Toyota Corolla Cross: Removal

REMOVAL

CAUTION / NOTICE / HINT

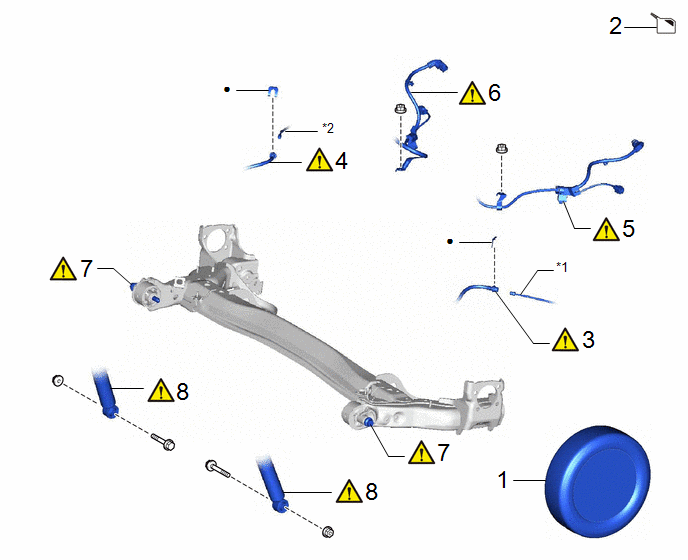

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

REAR WHEELS |

- |

- |

- |

- |

|

2 |

DRAIN BRAKE FLUID |

- |

- |

|

- |

|

3 |

REAR BRAKE TUBE FLEXIBLE HOSE LH |

- |

|

- |

- |

|

4 |

REAR BRAKE TUBE FLEXIBLE HOSE RH |

- |

|

- |

- |

|

5 |

SKID CONTROL SENSOR WIRE LH |

89544E |

|

- |

- |

|

6 |

SKID CONTROL SENSOR WIRE RH |

89544D |

|

- |

- |

|

7 |

REAR AXLE BEAM ASSEMBLY |

42110F |

|

- |

- |

|

8 |

SEPARATE REAR SHOCK ABSORBER ASSEMBLY |

- |

|

- |

- |

|

*1 |

REAR NO. 4 BRAKE TUBE |

*2 |

REAR NO. 3 BRAKE TUBE |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

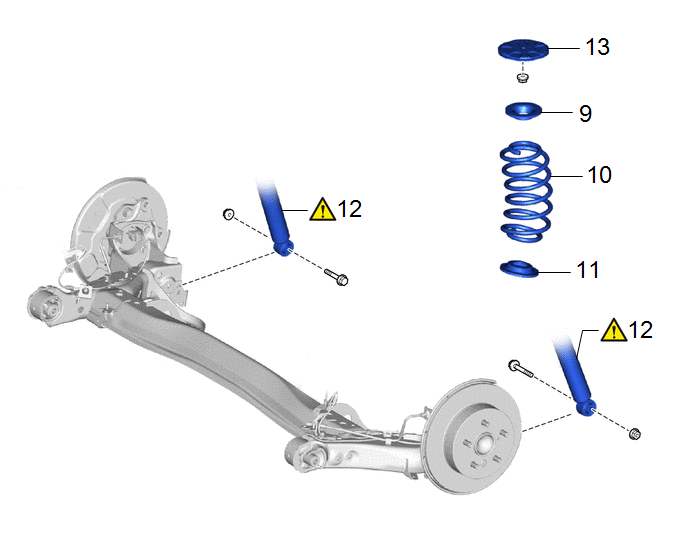

9 |

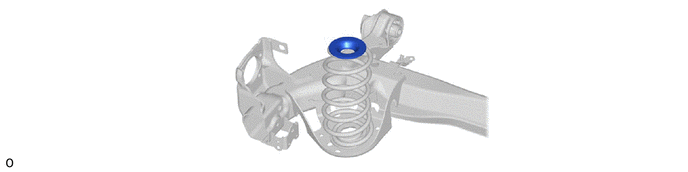

REAR UPPER COIL SPRING INSULATOR |

48259A |

- |

- |

- |

|

10 |

REAR COIL SPRING |

48231B |

- |

- |

- |

|

11 |

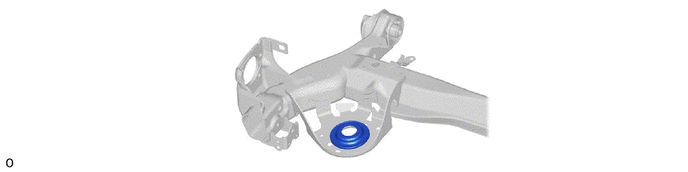

REAR LOWER COIL SPRING INSULATOR |

48258C |

- |

- |

- |

|

12 |

TEMPORARILY INSTALL REAR SHOCK ABSORBER ASSEMBLY |

- |

|

- |

- |

|

13 |

REAR SPRING SEAT SUB-ASSEMBLY |

42011 |

- |

- |

- |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear coil spring removal/ installation are shown below.

