Toyota Corolla Cross: Removal

REMOVAL

CAUTION / NOTICE / HINT

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

PRECAUTION |

- |

|

- |

- |

|

2 |

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM |

- |

|

- |

- |

|

3 |

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

- |

- |

- |

- |

|

4 |

DRAIN BRAKE FLUID |

- |

- |

|

- |

|

5 |

WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

- |

- |

- |

- |

|

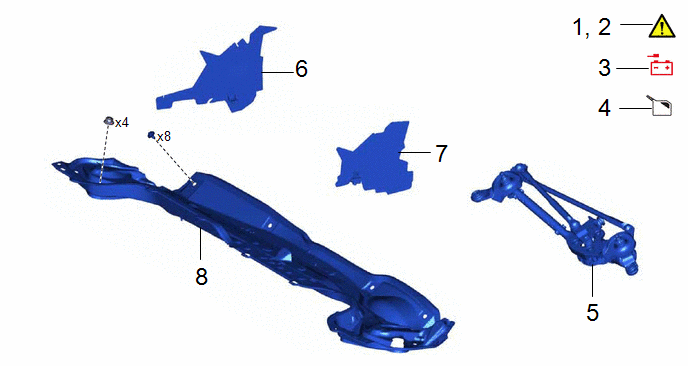

6 |

NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL |

55737B |

- |

- |

- |

|

7 |

WATER GUARD PLATE |

55734D |

- |

- |

- |

|

8 |

OUTER COWL TOP PANEL SUB-ASSEMBLY |

55701J |

- |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

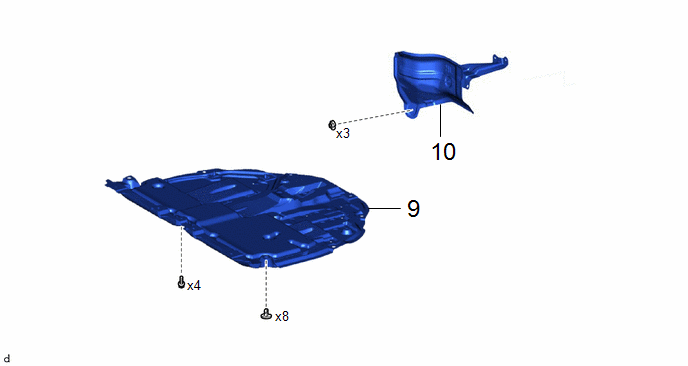

9 |

NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 |

- |

- |

- |

|

10 |

DASH PANEL HEAT INSULATOR |

- |

- |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

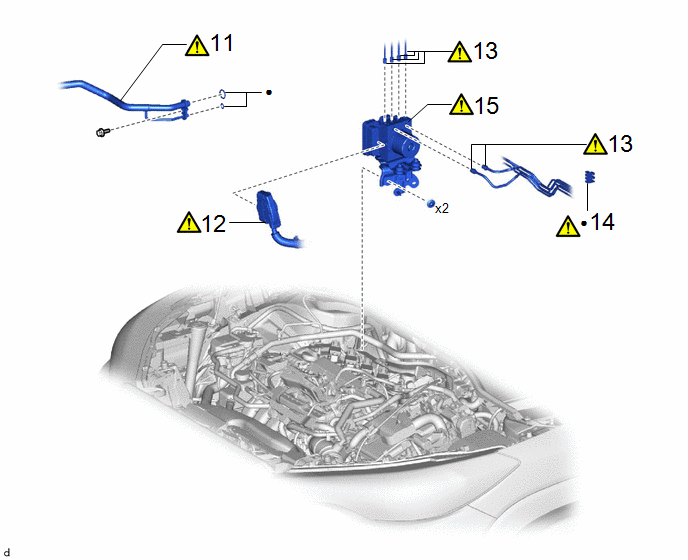

11 |

AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY |

88710E |

|

- |

- |

|

12 |

ENGINE ROOM MAIN WIRE |

- |

|

- |

- |

|

13 |

BRAKE LINE |

- |

|

- |

- |

|

14 |

NO. 3 BRAKE TUBE CLAMP |

47373B |

|

- |

- |

|

15 |

BRAKE ACTUATOR WITH BRACKET |

- |

|

- |

- |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

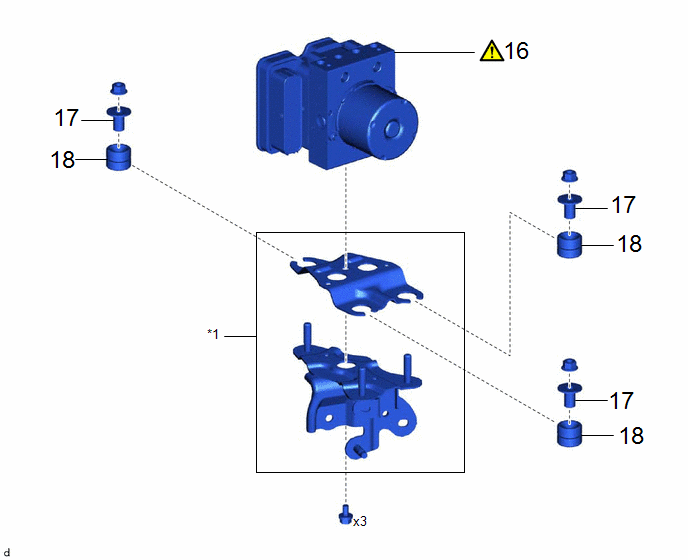

16 |

BRAKE ACTUATOR ASSEMBLY |

44510 |

|

- |

- |

|

17 |

NO. 1 BRAKE ACTUATOR CASE COLLAR |

44521A |

- |

- |

- |

|

18 |

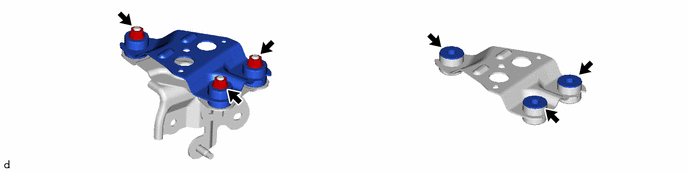

BRAKE ACTUATOR BRACKET CUSHION |

44547B |

- |

- |

- |

|

*1 |

BRAKE ACTUATOR BRACKET ASSEMBLY |

- |

- |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during brake actuator assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: Even when not replacing the part, it is necessary to perform the specified necessary procedures after installation. | |||

|

Skid control ECU (brake actuator assembly) |

Update ECU security key (Only necessary after replacement) |

Vehicle Control History (RoB) are stored |

|

|

|

|

|

|

Operate the electric parking brake switch |

Electric Parking Brake System |

|

|

HINT:

