Toyota Corolla Cross: Starter Signal Circuit

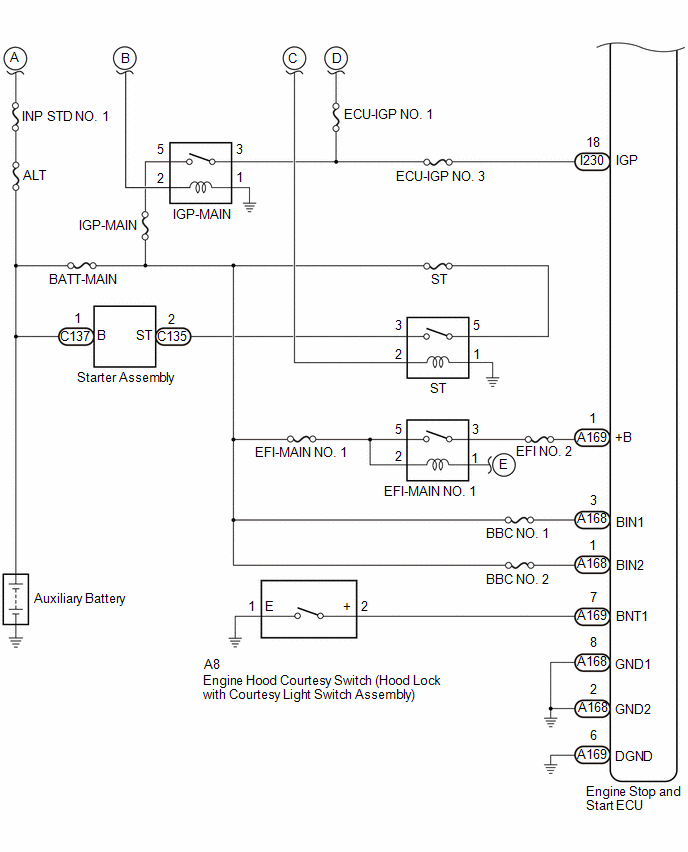

DESCRIPTION

The engine stop and start ECU uses its internal starter circuit to drive the starter drive relay (ST relay) and operate the starter.

