Toyota Corolla Cross: Removal

REMOVAL

CAUTION / NOTICE / HINT

COMPONENTS (REMOVAL)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY |

77020A | - |

- | - |

|

2 | FUEL TANK VENT TUBE ASSEMBLY |

77010 | - |

- | - |

|

3 | DRAIN FUEL |

- |

|

- | - |

|

4 | EXHAUST PIPE ASSEMBLY |

- | - |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

5 | NO. 2 FUEL TANK PROTECTOR |

77642A | - |

- | - |

|

6 | NO. 1 FUEL TANK PROTECTOR |

77641A | - |

- | - |

|

7 | FUEL TANK BREATHER TUBE |

- |

|

- | - |

|

8 | FUEL TANK TO FILLER PIPE HOSE |

77210 | - |

- | - |

|

9 | FUEL TANK MAIN TUBE SUB-ASSEMBLY |

77209F |

|

- | - |

|

10 | FUEL CUT OFF W/TUBE |

- |

|

- | - |

|

11 | FUEL TANK ASSEMBLY |

77100 |

|

- | - |

|

12 | NO. 6 FUEL TANK CUSHION |

77656B | - |

- | - |

|

● | Non-reusable part |

- | - |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during fuel pump removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Gas leak from exhaust system is repaired |

Inspection After Repair |

|

|

CAUTION:

- Never perform work on fuel system components near any possible ignition sources.

.png)

- Vaporized fuel could ignite, resulting in a serious accident.

- Do not perform work on fuel system components without first disconnecting the cable from the negative (-) battery terminal.

.png)

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

- Because the weight of the fuel tank sub-assembly is extremely heavy, make sure to follow the work procedures described in the repair manual.

.png)

- If work is not performed according to the procedures described in the repair manual, there is a danger that the components could fall down.

- When the engine is hot, do not touch high-temperature areas such as the engine or exhaust pipe.

- Touching high-temperature areas such as the engine and exhaust pipe could result in burns.

HINT:

When the cable is disconnected / reconnected to the battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

- Learning completes when vehicle is driven.

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Front camera system

Drive the vehicle straight ahead at 15 km/h (10 mph) or more for 1 second or more.

.gif)

Stop and start system

Drive the vehicle until stop and start control is permitted (approximately 5 to 60 minutes)

.gif)

- Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

.gif)

Power back door system

Fully close the back door by hand.

HINT:

Initialization is not necessary if the above procedures are performed while the back door is closed.

.gif)

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. REMOVE FUEL SUCTION TUBE WITH PUMP AND GAUGE ASSEMBLY

Click here .gif)

2. REMOVE FUEL TANK VENT TUBE ASSEMBLY

Click here .gif)

3. DRAIN FUEL

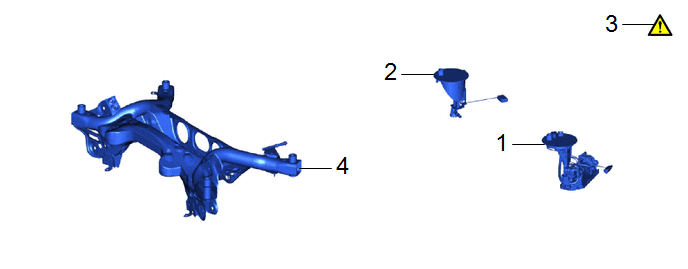

4. REMOVE REAR SUSPENSION MEMBER SUB-ASSEMBLY

Click here .gif)

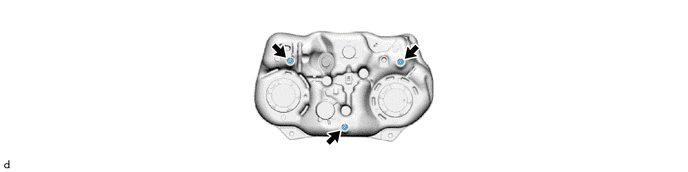

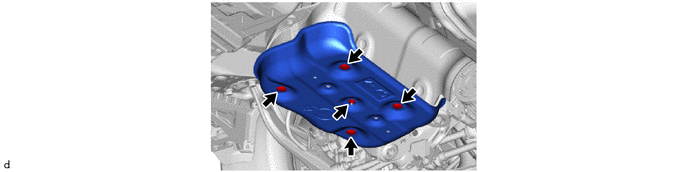

5. REMOVE NO. 2 FUEL TANK PROTECTOR

6. REMOVE NO. 1 FUEL TANK PROTECTOR

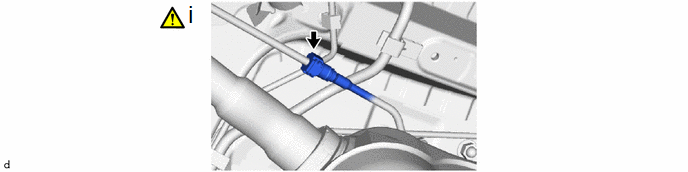

7. DISCONNECT FUEL TANK BREATHER TUBE

(1) Disconnect the fuel tank breather tube from the fuel tank filler pipe sub-assembly.

