Toyota Corolla Cross: After Engine Stops due to Stop and Start System, Engine does not Restart

DESCRIPTION

- This is the troubleshooting procedure for situations where the engine does not restart after having been stopped by the stop and start system.

- For information on stop and start control, refer to the system description.

Click here

.gif)

CAUTION / NOTICE / HINT

PRECAUTIONS WHEN THE ENGINE STOP AND START ECU AND THE STARTER ASSEMBLY ARE REPLACED

NOTICE:

- When the engine stop and start ECU is replaced, it is necessary to read the number of starter operations before replacement and store this number in the new engine stop and start ECU after replacement, and to perform external backup boost converter (eco run vehicle converter assembly) existence learning. Moreover, initialization/learning of the air conditioning information is also required (for Mexico Models).

Click here

.gif)

- When the starter assembly is replaced, the number of starter operations stored in the engine stop and start ECU must be reset.

Click here

.gif)

- When the starter assembly is replaced, "ST relay" must be also replaced.

- Inspect the fuses for circuits related to this system before performing the following procedure.

PRECAUTIONS WHEN AUXILIARY BATTERY IS DISCHARGED AFTER LEAVING VEHICLE FOR A LONG TIME

HINT:

If the vehicle has not been used for a long time, the auxiliary battery charge may be low and stop and start control operation may be prohibited. After recharging the auxiliary battery until the charging current decreases to 5 A or below, if the integrated current value still does not increase to the threshold value*1 or above, initialize the integrated current value*2 and drive the vehicle approximately 5 to 40 minutes until stop and start control operates.

- *1: For information about the integrated current threshold value, refer to the system description.

Click here

.gif)

- *2: Use the GTS to perform Integrated Current Value Initialization.

Click here

.gif)

PRECAUTIONS WHEN CONNECTING/DISCONNECTING CABLE TO/FROM NEGATIVE AUXILIARY BATTERY TERMINAL

HINT:

- If the cable is disconnected from the auxiliary battery terminal, stop and start control is prohibited until refresh charge is completed. In this case, let the vehicle idle to complete the refresh charge. The refresh charge is complete when the Data List item Status of Battery Charge Control changes from "Refresh Charge Mode". (Usually, by idling the engine for 5 to 60 minutes with the auxiliary battery fluid temperature at 11°C (52°F) or higher, the refresh charge will be completed.)

- If the GTS is not available and the Data List item Status of Battery Charge Control cannot be checked, charge the auxiliary battery by idling the engine for approximately 5 to 60 minutes or driving the vehicle, and then drive the vehicle and check that stop and start control operates. If the engine is started with the hood open, the system determines that a jump start has occurred. Therefore, make sure that the hood is closed before starting the engine and driving the vehicle.

- After the refresh charge completes, turn the ignition switch off, wait for at least 30 seconds, and then start the engine again. If the vehicle enters refresh charge mode again while the engine is idling, the initial refresh charge did not properly complete, so wait for the refresh charge to complete.

- If power is not supplied to the audio and visual system when the ignition switch is turned to ON for the first time after the auxiliary battery has been reconnected, DTC P323A19 will be stored. Perform either of the following operations:

- Turn the ignition switch from ON to off twice.

- After turning the ignition switch from ON to off, clear the DTCs.

- If power is not supplied to the audio and visual system when the ignition switch is turned to ON for the first time after the auxiliary battery has been reconnected, DTC P323A19 will be stored. Perform either of the following operations:

IF THE ENGINE FAILS TO RESTART FROM IDLING STOP

NOTICE:

If the engine fails to restart when stopped by stop and start control, the brake actuator may be activated. Brake actuator activation conditions:- When the engine fails to restart when stopped by stop and start control.

- When the brake booster vacuum is insufficient.

- When the vehicle speed is 3 km/h (2 mph) or more and the brake pedal is depressed*.

- *: When the engine is not running.

HINT:

- When the engine fails to restart when stopped by stop and start control and the brake booster vacuum is insufficient, the brake actuator is activated to ensure the braking force. When the brake actuator is activated, sound and vibration may be generated. This is not due to malfunction of the stop and start system or the vehicle.

PRECAUTIONS FOR FOUR-WHEEL TOWING

Do not tow the vehicle with all 4 wheels on the ground.

NOTICE:

- Towing the vehicle with all 4 wheels on the ground may have a detrimental effect on the stop and start system, and could lead to damage.

HINT:

If it is absolutely necessary to tow the vehicle with all 4 wheels on the ground, before towing first turn the ignition switch off. Then, turn the ignition switch to ON without starting the engine, and tow the vehicle.