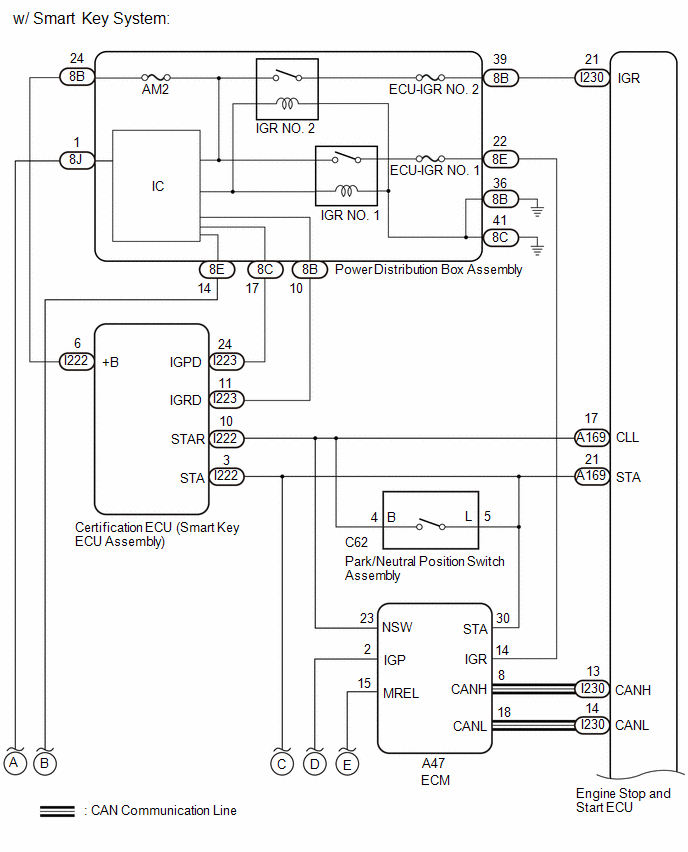

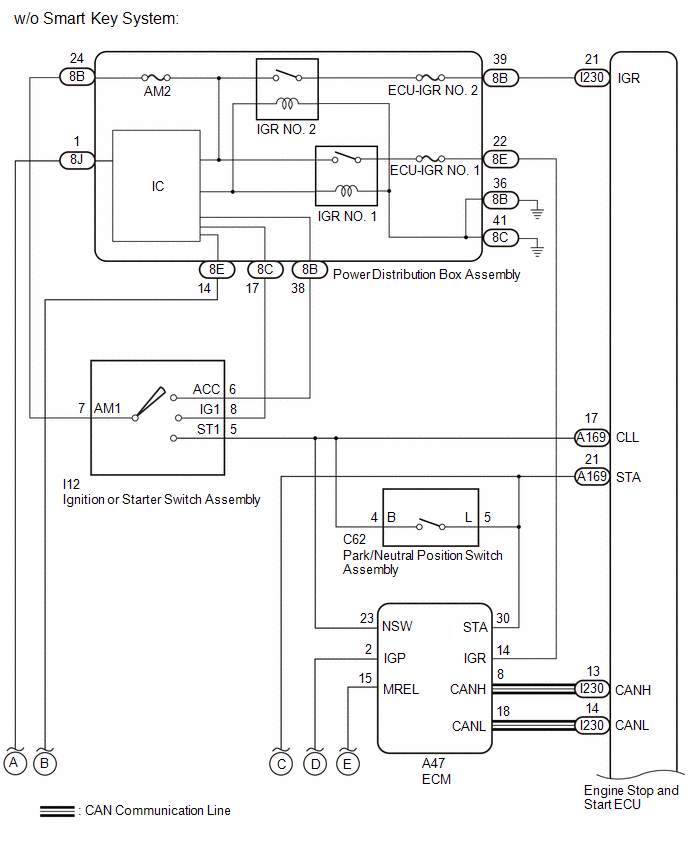

WIRING DIAGRAM

CAUTION / NOTICE / HINT

- When the engine stop and start ECU is replaced, read the number of starter operations before replacement and record this number to the new engine stop and start ECU after replacement.

Click here

.gif)

- When the engine stop ECU has been replaced, perform external backup boost converter (Eco run vehicle converter assembly) existence learning.

Click here

.gif)

- After replacing the engine stop and start ECU or air conditioner amplifier assembly, perform initialization/learning of the air conditioner information for the engine stop and start ECU.

Click here

.gif)

- When the starter assembly is replaced, the number of starter operations stored in the engine stop and start ECU must be reset.

Click here

.gif)

- When the engine stop and start ECU or oil pump with motor assembly is replaced, check the oil pump with motor assembly.

Click here

.gif)

- When the starter assembly is replaced, "ST relay" must be also replaced.

- Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

For wire harness and connector inspection procedures and precautions, refer to

.gif)

PROCEDURE

| 1. |

CHECK CRANKING |

(a) Turn the ignition switch START and check that the engine cranks.

|

Result | Proceed to |

|---|---|

|

Engine cranks | A |

|

Engine does not crank |

B |

| B |

.gif) | GO TO STEP 15 |

|

| 2. |

PERFORM ACTIVE TEST USING GTS (STARTER(HOOD CLOSE)) |

(a) Using the GTS, perform Active Test.

Powertrain > Stop and Start > Active Test|

Tester Display |

|---|

| Starter(Hood Close) |

(b) Check whether the engine cranks while the Active Test "Starter(Hood Close)" is being performed.

NOTICE:

The Active Test "Starter(Hood Close)" is stopped automatically 3 seconds after the starter assembly begins operating.