Click here .gif)

8. DISCONNECT FUEL TANK TO FILLER PIPE HOSE

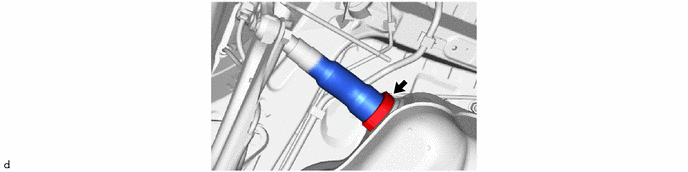

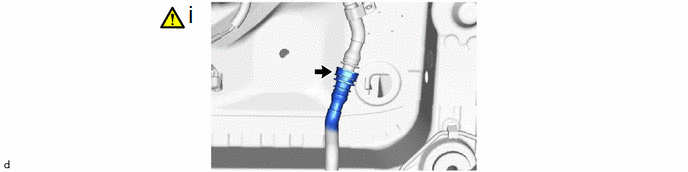

9. DISCONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY

(1) Disconnect the fuel tube connector to remove the fuel tank main tube sub-assembly from the fuel pipe.

Click here .gif)

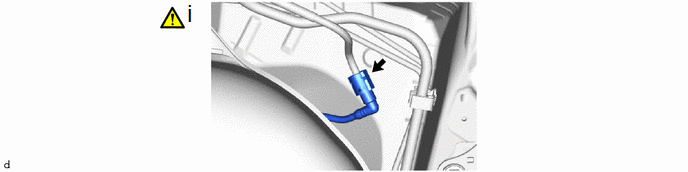

10. DISCONNECT FUEL CUT OFF W/TUBE

(1) Disconnect the fuel tube connector to remove the FUEL CUT OFF W/TUBE from the FUEL TANK VENT HOSE SUB-ASSEMBLY.

Click here .gif)

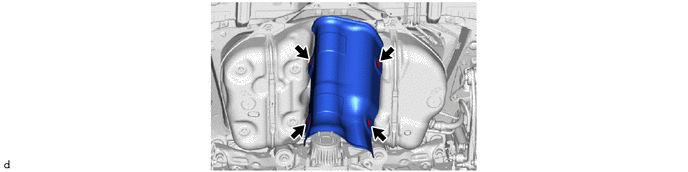

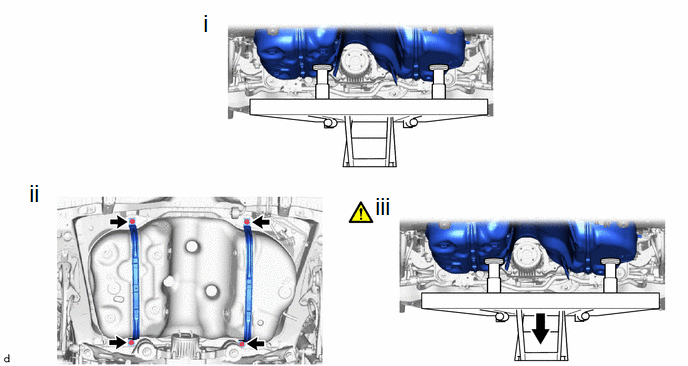

11. REMOVE FUEL TANK ASSEMBLY

.png) |

CAUTION: The fuel tank assembly is very heavy. Be sure to follow the procedure described in the repair manual, or the fuel tank assembly may fall off the engine lifter. .png) |

(1) Support the fuel tank assembly using an engine lifter.

HINT:

Using height adjustment attachments and plate lift attachments, keep the fuel tank assembly horizontal.

(2) Remove the 4 bolts and No. 1 fuel tank band sub-assemblies.

(3) Lower the engine lifter to remove the fuel tank assembly.

NOTICE:

- Be careful not to drop the fuel tank assembly.

- When removing the fuel tank assembly, tilt it slightly to prevent it from interfering with the surrounding parts.

12. REMOVE NO. 6 FUEL TANK CUSHION