Toyota Corolla Cross: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

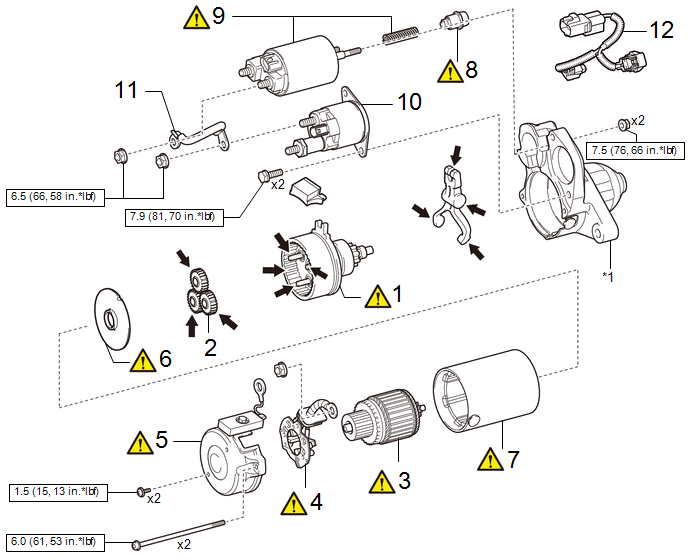

COMPONENTS (REASSEMBLY)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY |

28021 |

|

- | - |

|

2 | PLANETARY GEAR |

- | - |

- | - |

|

3 | STARTER ARMATURE ASSEMBLY |

28160 |

|

- | - |

|

4 | STARTER BRUSH HOLDER ASSEMBLY |

28140 |

|

- | - |

|

5 | STARTER COMMUTATOR END FRAME ASSEMBLY |

- |

|

- | - |

|

6 | STARTER ARMATURE PLATE |

- |

|

- | - |

|

7 | STARTER YOKE ASSEMBLY |

28120 |

|

- | - |

|

8 | PLUNGER |

- |

|

- | - |

|

9 | REPAIR SERVICE STARTER KIT |

28226B |

|

- | - |

|

10 | STARTER INRUSH CURRENT REDUCTION RELAY |

28249 | - |

- | - |

|

11 | WIRE HARNESS |

- | - |

- | - |

|

12 | HARNESS |

- | - |

- | - |

|

*1 | STARTER DRIVE HOUSING ASSEMBLY |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

.png) |

High-temperature grease |

PROCEDURE

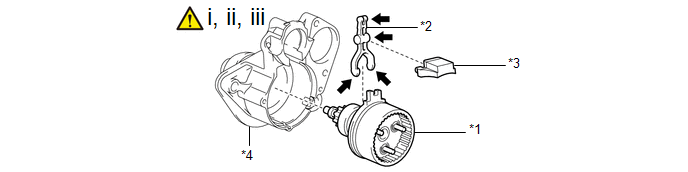

1. INSTALL STARTER CENTER BEARING CLUTCH SUB-ASSEMBLY

|

*1 | Starter Center Bearing Clutch Sub-assembly |

*2 | Pinion Drive Lever |

|

*3 | Rubber Seal |

*4 | Starter Drive Housing Assembly |

.png) |

High-temperature Grease |

- | - |

(1) Apply high-temperature grease to the pinion drive lever as shown in the illustration.

(2) Install the pinion drive lever and rubber seal to the starter center bearing clutch sub-assembly.

(3) Install the starter center bearing clutch sub-assembly together with pinion drive lever and rubber seal to the starter drive housing assembly.