Standard:

Engine cranks

|

Result | Proceed to |

|---|---|

|

Engine cranks | A |

|

Engine does not crank |

B |

| B |

.gif) | GO TO STEP 14 |

|

| 3. |

CHECK VEHICLE CONTROL HISTORY (RoB) (ENGINE CONTROL SYSTEM) |

(a) Enter the following menus.

Powertrain > Engine > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Check the vehicle control history (RoB).

|

Result | Proceed to |

|---|---|

|

Engine control system Vehicle Control History (RoB) is not output |

A |

| Engine Difficult to Start is output |

B |

| Result other than Engine Difficult to Start is output |

C |

HINT:

- If the value of "Cranking Time" is approximately 1.5 seconds, the stop and start control system or starter system may be malfunctioning.

- If the value of "Cranking Time" is small (approximately 0.5 seconds or less: the minimum value varies depending on the model), the engine control system may be malfunctioning.

- The Data List item "Cranking Time" indicates the length of time starter operation is requested by the engine stop and start ECU. If the engine speed exceeds the specified value, the engine stop and start ECU cancels its start request.

| B | .gif) | GO TO STEP 6 |

| C |

.gif) | GO TO ENGINE CONTROL SYSTEM |

|

| 4. |

CHECK VEHICLE CONTROL HISTORY (RoB) |

(a) Enter the following menus.

Powertrain > Stop and Start > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select a vehicle control history (RoB) item to display the data from the time of control.

(c) Check the output data.

|

Tester Display | Result |

Proceed to |

|---|---|---|

| Engine Stall History during Stop&Start (Collision or Battery Voltage Low) |

Yes | A |

|

Engine Stall History during Engine Starting (Collision) |

Yes | |

| Engine Start Fail |

Yes | B |

|

Vehicle control history (RoB) item is not output or No is displayed for the results of all of the freeze frame data above | ||

| B |

.gif) | GO TO STEP 7 |

|

| 5. |

CHECK VEHICLE CONDITION (COLLISION HISTORY) |

(a) Check if the vehicle was in a collision when the engine stalled.

|

Result | Proceed to |

|---|---|

|

Vehicle was in collision when engine stalled |

A |

| Vehicle was not in collision when engine stalled |

B |

HINT:

When "Engine Stall History during Stop&Start (Collision or Battery Voltage Low)" or "Engine Stall History during Engine Starting (Collision)" is stored:

This may have been stored because the vehicle was in a collision or a collision detection signal was input while stop and start control was operating.

| A |

.gif) | END (ENGINE STALLED BECAUSE COLLISION DETECTION SIGNAL WAS RECEIVED) |

| B |

.gif) | GO TO AIRBAG SYSTEM |

| 6. |

CHECK VEHICLE CONTROL HISTORY (RoB) (ENGINE CONTROL SYSTEM) |

(a) Enter the following menus.

Powertrain > Engine > Utility|

Tester Display |

|---|

| Vehicle Control History (RoB) |

(b) Select Engine Difficult to Start from the Vehicle Control History (RoB) to display the data from the time of control.

(c) Check the output data.

HINT:

- Checking the freeze frame data allows the vehicle conditions at the time of detection to be confirmed.

- As Vehicle Control History (RoB) may be overwritten whenever the trigger conditions are met, make sure to save the Vehicle Control History (RoB) data before performing any inspections.

| Result |

Proceed to |

|---|---|

| Engine speed does not rise to approximately 300 rpm (Starter does not rotate) |

A |

| Engine speed rises to approximately 300 rpm (Starter rotates) |

B |

| A |

.gif) | GO TO STEP 4 |

| B |

.gif) | GO TO ENGINE CONTROL SYSTEM |

| 7. |

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ST RELAY) |

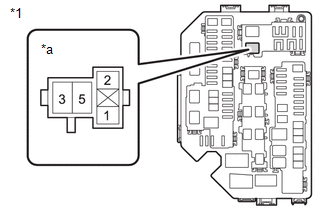

(a) Disconnect the I223 certification ECU (smart key ECU assembly) connector.*1

- *1: w/ Smart Key System

(b) Disconnect the C62 park/neutral position switch assembly connector.

