER CAP ASSEMBLY

(a) Install the brake master cylinder reservoir filler cap assembly.

8. INSTALL CENTER COWL TOP VENTILATOR LOUVER

(a) Engage the 5 guides and 2 claws to install the center cowl top ventilator louver to the cowl top ventilator louver sub-assembly.

(b) Engage the 2 hooks to install the hood to cowl top seal to the cowl top ventilator louver sub-assembly.