Toyota Corolla Cross: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

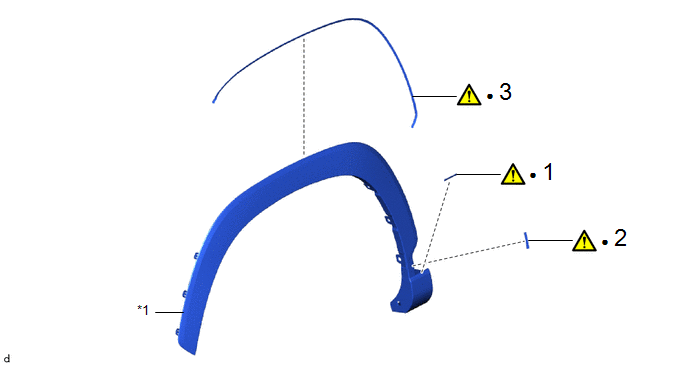

COMPONENTS (REASSEMBLY)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | NO. 5 FRONT WHEEL OPENING EXTENSION PAD |

53855B |

|

- | - |

|

2 | NO. 3 FRONT WHEEL OPENING EXTENSION PAD |

53853 |

|

- | - |

|

3 | NO. 4 FRONT WHEEL OPENING EXTENSION PAD |

53854 |

|

- | - |

|

*1 | FRONT FENDER MOULDING |

- | - |

|

● | Non-reusable part |

- | - |

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

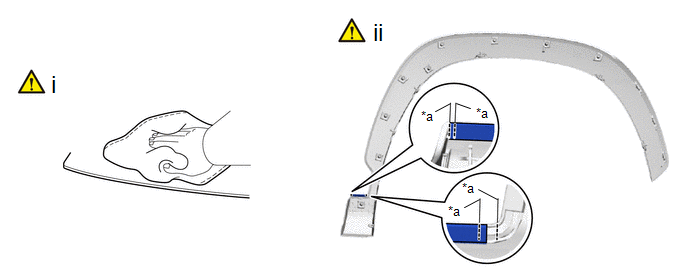

1. INSTALL NO. 5 FRONT WHEEL OPENING EXTENSION PAD

.png) |

NOTICE: When installing a new No. 5 front wheel opening extension pad, heat the front fender moulding using a heat light. |

Standard:

|

Item | Temperature |

|---|---|

|

Front Fender Moulding |

20 to 30°C (68 to 86°F) |

CAUTION:

- Do not touch the heat light and heated parts.

- Touching the heat light may result in burns.

- Touching heated parts for a long time may result in burns.

.png)

|

*a | Heated Part |

|

*b | Heat Light |

NOTICE:

Do not heat the front fender moulding excessively.

|

*a | Location Line |

- | - |

(1) Clean the front fender moulding.

1. Using a heat light, heat the front fender moulding surface.

2. Remove any remaining double-sided tape from the front fender moulding.

3. Wipe off any tape adhesive residue with cleaner.

NOTICE:

- Installing the No. 5 front wheel opening extension pad with some double-sided tape remaining may cause poor adhesion. Perform this procedure until the tape is sufficiently removed.

- Make sure to use a cloth when removing. Using a screwdriver, etc., may cause damage and poor adhesion.

(2) Install a new No. 5 front wheel opening extension pad.

1. Using a heat light, heat the front fender moulding.

2. Remove the release paper from the No. 5 front wheel opening extension pad.

HINT:

After removing the release paper, keep the exposed adhesive free from foreign matter.

3. Install the No. 5 front wheel opening extension pad as shown in the illustration.

HINT:

- Make sure that the end of the No. 5 front wheel opening extension pad is between the location lines.

- Press the No. 5 front wheel opening extension pad firmly to install it.