(c) Disconnect the A47 ECM connector.

(d) Disconnect the A169 engine stop and start ECU connector.

(e) Remove the ST relay from the NO. 1 engine room relay block.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - ST relay terminal 2 |

Always | Below 1 Ω |

|

A169-21 (STA) - Body ground |

Always | 10 kΩ or higher |

|

ST relay terminal 2 - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 8. |

CHECK HARNESS AND CONNECTOR (ST RELAY - BODY GROUND) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

ST relay terminal 1 - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 9. |

CHECK HARNESS AND CONNECTOR (ST RELAY - AUXILIARY BATTERY) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 10. |

CHECK HARNESS AND CONNECTOR (STARTER ASSEMBLY - AUXILIARY BATTERY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

NOTICE: Before performing this step, check that the starter assembly connector C137 is not disconnected or loose. |

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11. |

CHECK HARNESS AND CONNECTOR (ST RELAY - STARTER ASSEMBLY) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

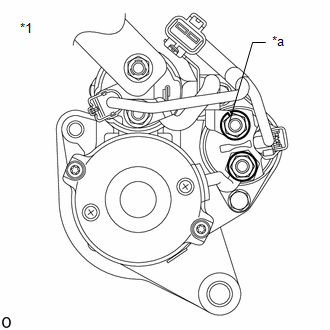

(b) Disconnect the C135 starter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

ST relay terminal 3 - C135-2 (ST) |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 12. |

INSPECT RELAY (ST RELAY) |

Click here

.gif)

| NG | .gif) |

REPLACE RELAY (ST RELAY) |

|

| 13. |

INSPECT STARTER ASSEMBLY |

Click here

.gif)

| OK | .gif) |

REPLACE ENGINE STOP AND START ECU HINT: If arriving at this item from the item "Drive command is being sent from the engine stop and start ECU but the starter itself is not moving" of "After Engine Stops due to Stop and Start System, Engine does not Restart" in Stop and Start / Stop and Start System / Problem Symptoms Table, go to SIMULATION METHOD. |

| NG | .gif) | REPLACE STARTER ASSEMBLY |

| 14. |

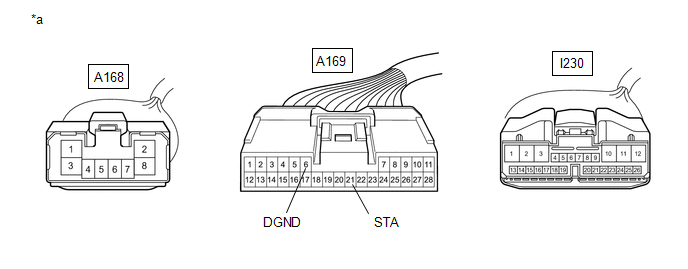

CHECK HARNESS AND CONNECTOR (STA SIGNAL) |

(a) Disconnect the engine stop and start ECU connectors.

|

*a | Front view of wire harness connector (to Engine Stop and Start ECU) |

- | - |

(b) Measure the voltage according to the value(s) in the table below.

Click here

.gif)

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - A169-6 (DGND) |

Cranking commanded via Active Test item Starter(Hood Close) |

6 to 14 V |

HINT:

The Active Test "Starter" is stopped automatically 3 seconds after the starter assembly begins operating.

| OK | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (ENGINE STOP AND START ECU - ST RELAY) |

| NG | .gif) | REPLACE ENGINE STOP AND START ECU HINT: If arriving at this item from the item "Drive command is being sent from the engine stop and start ECU but the starter itself is not moving" of "After Engine Stops due to Stop and Start System, Engine does not Restart" in Stop and Start / Stop and Start System / Problem Symptoms Table, go to SIMULATION METHOD. |

| 15. |

PERFORM ACTIVE TEST USING GTS (STARTER(HOOD CLOSE)) |

(a) Using the GTS, perform Active Test.