When the cable is disconnected/reconnected to the auxiliary battery terminal, systems temporarily stop operating. However, each system has a function that completes learning the first time the system is used.

- Learning completes when vehicle is driven

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Front camera system

Drive the vehicle straight ahead at 15 km/h (10 mph) or more for 1 second or more.

.gif)

- Learning completes when vehicle is operated normally

Effect/Inoperative Function When Necessary Procedures are not Performed

Necessary Procedures

Link

Power door lock control system

- Back door opener

Perform door unlock operation with door control switch or electrical key transmitter sub-assembly switch.

.gif)

Power back door system

Fully close the back door by hand.

HINT:

Initialization is not necessary if the above procedures are performed while the back door is closed.

.gif)

Air conditioning system

After the ignition switch is turned to ON, the servo motor standard position is recognized.

-

PROCEDURE

1. PRECAUTION

.png) |

NOTICE: After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal. Click here |

2. RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

Click here .gif)

3. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Click here .gif)

4. DRAIN BRAKE FLUID

.png) |

NOTICE: If brake fluid leaks onto any painted surface, immediately wash it off. |

5. REMOVE WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here .gif)

6. REMOVE NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

Click here .gif)

7. REMOVE WATER GUARD PLATE

Click here .gif)

8. REMOVE OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here .gif)

9. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

10. REMOVE DASH PANEL HEAT INSULATOR

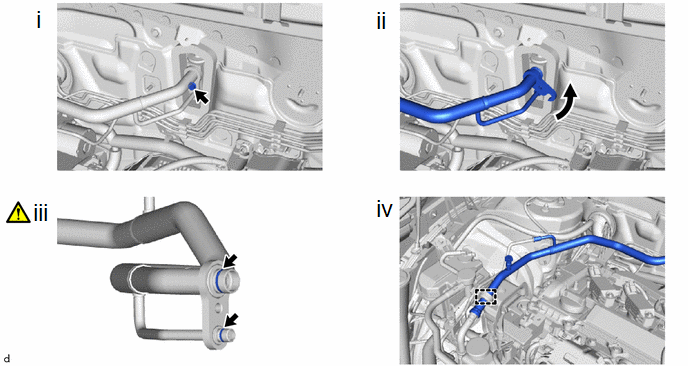

11. REMOVE AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY

(1) Remove the bolt

(2) Rotate the hook connector as shown in the illustration and disconnect the air conditioning tube and accessory assembly from the air conditioning unit assembly.

(3) Remove the 2 O-rings from the air conditioning tube and accessory assembly.

NOTICE:

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

(4) Disengage the clamp and disconnect the air conditioning tube and accessory assembly.