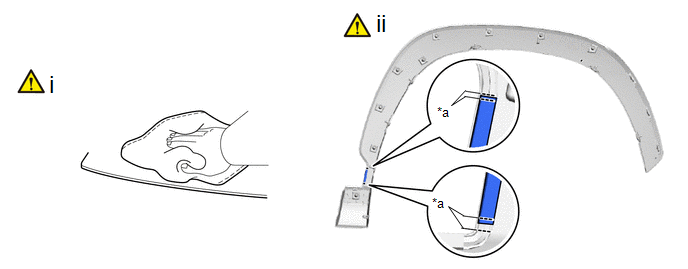

2. INSTALL NO. 3 FRONT WHEEL OPENING EXTENSION PAD

.png) |

NOTICE: When installing a new No. 3 front wheel opening extension pad, heat the front fender moulding using a heat light. |

Standard:

|

Item | Temperature |

|---|---|

|

Front Fender Moulding |

20 to 30°C (68 to 86°F) |

CAUTION:

- Do not touch the heat light and heated parts.

- Touching the heat light may result in burns.

- Touching heated parts for a long time may result in burns.

.png)

|

*a | Heated Part |

|

*b | Heat Light |

NOTICE:

Do not heat the front fender moulding excessively.

|

*a | Location Line |

- | - |

(1) Clean the front fender moulding.

1. Using a heat light, heat the front fender moulding surface.

2. Remove any remaining double-sided tape from the front fender moulding.

3. Wipe off any tape adhesive residue with cleaner.

NOTICE:

- Installing the No. 3 front wheel opening extension pad with some double-sided tape remaining may cause poor adhesion. Perform this procedure until the tape is sufficiently removed.

- Make sure to use a cloth when removing. Using a screwdriver, etc., may cause damage and poor adhesion.

(2) Install a new No. 3 front wheel opening extension pad.

1. Using a heat light, heat the front fender moulding.

2. Remove the release paper from the No. 3 front wheel opening extension pad.

HINT:

After removing the release paper, keep the exposed adhesive free from foreign matter.

3. Install the No. 3 front wheel opening extension pad as shown in the illustration.

HINT:

- Make sure that the end of the No. 3 front wheel opening extension pad is between the location lines.

- Press the No. 3 front wheel opening extension pad firmly to install it.

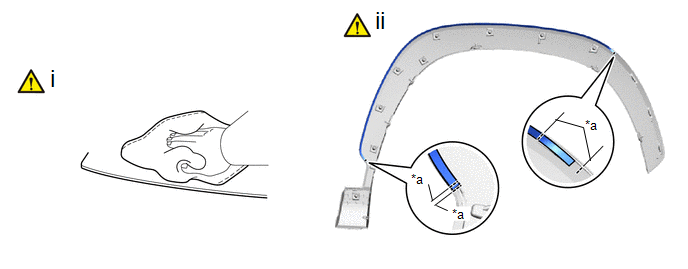

3. INSTALL NO. 4 FRONT WHEEL OPENING EXTENSION PAD

.png) |

NOTICE: When installing a new No. 4 front wheel opening extension pad, heat the front fender moulding using a heat light. |

Standard:

|

Item | Temperature |

|---|---|

|

Front Fender Moulding |

20 to 30°C (68 to 86°F) |

CAUTION:

- Do not touch the heat light and heated parts.

- Touching the heat light may result in burns.

- Touching heated parts for a long time may result in burns.

.png)

|

*a | Heated Part |

|

*b | Heat Light |

NOTICE:

Do not heat the front fender moulding excessively.

|

*a | Location Line |

- | - |

(1) Clean the front fender moulding.

1. Using a heat light, heat the front fender moulding surface.

2. Remove any remaining double-sided tape from the front fender moulding.

3. Wipe off any tape adhesive residue with cleaner.

NOTICE:

- Installing the No. 4 front wheel opening extension pad with some double-sided tape remaining may cause poor adhesion. Perform this procedure until the tape is sufficiently removed.

- Make sure to use a cloth when removing. Using a screwdriver, etc., may cause damage and poor adhesion.

(2) Install a new No. 4 front wheel opening extension pad.

1. Using a heat light, heat the front fender moulding.

2. Remove the release paper from the No. 4 front wheel opening extension pad.

HINT:

After removing the release paper, keep the exposed adhesive free from foreign matter.

3. Install the No. 4 front wheel opening extension pad as shown in the illustration.

HINT:

- Make sure that the end of the No. 4 front wheel opening extension pad is between the location lines.

- Press the No. 4 front wheel opening extension pad firmly to install it.

.gif)