Powertrain > Stop and Start > Active Test|

Tester Display |

|---|

| Starter(Hood Close) |

(b) Check whether the engine cranks while the Active Test "Starter(Hood Close)" is being performed.

NOTICE:

The Active Test "Starter(Hood Close)" is stopped automatically 3 seconds after the starter assembly begins operating.

Standard:

Engine cranks

|

Result | Proceed to |

|---|---|

|

Engine cranks | A |

|

Engine does not crank |

B |

| B |

.gif) | GO TO STEP 26 |

|

| 16. |

READ VALUE USING GTS (NEUTRAL SWITCH) |

(a) In accordance with the display on the GTS, read the Data List.

Powertrain > Stop and Start > Data List|

Tester Display |

|---|

| Neutral Switch |

OK:

|

Tester Display | Condition |

Normal Condition |

|---|---|---|

|

Neutral Switch | Shift lever in P or N |

ON |

| Shift lever not in P or N |

OFF |

|

Result | Proceed to |

|---|---|

|

OK (w/ Smart Key System) | A |

|

OK (w/o Smart Key System) |

B |

| NG |

C |

| B |

.gif) | GO TO STEP 19 |

| C |

.gif) | GO TO STEP 21 |

|

| 17. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ENGINE STOP AND START ECU) |

(a) Disconnect the C62 park/neutral position switch assembly connector.

(b) Disconnect the I223 certification ECU (smart key ECU assembly) connector.

(c) Disconnect the A169 engine stop and start ECU connector.

(d) Disconnect the A47 ECM connector.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I223-10 (STAR) - A169-17 (CLL) |

Always | Below 1 Ω |

|

I223-10 (STAR) - C62-4 (B) |

Always | Below 1 Ω |

|

I223-10 (STAR) - Body ground |

Always | 10 kΩ or higher |

|

A169-17 (CLL) - Body ground |

Always | 10 kΩ or higher |

|

C62-4 (B) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 18. |

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) (STAR SIGNAL) |

(a) Disconnect A169 the engine stop and start ECU connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Switch Condition |

Specified Condition |

|---|---|---|

|

A169-17 (CLL) - Body ground |

Engine started using ignition switch (ignition switch turned to START) |

9.5 to 14 V |

| OK | .gif) | SIMULATION METHOD TO CHECK |

| NG | .gif) | GO TO SMART KEY SYSTEM (START FUNCTION) |

| 19. |

CHECK HARNESS AND CONNECTOR (IGNITION OR STARTER SWITCH ASSEMBLY - ENGINE STOP AND START ECU) |

(a) Disconnect the C62 park/neutral position switch assembly connector.

(b) Disconnect the I12 Ignition or Starter Switch Assembly connector.

(c) Disconnect the A169 engine stop and start ECU connector.

(d) Disconnect the A47 ECM connector.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I12-5 (ST1) - A169-17 (CLL) |

Always | Below 1 Ω |

|

I12-5 (ST1) - C62-4 (B) |

Always | Below 1 Ω |

|

I12-5 (ST1) - Body ground |

Always | 10 kΩ or higher |

|

A169-17 (CLL) - Body ground |

Always | 10 kΩ or higher |

|

C62-4 (B) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 20. |

CHECK IGNITION OR STARTER SWITCH ASSEMBLY (ST1 SIGNAL) |

(a) Disconnect A169 the engine stop and start ECU connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Switch Condition |

Specified Condition |

|---|---|---|

|

A169-17 (CLL) - Body ground |

Engine started using ignition switch (ignition switch turned to START) |

9.5 to 14 V |

| OK | .gif) | SIMULATION METHOD TO CHECK |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 21. |