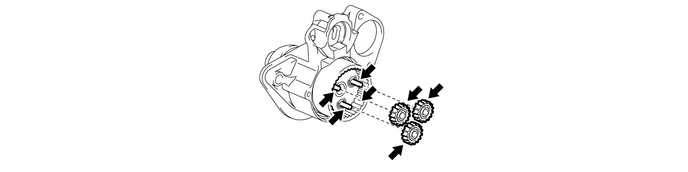

2. INSTALL PLANETARY GEAR

.png) |

High-temperature Grease | - |

- |

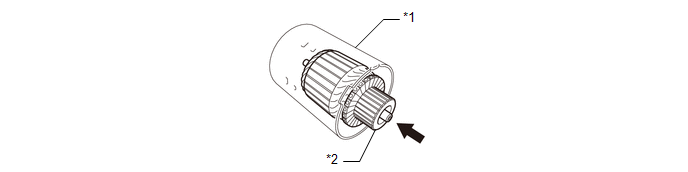

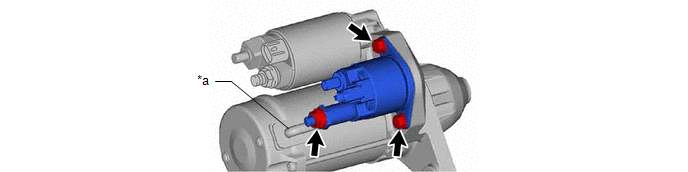

3. INSTALL STARTER ARMATURE ASSEMBLY

.png) |

NOTICE: The magnet of the starter yoke assembly may attract the starter armature assembly when the starter armature assembly is installed, causing the magnet to break. |

|

*1 | Starter Yoke Assembly |

*2 | Starter Armature Assembly |

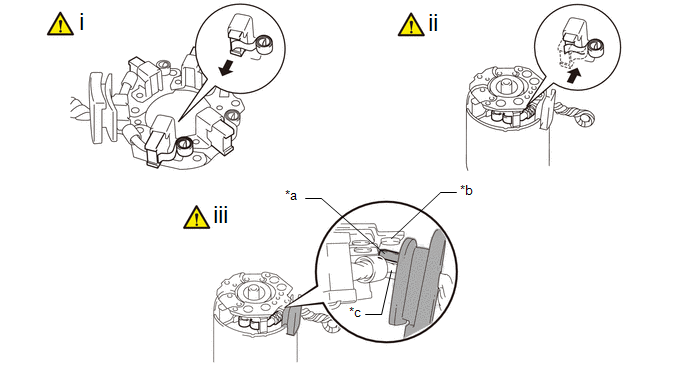

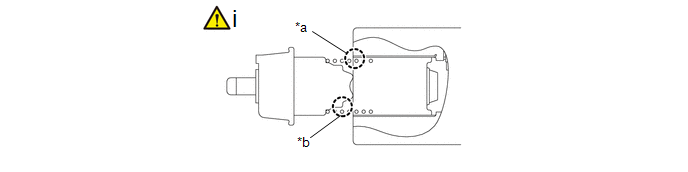

4. INSTALL STARTER BRUSH HOLDER ASSEMBLY

|

*a | Grommet |

*b | Negative (-) Brush Holder Plate |

|

*c | Positive (+) Motor Lead Wire |

- | - |

(1) Hold the brush spring back and set the 4 brushes as shown in the illustration.

(2) Install the starter brush holder assembly to the starter armature assembly and push in the 4 brushes as shown in the illustration.

(3) Fit the protrusion of the grommet between the negative (-) brush holder plate and positive (+) motor lead wire.

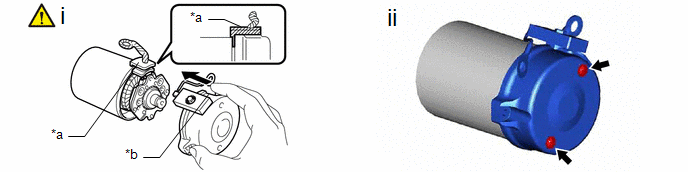

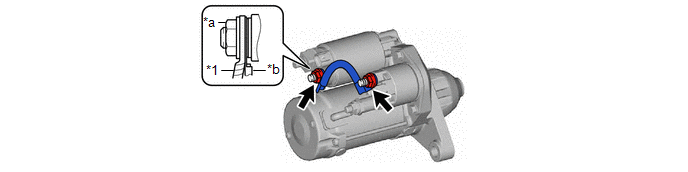

5. INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

|

*a | Lead Wire Rubber |

*b | Cutout |

(1) Install the starter commutator end frame assembly to the starter yoke assembly.

NOTICE:

Align the lead wire rubber of the starter yoke assembly with the cutout of the starter commutator end frame assembly.

(2) Install the 2 screws.