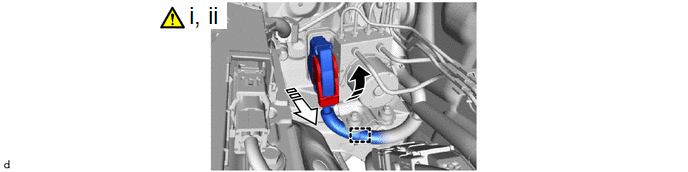

12. DISCONNECT ENGINE ROOM MAIN WIRE

.png) |

Release the lock lever |

.png) |

Disconnect the connector |

(1) Release the lock lever and disconnect the connector from the brake actuator assembly.

NOTICE:

Be careful not to allow any brake fluid to enter the connector.

(2) Disengage the clamp to separate the engine room main wire.

13. SEPARATE BRAKE LINE

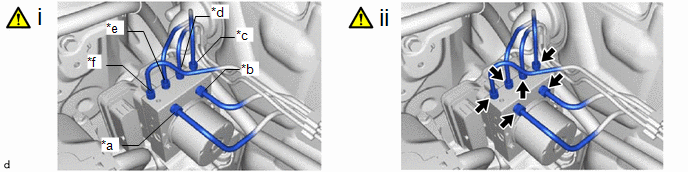

|

*a |

From 1st Chamber of Brake Master Cylinder Sub-assembly |

*b |

From 2nd Chamber of Brake Master Cylinder Sub-assembly |

|

*c |

To Front Wheel Cylinder Assembly RH |

*d |

To Rear Wheel Cylinder Assembly LH |

|

*e |

To Rear Wheel Cylinder Assembly RH |

*f |

To Front Wheel Cylinder Assembly LH |

(1) Use tags or make a memo to identify the places to reconnect the brake lines.

(2) Using a union nut wrench, disconnect the 6 brake lines from the brake actuator assembly.

NOTICE:

- Do not kink or damage the brake lines.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

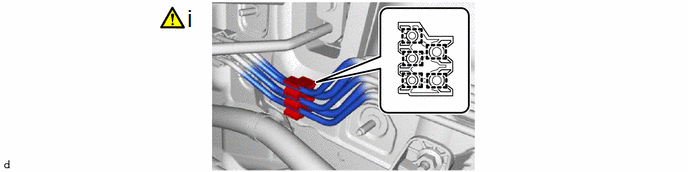

14. REMOVE NO. 3 BRAKE TUBE CLAMP

(1) Disengage the 5 clamps to remove the No. 3 brake tube clamp from the brake lines.

NOTICE:

Do not kink or damage the brake lines.

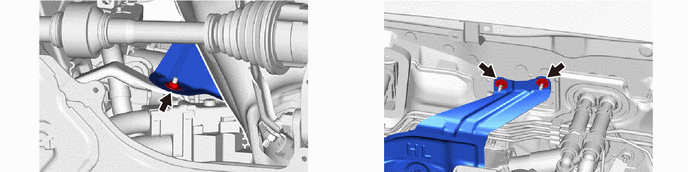

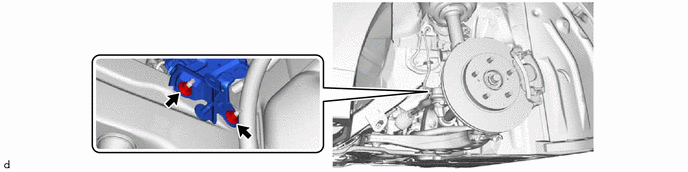

15. REMOVE BRAKE ACTUATOR WITH BRACKET

.png) |

NOTICE:

HINT: Remove the brake actuator with bracket while avoiding the brake lines. |

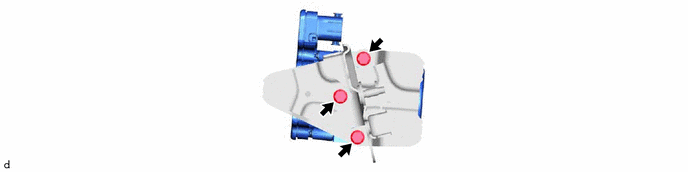

16. REMOVE BRAKE ACTUATOR ASSEMBLY

.png) |

NOTICE:

|

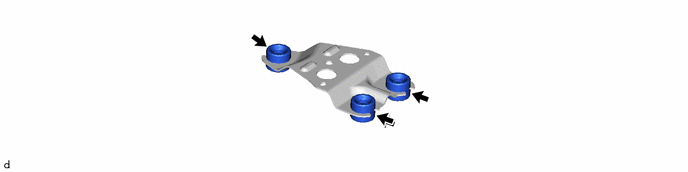

17. REMOVE NO. 1 BRAKE ACTUATOR CASE COLLAR

18. REMOVE BRAKE ACTUATOR BRACKET CUSHION