CHECK VEHICLE SPECIFICATION |

(a) Check the vehicle specification,

| Result |

Proceed to |

|---|---|

| for 2WD |

A |

| for AWD |

B |

| B |

.gif) | GO TO STEP 24 |

|

| 22. |

INSPECT PARK/NEUTRAL POSITION SWITCH |

Click here

.gif)

| NG | .gif) |

REPLACE PARK/NEUTRAL POSITION SWITCH |

|

| 23. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ST RELAY) |

(a) Disconnect the I223 certification ECU (smart key ECU assembly) connector.

(b) Remove the ST relay from the NO. 1 engine room relay block.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I223-10 (STAR) - ST relay terminal 1 |

Shift lever in P or N |

Below 1 Ω |

|

I223-3 (STA) - Body ground |

Shift lever not in P or N |

10 kΩ or higher |

| OK | .gif) | REPLACE ENGINE STOP AND START ECU HINT: If arriving at this item from the item "Drive command is being sent from the engine stop and start ECU but the starter itself is not moving" of "After Engine Stops due to Stop and Start System, Engine does not Restart" in Stop and Start / Stop and Start System / Problem Symptoms Table, go to SIMULATION METHOD. |

| NG | .gif) | REPLACE PARK/NEUTRAL POSITION SWITCH |

| 24. |

INSPECT PARK/NEUTRAL POSITION SWITCH |

Click here

.gif)

| NG | .gif) |

REPLACE PARK/NEUTRAL POSITION SWITCH |

|

| 25. |

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - ST RELAY) |

(a) Disconnect the I223 certification ECU (smart key ECU assembly) connector.

(b) Remove the ST relay from the NO. 1 engine room relay block.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

I223-10 (STAR) - ST relay terminal 1 |

Shift lever in P or N |

Below 1 Ω |

|

I223-3 (STA) - Body ground |

Shift lever not in P or N |

10 kΩ or higher |

| OK | .gif) | REPLACE ENGINE STOP AND START ECU HINT: If arriving at this item from the item "Drive command is being sent from the engine stop and start ECU but the starter itself is not moving" of "After Engine Stops due to Stop and Start System, Engine does not Restart" in Stop and Start / Stop and Start System / Problem Symptoms Table, go to SIMULATION METHOD. |

| NG | .gif) | REPLACE PARK/NEUTRAL POSITION SWITCH |

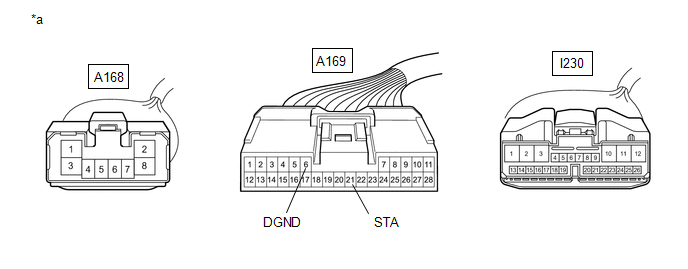

| 26. |

CHECK HARNESS AND CONNECTOR (STA SIGNAL) |

(a) Disconnect the A169 engine stop and start ECU connector.

|

*a | Front view of wire harness connector (to Engine Stop and Start ECU) |

- | - |

(b) Measure the voltage according to the value(s) in the table below.

Click here

.gif)

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - A169-6 (DGND) |

Engine start | 6 to 14 V |

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG | B |

| B |

.gif) | GO TO STEP 32 |

|

| 27. |

INSPECT RELAY (ST RELAY) |

Click here

.gif)

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 28. |

CHECK HARNESS AND CONNECTOR (ST RELAY - AUXILIARY BATTERY) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

| (b) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 29. |

CHECK HARNESS AND CONNECTOR (ST RELAY - STARTER ASSEMBLY) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

(b) Disconnect the C135 starter assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

ST relay terminal 3 - C135-2 (ST) |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 30. |

CHECK HARNESS AND CONNECTOR (ST RELAY - BODY GROUND) |

(a) Remove the ST relay from the NO. 1 engine room relay block.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

ST relay terminal 1 - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 31. |

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ST RELAY) |

(a) Disconnect the I223 certification ECU (smart key ECU assembly) connector.*1

- *1: w/ Smart Key System

(b) Disconnect the C62 park/neutral position switch assembly connector.

