Toyota Corolla Cross: Jam Protection Function Activates During Power Back Door Operation

DESCRIPTION

When the jam protection function activates during power back door operation, one of the following may be the cause: 1) improper fit of back door, or a foreign object is stuck in the back door, 2) malfunctioning power back door sensor assembly circuit or 3) malfunctioning multiplex network door ECU.

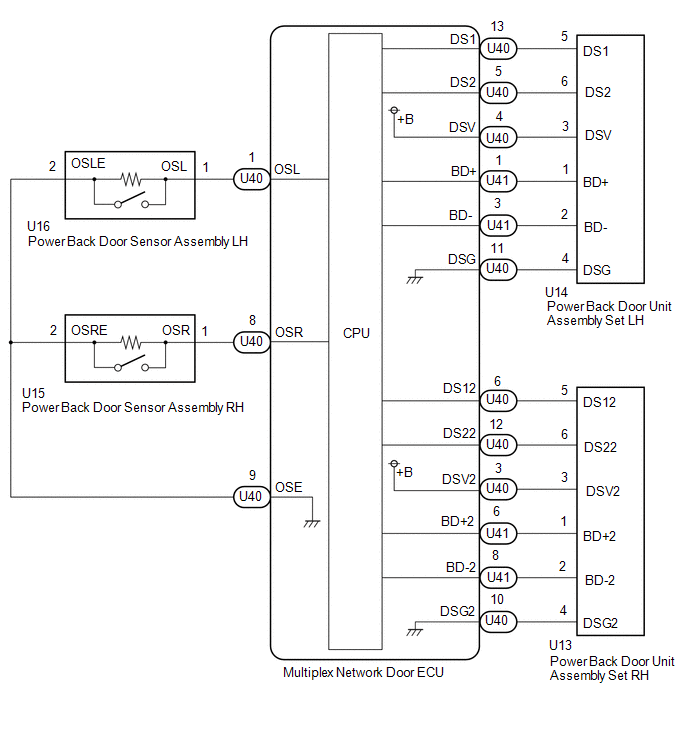

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If the replacement, removal and installation of the multiplex network door ECU or disconnection of the connectors of the multiplex network door ECU has been performed, initialize the power back door system.

Click here .gif)

PROCEDURE

| 1. |

CHECK POWER BACK DOOR SYSTEM |

(a) Check if there are any foreign objects interfering with back door operation.

| Result |

Proceed to |

|---|---|

| There are no foreign objects |

A |

| There are foreign objects |

B |

| B |

.gif) | REMOVE FOREIGN OBJECT |

|

| 2. |

CHECK BACK DOOR OPERATION |

(a) Check back door operation.

(1) Turn the main switch so that it is not pushed.

Click here

.gif)

NOTICE:

This check is possible only when the "System Settings" customization setting using the multi-information display in the combination meter assembly is set to "Off" (The default setting is "On").

(2) Open/close the back door by hand.

|

Result | Proceed to |

|---|---|

|

The back door fully opens and closes smoothly |

A |

| The back door does not fully open and close smoothly |

B |

(b) Check main switch condition.

NOTICE:

The "System Settings" customization setting using the multi-information display in the combination meter assembly is set to "On" (The default setting is "On").

(1) Turn the main switch so that it is pushed.

Click here

.gif)

| B | .gif) |

ADJUST BACK DOOR |

|

| 3. |

READ VALUE USING GTS |

(a) Check the Data List to determine if the power back door sensor assembly functions properly.

Body Electrical > Back Door > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

PBD Touch Sensor RH | Power back door sensor assembly RH signal |

ON, OFF or Open | ON: Power back door sensor assembly RH pressed OFF: Power back door sensor assembly RH not pressed Open: Power back door sensor assembly RH circuit open |

- |

| PBD Touch Sensor LH |

Power back door sensor assembly LH signal |

ON, OFF or Open | ON: Power back door sensor assembly LH pressed OFF: Power back door sensor assembly LH not pressed Open: Power back door sensor assembly LH circuit open |

- |

|

Tester Display |

|---|

| PBD Touch Sensor RH |

|

PBD Touch Sensor LH |

|

Result | Proceed to |

|---|---|

|

On the GTS screen, ON or OFF is displayed accordingly |

A |

| On the GTS screen, ON or OFF is not displayed accordingly or Open is displayed for power back door sensor assembly RH |

B |

| On the GTS screen, ON or OFF is not displayed accordingly or Open is displayed for power back door sensor assembly LH |

C |

| B |

.gif) | GO TO STEP 6 |

| C |

.gif) | GO TO STEP 8 |

|

| 4. |

REPLACE POWER BACK DOOR UNIT ASSEMBLY SET |

(a) Temporarily replace the power back door unit assembly set with a new or normally functioning one.

Click here .gif)

|

| 5. |

CHECK POWER BACK DOOR SYSTEM |

(a) Check power back door system operation.

Click here .gif)

.gif)

OK:

Power back door system operates normally.

| OK | .gif) | END (POWER BACK DOOR UNIT ASSEMBLY SET WAS DEFECTIVE) |

| NG | .gif) | REPLACE MULTIPLEX NETWORK DOOR ECU |

| 6. |

INSPECT POWER BACK DOOR SENSOR ASSEMBLY RH |

Click here .gif)

| NG | .gif) | REPLACE POWER BACK DOOR SENSOR ASSEMBLY RH |

|

| 7. |

CHECK HARNESS AND CONNECTOR (POWER BACK DOOR SENSOR ASSEMBLY RH - MULTIPLEX NETWORK DOOR ECU) |

(a) Disconnect the U15 power back door sensor assembly RH connector.

(b) Disconnect the U40 multiplex network door ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U15-1 (OSR) - U40-8 (OSR) |

Always | Below 1 Ω |

|

U15-2 (OSRE) - U40-9 (OSE) |

Always | Below 1 Ω |

|

U15-1 (OSR) or U40-8 (OSR) - Body ground |

Always | 10 kΩ or higher |

|

U15-2 (OSRE) or U40-9 (OSE) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MULTIPLEX NETWORK DOOR ECU |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

| 8. |

INSPECT POWER BACK DOOR SENSOR ASSEMBLY LH |

Click here .gif)

| NG | .gif) | REPLACE POWER BACK DOOR SENSOR ASSEMBLY LH |

|

| 9. |

CHECK HARNESS AND CONNECTOR (POWER BACK DOOR SENSOR ASSEMBLY LH - MULTIPLEX NETWORK DOOR ECU) |

(a) Disconnect the U16 power back door sensor assembly LH connector.

(b) Disconnect the U40 multiplex network door ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U16-1 (OSL) - U40-1 (OSL) |

Always | Below 1 Ω |

|

U16-2 (OSLE) - U40-9 (OSE) |

Always | Below 1 Ω |

|

U16-1 (OSL) or U40-1 (OSL) - Body ground |

Always | 10 kΩ or higher |

|

U16-2 (OSLE) or U40-9 (OSE) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MULTIPLEX NETWORK DOOR ECU |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)