Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

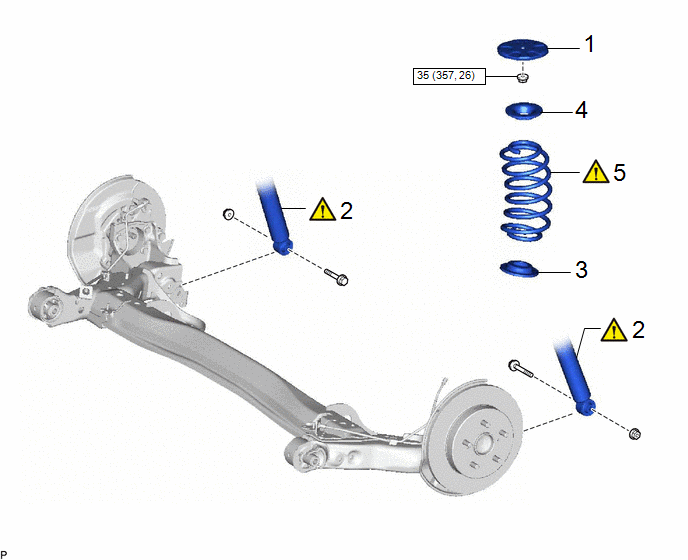

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

REAR SPRING SEAT SUB-ASSEMBLY |

42011 |

- |

- |

- |

|

2 |

SEPARATE REAR SHOCK ABSORBER ASSEMBLY |

- |

|

- |

- |

|

3 |

REAR LOWER COIL SPRING INSULATOR |

48258C |

- |

- |

- |

|

4 |

REAR UPPER COIL SPRING INSULATOR |

48259A |

- |

- |

- |

|

5 |

REAR COIL SPRING |

48231B |

|

- |

- |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

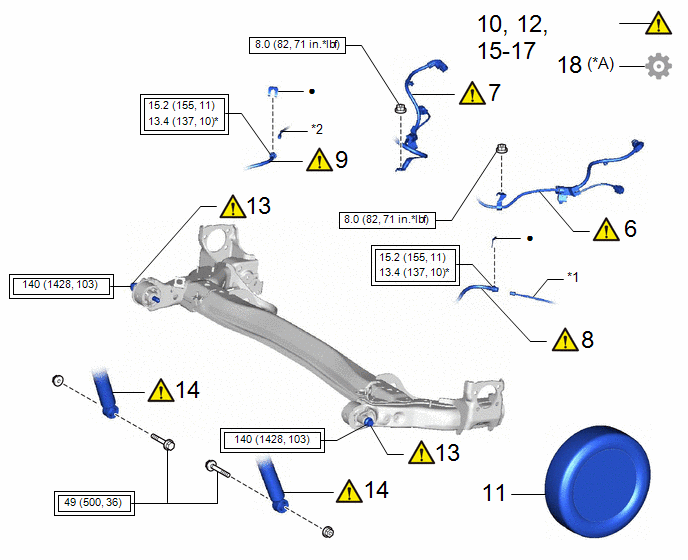

6 |

SKID CONTROL SENSOR WIRE LH |

89544E |

|

- |

- |

|

7 |

SKID CONTROL SENSOR WIRE RH |

89544D |

|

- |

- |

|

8 |

REAR BRAKE TUBE FLEXIBLE HOSE LH |

- |

|

- |

- |

|

9 |

REAR BRAKE TUBE FLEXIBLE HOSE RH |

- |

|

- |

- |

|

10 |

BLEED BRAKE LINE |

- |

|

- |

- |

|

11 |

REAR WHEELS |

- |

- |

- |

- |

|

12 |

STABILIZE SUSPENSION |

- |

|

- |

- |

|

13 |

REAR AXLE BEAM ASSEMBLY |

42110F |

|

- |

- |

|

14 |

INSTALL REAR SHOCK ABSORBER ASSEMBLY |

- |

|

- |

- |

|

15 |

CHECK FOR SPEED SENSOR SIGNAL |

- |

|

- |

- |

|

16 |

INSPECT REAR WHEEL ALIGNMENT |

- |

|

- |

- |

|

17 |

PLACE FRONT WHEELS FACING STRAIGHT AHEAD |

- |

|

- |

- |

|

18 |

PERFORM CALIBRATION |

- |

- |

- |

|

|

*A |

w/ Parking Assist Monitor System |

- |

- |

|

*1 |

REAR NO. 4 BRAKE TUBE |

*2 |

REAR NO. 3 BRAKE TUBE |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

* |

For use with a union nut wrench |

● |

Non-reusable part |

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The procedure listed below is for the LH side.