(c) Disconnect the A47 ECM connector.

(d) Disconnect the A169 engine stop and start ECU connector.

(e) Remove the ST relay from the NO. 1 engine room relay block.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - ST relay terminal 2 |

Always | Below 1 Ω |

|

A169-21 (STA) - Body ground |

Always | 10 kΩ or higher |

|

ST relay terminal 2 - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE STARTER ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

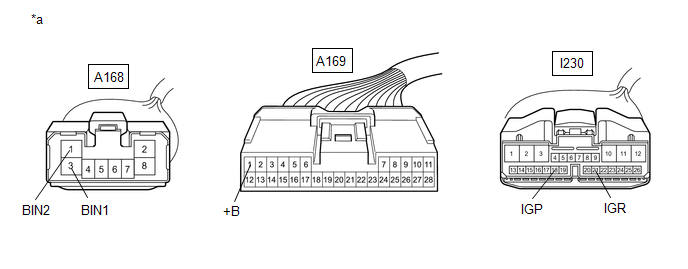

| 32. |

CHECK HARNESS AND CONNECTOR (POWER SUPPLY CIRCUIT) |

(a) Disconnect the A168, A169 and I230 engine stop and start ECU connectors.

|

*a | Front view of wire harness connector (to Engine Stop and Start ECU) |

- | - |

(b) Measure the voltage according to the value(s) in the table below.

Click here

.gif)

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A168-3 (BIN1) - Body ground |

Always | 9.5 to 14 V |

|

A168-1 (BIN2) - Body ground |

Always | 9.5 to 14 V |

(c) Turn the ignition switch to ON.

(d) Measure the voltage according to the value(s) in the table below.

Click here .gif)

Standard Voltage:

|

Tester Connection | Switch Condition |

Specified Condition |

|---|---|---|

|

A169-1 (+B) - Body ground |

Ignition switch ON | 9.5 to 14 V |

|

I230-18 (IGP) - Body ground |

Ignition switch ON | 9.5 to 14 V |

|

I230-21 (IGR) - Body ground |

Ignition switch ON | 9.5 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 33. |

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - BODY GROUND) |

(a) Disconnect the A168 and A169 engine stop and start ECU connectors.

(b) Measure the resistance according to the value(s) in the table below.

Click here .gif)

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A168-2 (GND2) - Body ground |

Always | Below 1 Ω |

|

A168-8 (GND1) - Body ground |

Always | Below 1 Ω |

|

A169-6 (DGND) - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 34. |

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ST RELAY) |

(a) Disconnect the I223 certification ECU (smart key ECU assembly) connector.*1

- *1: w/ Smart Key System

(b) Disconnect the C62 park/neutral position switch assembly connector.

(c) Disconnect the A47 ECM connector.

(d) Disconnect the A169 engine stop and start ECU connector.

(e) Remove the ST relay from the NO. 1 engine room relay block.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A169-21 (STA) - ST relay terminal 2 |

Always | Below 1 Ω |

|

A169-21 (STA) - Body ground |

Always | 10 kΩ or higher |

|

ST relay terminal 2 - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE ENGINE STOP AND START ECU HINT: If arriving at this item from the item "Drive command is being sent from the engine stop and start ECU but the starter itself is not moving" of "After Engine Stops due to Stop and Start System, Engine does not Restart" in Stop and Start / Stop and Start System / Problem Symptoms Table, go to SIMULATION METHOD. |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)