PRECAUTIONS WHEN REPLACING ECM

NOTICE:

When the ECM is replaced on a vehicle with a non-specified auxiliary battery, it is necessary to perform auxiliary battery type switching.

Click here .gif)

PROCEDURE

| 1. |

CHECK VEHICLE CONTROL HISTORY (RoB) (ENGINE STALL HISTORY DURING STOP&START (HOOD OPEN)) |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

| Result |

Proceed to |

|---|---|

| Vehicle control history (RoB) item "Engine Stall History during Stop&Start (Hood Open)" stored |

A |

| Vehicle control history (RoB) item "Engine Stall History during Stop&Start (Hood Open)" not stored |

B |

| B |

.gif) | GO TO STEP 3 |

|

| 2. |

CHECK VEHICLE CONDITION (ENGINE HOOD CONDITION) |

(a) Check the condition of the engine hood.

Check with the driver to confirm whether or not the engine hood was opened during stop and start control.

| Result |

Proceed to |

|---|---|

| Engine hood was not opened during stop and start control |

A |

| Engine hood was opened during stop and start control |

B |

| A |

.gif) | GO TO ENGINE HOOD COURTESY SWITCH CIRCUIT |

| B |

.gif) | ENGINE STALL DUE TO ENGINE HOOD BEING OPENED DURING STOP AND START CONTROL EXPLAIN THAT ENGINE RESTART BECOMES PROHIBITED |

| 3. |

CUSTOMER PROBLEM ANALYSIS AND SYMPTOM CONFIRMATION |

(a) Consult with the customer to determine if they performed operations that could result in an AT engine stall.

HINT:

(ex.) Heavy load, frequent shifts, etc.

| Result |

Proceed to |

|---|---|

| Driver operations that could cause engine stall were performed |

A |

| None of the above conditions are met |

B |

| A |

.gif) | ENGINE STALL DUE TO DRIVER OPERATION |

|

| 4. |

CHECK DTC OUTPUT |

(a) Following the instructions on the GTS screen, check for SFI system DTCs.

| Result |

Proceed to | |

|---|---|---|

| "SFI system poor startability DTCs/RoBs not output", but "SFI system poor startability related/connected DTCs/RoBs are output". HINT:

| A | |

|

None of the above conditions are met |

| B |

| C | |

| D | |

| A |

.gif) | GO TO SFI SYSTEM (RoB CHART) DIAGNOSTIC TROUBLE CODE: Click here VEHICLE CONTROL HISTORY (RoB): Click here

|

| B |

.gif) | GO TO SMART KEY SYSTEM (START FUNCTION) (ENGINE DOES NOT START) |

| C |

.gif) | INSPECT STARTER SYSTEM (a) Inspect auxiliary battery Click here

(b) Inspect starter system Click here

|

|

| 5. |

STOP AND START SYSTEM OPERATION CHECK |

(a) Perform an operation check of the stop and start system to confirm what kind of operations result in the engine failing to restart after it has been stopped by the stop and start system.

Click here .gif)

| Result |

Proceed to |

|---|---|

| While vehicle is stopped with the engine stopped by idling stop, the engine cannot restart when attempting to drive forward. |

A |

| During idling stop, an operation that should restart the engine (brake off, shift operation, etc.) is performed, but there is no response to the start request (refer to Data List). |

B |

| B |

.gif) | IDENTIFY START REQUEST LOCATION (a) Check the Data List items for countermeasures, and inspect the possible causes of engine start requests not being issued. HINT: Depending on vehicle, some items may not be displayed. Engine Start Request (Brake Release):

|

|

| 6. |

CHECK VEHICLE (FAILURE TO RESTART FROM STOP AND START) |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the data from the time of control.

(c) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

| Result |

Proceed to |

|---|---|

| NO is displayed for Engine Start Fail in the vehicle control history (RoB) |

A |

| Yes is displayed for Engine Start Fail in the vehicle control history (RoB) |

B |

| A |

.gif) | GO TO SFI SYSTEM (RoB CHART) DIAGNOSTIC TROUBLE CODE CHART: Click here

VEHICLE CONTROL HISTORY (RoB): Click here

|

|

| 7. |

CHECK VEHICLE CONTROL HISTORY (RoB) AND PROBLEM SYMPTOMS |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the data from the time of control.

