Toyota Corolla Cross: Differential Oil

Components

COMPONENTS

ILLUSTRATION

|

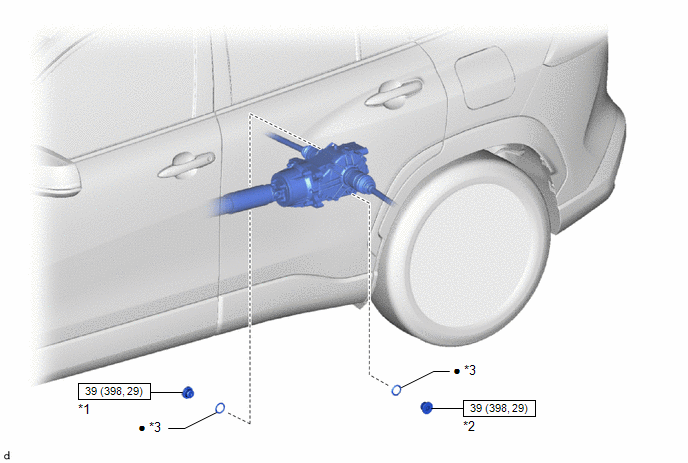

*1 |

REAR DIFFERENTIAL FILLER PLUG |

*2 |

REAR DIFFERENTIAL DRAIN PLUG |

|

*3 |

GASKET |

- |

- |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● |

Non-reusable part |

Replacement

REPLACEMENT

PROCEDURE

1. DRAIN DIFFERENTIAL OIL

(a) Stop the vehicle on a level surface.

|

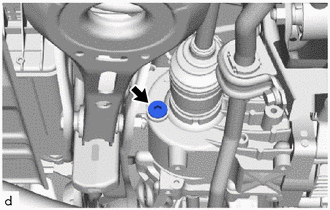

(b) Using a 10 mm hexagon socket wrench, remove the rear differential filler plug and gasket. |

|

|

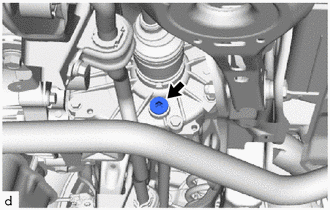

(c) Using a 10 mm hexagon socket wrench, remove the rear differential drain plug and gasket and drain the differential oil. |

|

(d) Using a 10 mm hexagon socket wrench, install a new gasket and the rear differential drain plug.

Torque:

39 N·m {398 kgf·cm, 29 ft·lbf}

2. ADD DIFFERENTIAL OIL

(a) Add differential oil.

Standard oil type and viscosity:

Toyota Genuine Differential Gear Oil LT 75W-85 GL-5 or equivalent

Standard oil capacity:

0.50 liters (0.52 US qts, 0.43 Imp. qts)

|

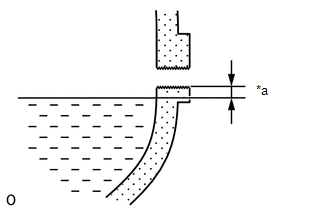

(b) Pour oil so that the oil level is between 0 to 5 mm (0 to 0.197 in.) from the bottom lip of the rear differential filler plug hole. NOTICE:

|

|

(c) Wait approximately 5 minutes and check that the oil level has not changed.

|

(d) Using a 10 mm hexagon socket wrench, install a new gasket and the rear differential filler plug. Torque: 39 N·m {398 kgf·cm, 29 ft·lbf} |

|

(e) Drive the vehicle and check the oil level again. If necessary, add differential oil.

3. INSPECT FOR DIFFERENTIAL OIL LEAK

(a) Make sure that there are no differential oil leaks from the area that was worked on.