PROCEDURE

1. INSTALL REAR SPRING SEAT SUB-ASSEMBLY

.png) |

HINT: Perform this procedure only when replacement of the rear spring seat sub-assembly is necessary. |

Torque:

35 N·m {357 kgf·cm, 26 ft·lbf}

2. SEPARATE REAR SHOCK ABSORBER ASSEMBLY

.png) |

Click here |

3. INSTALL REAR LOWER COIL SPRING INSULATOR

4. INSTALL REAR UPPER COIL SPRING INSULATOR

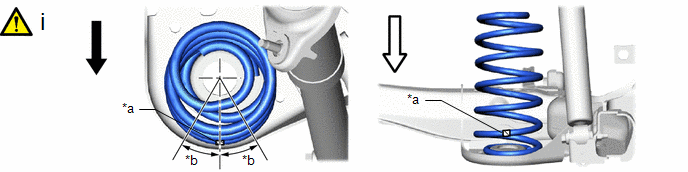

5. INSTALL REAR COIL SPRING

|

*a |

Identification Mark |

*b |

30° |

.png) |

Rear of the Vehicle |

.png) |

Lower of the Vehicle |

(1) Set the rear coil spring to the rear axle beam assembly as shown in the illustration.

NOTICE:

Make sure that the identification mark is positioned on the lower side of the vehicle.

.png)

|

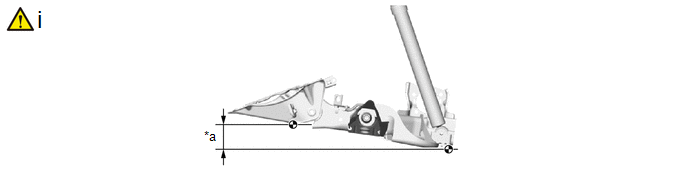

*a |

Wooden Block |

*b |

Jack |

(1) Slowly jack up the rear axle beam assembly using 2 jacks and 2 wooden blocks and temporarily install the rear axle beam assembly and rear coil spring with the 2 bolts and 2 nuts.

NOTICE:

Because the nuts have their own stoppers, do not turn the nuts. Tighten the bolts with the nuts secured.

6. INSTALL SKID CONTROL SENSOR REAR LH

.png) |

NOTICE: Do not twist the skid control sensor wire when installing it. |

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

7. INSTALL SKID CONTROL SENSOR REAR RH

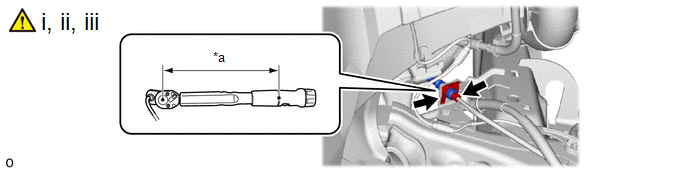

8. CONNECT REAR BRAKE TUBE FLEXIBLE HOSE LH

|

*a |

Torque Wrench Fulcrum Length |

- |

- |

(1) Temporarily install the rear brake tube flexible hose LH to the rear No. 4 brake tube.

(2) Secure the rear brake tube flexible hose LH with a new clip.

NOTICE:

Install the clip as far as it will go.

(3) Using a union nut wrench, connect the rear brake tube flexible hose LH to the rear No. 4 brake tube while holding the rear brake tube flexible hose with a wrench.

Torque:

Specified tightening torque :

15.2 N·m {155 kgf·cm, 11 ft·lbf}

NOTICE:

- Do not kink or damage the brake line.

- Do not allow any foreign matter such as dirt or dust to enter the brake line from the connecting parts.

HINT:

- Calculate the torque wrench reading when changing the fulcrum length of

the torque wrench.

Click here

.gif)

.gif)

- When using a union nut wrench (fulcrum length of 22 mm (0.866 in.)) + torque

wrench (fulcrum length of 162 mm (6.38 in.)):

13.4 N*m (137 kgf*cm, 10 ft.*lbf)

9. CONNECT REAR BRAKE TUBE FLEXIBLE HOSE RH

10. BLEED BRAKE LINE

Click here .gif)

.gif)

11. INSTALL REAR WHEELS

Click here .gif)

12. STABILIZE SUSPENSION

Click here .gif)

13. INSTALL REAR AXLE BEAM ASSEMBLY

|

*a |

70 mm (2.76 in.) |

- |

- |

(1) Install the rear axle beam assembly as shown in the illustration.

Torque:

140 N·m {1428 kgf·cm, 103 ft·lbf}

14. INSTALL REAR SHOCK ABSORBER ASSEMBLY

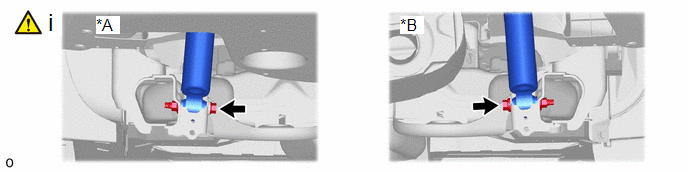

|

*A |

for LH Side |

*B |

for RH Side |

(1) Install the rear axle beam assembly to the rear shock absorber assemblies LH and RH with the 2 bolts.

Torque:

49 N·m {500 kgf·cm, 36 ft·lbf}

NOTICE:

Because the nuts have their own stoppers, do not turn the nuts. Tighten the bolts with the nuts secured.

15. CHECK FOR SPEED SENSOR SIGNAL

Click here .gif)

.gif)

16. INSPECT REAR WHEEL ALIGNMENT

Click here .gif)

17. PLACE FRONT WHEELS FACING STRAIGHT AHEAD

Click here .gif)

.gif)

18. PERFORM CALIBRATION (w/ Parking Assist Monitor System)

|

Parking assist monitor system |

|

|

Automatic headlight beam level control system |

|