(c) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

| Result |

Proceed to |

|---|---|

| All recorded sections Starter Motor = OFF, and all recorded sections Engine Speed = 0 rpm HINT: It is possible that the starter drive command is not being sent from the engine stop and start ECU. |

A |

| Starter Motor = ON for any sections, and all recorded sections Engine Speed = 0 rpm HINT: It is possible that the drive command is being sent from the engine stop and start ECU but the starter itself is not moving. |

B |

| Engine Speed > 0 rpm for any sections HINT: It is possible that cranking was achieved but the engine stopped. |

C |

| A |

.gif) | REPLACE ENGINE STOP AND START ECU HINT: It is possible that there is a malfunction of the starter drive circuit inside the stop and start ECU. |

| C |

.gif) | GO TO STEP 12 |

|

| 8. |

CHECK VEHICLE CONTROL HISTORY (RoB) AND PROBLEM SYMPTOMS |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the data from the time of control.

(c) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

| Result |

Proceed to |

|---|---|

| Cranking Time is 1.5 seconds or more HINT: It is possible that there is an external malfunction outside of the stop and start ECU (drive circuit). |

A |

| Cranking Time is less than 1.5 seconds HINT: It is possible that there is a malfunction in the stop and start ECU (drive circuit). |

B |

| B |

.gif) | REPLACE ENGINE STOP AND START ECU |

|

| 9. |

CHECK ENGINE STOP AND START ECU (+B VOLTAGE) |

(a) Disconnect the A169 engine stop and start ECU connector.

(b) Turn the ignition switch to ON.

(c) Turn off any electrical loads.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Switch Condition |

Specified Condition |

|---|---|---|

|

A169-1 (+B) - Body ground |

Ignition switch ON | 11 V or higher |

| NG | .gif) | GO TO STEP 11 |

|

| 10. |

CHECK VEHICLE CONTROL HISTORY (RoB) (BATTERY VOLTAGE) |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Check the value of Battery Voltage.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

- Depending on RoB detection timing, the minimum voltage from the previous startup will be stored for the Minimum Voltage (Cranking) and the Minimum Voltage (Starter Solenoid Engagement). For the auxiliary battery condition at the start of the current driving cycle, see Battery Voltage.

- When the value is 20 V, the value is being calculated.

| Result |

Proceed to |

|---|---|

| Battery Voltage is 8.92 V or more |

A |

| Battery Voltage is less than 8.92 V |

B |

| A |

.gif) | INSPECT STARTER SYSTEM |

|

| 11. |

INSPECT AUXILIARY BATTERY |

(a) Measure the voltage of the auxiliary battery.

Standard Voltage:

11 to 14 V

| OK | .gif) | INSPECT STARTER SYSTEM |

| NG | .gif) | REPLACE AUXILIARY BATTERY |

| 12. |

CHECK VEHICLE CONTROL HISTORY (RoB) (CRANKING TIME AND STARTER OFF PERMISSION HISTORY (ECM)) |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the "Cranking Time" and "Starter OFF Permission History (ECM)" data from the time of control.

(c) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

|

Result | Proceed to | |

|---|---|---|

|

Cranking Time is less than 1.5 seconds |

Starter OFF Permission History (ECM) is ON HINT: It is possible that the ECM made a judgment of complete combustion and the ECM then stopped the starter. |

A |

| Starter OFF Permission History (ECM) is OFF HINT: It is possible that the engine stop and start ECU made a judgment of complete combustion and the engine stop and start ECU then stopped the starter. |

B | |

| Cranking Time is 1.5 seconds or more HINT: It is possible that the stop and start ECU did not stop the starter. |

- | C |

| A |

.gif) | SFI SYSTEM (POOR STARTABILITY) HINT: Check whether the speed value of the ECM is not higher than that of the original NE. |

| C |

.gif) | GO TO STEP 17 |

|

| 13. |

READ VALUE USING GTS (ENGINE SPEED) |

(a) In accordance with the display on the GTS, read the Data List.

Powertrain > Stop and Start > Data List|

Tester Display |

|---|

| Engine Speed (ECM) |

|

Engine Speed |

(b) Compare the Data List items displayed on the GTS.

|

Result | Proceed to |

|---|---|

|

Engine Speed > Engine Speed (ECM) + 100 rpm |

A |

| None of the above conditions are met |

B |

| B |

.gif) | GO TO STEP 16 |

|

| 14. |

CHECK DATA POINTS (ENGINE SPEED AND ENGINE SPEED (ECM)) |

(a) Using the GTS, check Vehicle Control History (RoB).

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the data from the time of control.