Necessary Procedures After Procedure Performed|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Rear wheel alignment adjustment |

|

|

|

|

Dynamic torque control AWD system |

|

|

|

Suspension, tires, etc. |

Rear television camera assembly optical axis (Back camera position setting) |

Parking Assist Monitor System |

|

|

Initialize headlight ECU subassembly LH |

Automatic headlight beam level control system |

|

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE REAR WHEELS

Click here .gif)

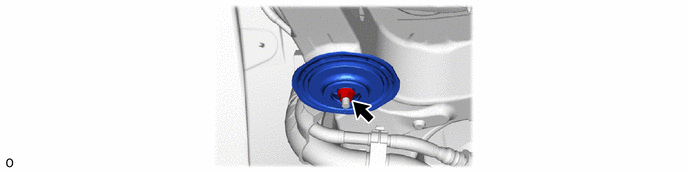

2. DRAIN BRAKE FLUID

.png) |

NOTICE: If brake fluid leaks onto any painted surface, immediately wash it off. |

3. SEPARATE REAR BRAKE TUBE FLEXIBLE HOSE LH

(1) Using a union nut wrench, separate the rear brake tube flexible hose LH from the rear No. 4 brake tube while holding the rear brake tube flexible hose with a wrench.

NOTICE:

- Do not kink or damage the brake line.

- Do not allow any foreign matter such as dirt or dust to enter the brake line from the connecting parts.

(2) Remove the clip and separate the rear brake tube flexible hose LH from the rear axle beam assembly.

4. SEPARATE REAR BRAKE TUBE FLEXIBLE HOSE RH

(a) Perform the same procedure as for the LH side.

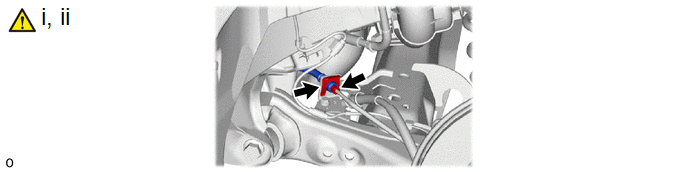

5. SEPARATE SKID CONTROL SENSOR REAR LH

(1) Using a screwdriver with its tip wrapped in protective tape, disconnect the skid control sensor wire LH from the rear axle hub and bearing assembly.

NOTICE:

Be careful not to damage the rear axle hub and bearing assembly and connector cover.

(2) Disengage the clamp.

(3) Disconnect the No. 2 parking brake wire assembly connector from the parking brake actuator assembly.

(4) Remove the bolt and disengage hook to separate the skid control sensor wire LH.

6. SEPARATE SKID CONTROL SENSOR REAR RH

(a) Perform the same procedure as for the LH side.

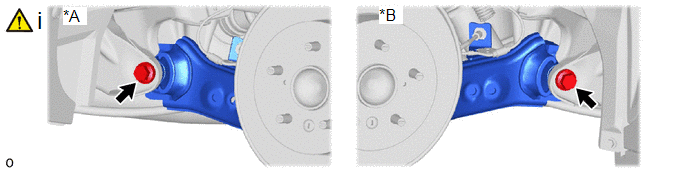

7. LOOSEN REAR AXLE BEAM ASSEMBLY

|

*A |

for LH Side |

*B |

for RH Side |

(1) Loosen the 2 bolts.

NOTICE:

Do not remove the bolts.

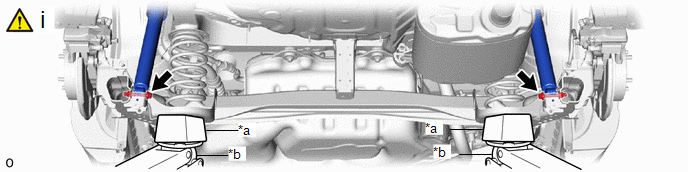

8. SEPARATE REAR SHOCK ABSORBER ASSEMBLY

|

*a |

Wooden Block |

*b |

Jack |

(1) Support the spring seat of the rear axle beam assembly using 2 jacks and 2 wooden blocks.

CAUTION:

Do not jack up the rear axle beam assembly too high as the vehicle may fall.

NOTICE:

- When jacking up the rear axle beam assembly, be sure to jack it up slowly.

- Make sure to perform this operation with the vehicle kept as low as possible.

- Keep supporting the rear axle beam assembly with a jack until the installation of the rear coil spring is completed.

(2) Remove the 2 bolts while holding the 2 nuts and separate the rear axle beam assembly from the rear shock absorber assemblies LH and RH.

NOTICE:

Because the nuts have their own stoppers, do not turn the nuts. Loosen the bolts with the nuts secured.

(3) Slowly lower the rear axle beam assembly using 2 jacks and 2 wooden blocks.

9. REMOVE REAR UPPER COIL SPRING INSULATOR

10. REMOVE REAR COIL SPRING

11. REMOVE REAR LOWER COIL SPRING INSULATOR

12. TEMPORARILY INSTALL REAR SHOCK ABSORBER ASSEMBLY

|

*a |

Wooden Block |

*b |

Jack |

(1) Slowly jack up the rear axle beam assembly using 2 jacks and 2 wooden blocks, and temporarily install the rear axle beam assembly to the rear shock absorber assemblies LH and RH with the 2 bolts and 2 nuts.

NOTICE:

Because the nut has its own stopper, do not turn the nut. Tighten the bolt with the nut secured.

13. REMOVE REAR SPRING SEAT SUB-ASSEMBLY

.png) |

HINT: Perform this procedure only when replacement of the rear spring seat sub-assembly is necessary. |