Torque:

1.5 N·m {15 kgf·cm, 13 in·lbf}

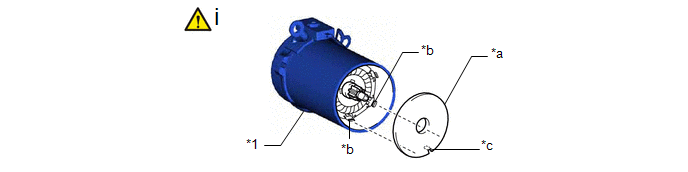

6. INSTALL STARTER ARMATURE PLATE

.png) |

NOTICE: Make sure the protrusion of the starter armature plate is inserted between the stoppers of the starter yoke assembly. |

|

*1 | Starter Yoke Assembly |

- | - |

|

*a | Starter Armature Plate |

*b | Stopper |

|

*c | Protrusion |

- | - |

(1) Align the starter armature plate so that the protrusion fits between the stoppers of the starter yoke assembly, and install the starter armature plate.

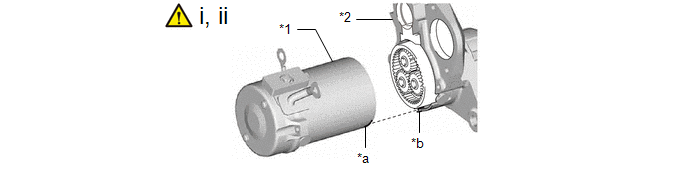

7. INSTALL STARTER YOKE ASSEMBLY

|

*1 | Starter Yoke Assembly |

*2 | Starter Drive Housing Assembly |

|

*a | Cutout |

*b | Protrusion |

(1) Align the cutout of the starter yoke assembly with the protrusion of the starter drive housing assembly.

(2) Using a T25 "TORX" socket wrench, install the 2 through bolts.

Torque:

6.0 N·m {61 kgf·cm, 53 in·lbf}

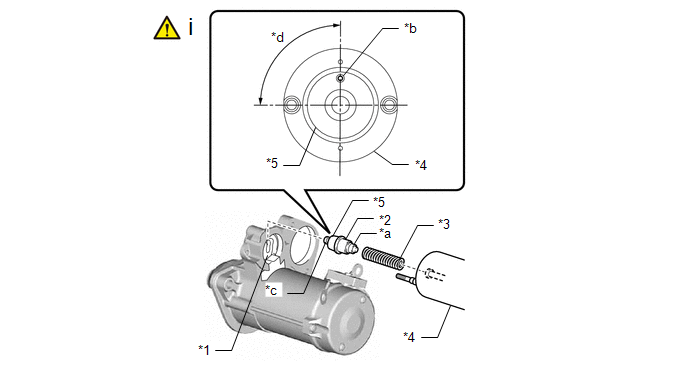

8. INSTALL PLUNGER

|

*a | Area to be Careful of Pinching |

*b | Protrusion of Plunger |

(1) Hang the hook of the plunger on the pinion drive lever and install the repair service starter kit.

NOTICE:

- Make sure the return spring is not resting on the protrusion of the plunger or pushed between the magnet switch and plunger.

- Install the plunger cover so that the ventilation hole is positioned as shown in the illustration.

9. INSTALL SERVICE STARTER KIT

|

*1 | Pinion Drive Lever |

*2 | Plunger |

|

*3 | Return Spring |

*4 | Magnet Switch |

|

*5 | Plunger Cover |

- | - |

|

*a | Protrusion |

*b | Ventilation Hole |

|

*c | Hook |

*d | 90° |

(1) Install the 2 nuts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

10. INSTALL STARTER INRUSH CURRENT REDUCTION RELAY

|

*a | Lead Wire |

- | - |

Torque:

Bolt :

7.9 N·m {81 kgf·cm, 70 in·lbf}

Nut :

9.0 N·m {92 kgf·cm, 80 in·lbf}

11. INSTALL WIRE HARNESS

|

*1 | Wire Harness |

- | - |

|

*a | Nut |

*b | Noise Filter Harness |

Torque:

6.5 N·m {66 kgf·cm, 58 in·lbf}

12. INSTALL HARNESS

.gif)