(c) Check the data points in the data that was output.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

|

Result | Proceed to |

|---|---|

|

For each and all of the data points, Engine Speed > Engine Speed (ECM) + 100 rpm |

A |

| None of the above conditions are met |

B |

| A |

.gif) | READ VALUE USING GTS (ENGINE SPEED) |

|

| 15. |

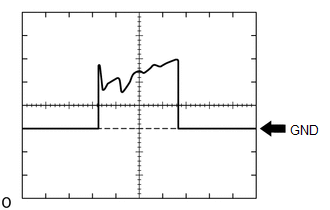

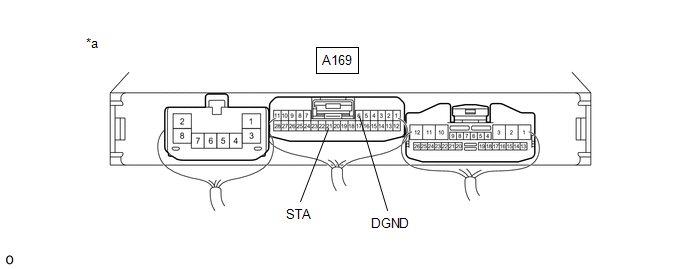

CHECK ENGINE STOP AND START ECU (STA SIGNAL) |

|

*a | Component with harness connected (Engine Stop and Start ECU) |

- | - |

(a) Using the GTS, perform Active Test.

Powertrain > Stop and Start > Active Test|

Tester Display |

|---|

| Starter Motor Drive Magnet Switch(Hood Close) |

(b) Measure the voltage according to the value(s) in the table below.

Click here

.gif)

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - A169-6 (DGND) |

Performing Active Test, while cranking. |

6 to 14 V |

|

A169-21 (STA) - A169-6 (DGND) |

Performing Active Test, while cranking. |

6 to 14 V |

| (c) Using an oscilloscope, measure the waveform immediately after starting.

OK: Voltage and waveform both normal |

|

| OK | .gif) | INSPECT ENGINE (PRE-IGNITION, SFI SYSTEM, POOR STARTABILITY) |

| NG | .gif) | REPLACE ENGINE STOP AND START ECU |

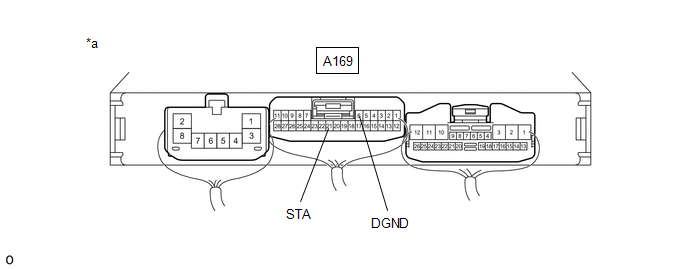

| 16. |

CHECK ENGINE STOP AND START ECU (STA SIGNAL) |

|

*a | Component with harness connected (Engine Stop and Start ECU) |

- | - |

(a) Using the GTS, perform Active Test.

Powertrain > Stop and Start > Active Test|

Tester Display |

|---|

| Starter Motor Drive Magnet Switch(Hood Close) |

(b) Measure the voltage according to the value(s) in the table below.

Click here

.gif)

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - A169-6 (DGND) |

Performing Active Test, while cranking. |

6 to 14 V |

|

A169-21 (STA) - A169-6 (DGND) |

Performing Active Test, while cranking. |

6 to 14 V |

| (c) Using an oscilloscope, measure the waveform immediately after starting.

OK: Voltage and waveform both normal |

|

| OK | .gif) | INSPECT ENGINE (PRE-IGNITION, SFI SYSTEM, POOR STARTABILITY) |

| NG | .gif) | REPLACE ENGINE STOP AND START ECU |

| 17. |

CHECK DATA POINTS (ENGINE SPEED) |

(a) Select a vehicle control history (RoB) item to display the data from the time of control.

(b) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

|

Result | Proceed to |

|---|---|

|

When Starter Motor is ON, there is even 1 point at which Engine Speed < 300 rpm |

A |

| None of the above conditions are met |

B |

| A |

.gif) | INSPECT STARTER SYSTEM |

|

| 18. |

CHECK OPERATION |

(a) Check how long it took the engine to stall after turning the starter off.

|

Result | Proceed to |

|---|---|

|

After starter turned off, engine immediately stalls. HINT: Engine stalls within 2 seconds. |

A |

| After starter turned off, engine stalls after a time. |

B |

| A |

.gif) | GO TO SFI SYSTEM (ENGINE DIFFICULT TO START) |

| B |

.gif) | GO TO SFI SYSTEM (ENGINE STALLS) |

.gif)