Toyota Corolla Cross: Reassembly

REASSEMBLY

CAUTION / NOTICE / HINT

COMPONENTS (REASSEMBLY)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

FRONT DRIVE SHAFT BEARING |

43410C |

|

- |

- |

|

2 |

FRONT DRIVE SHAFT DUST COVER |

41336D |

|

- |

- |

|

3 |

FRONT AXLE OUTBOARD JOINT BOOT |

- |

|

- |

- |

|

4 |

FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP |

43447F |

|

- |

- |

|

5 |

FRONT AXLE OUTBOARD JOINT BOOT CLAMP |

43447E |

|

- |

- |

|

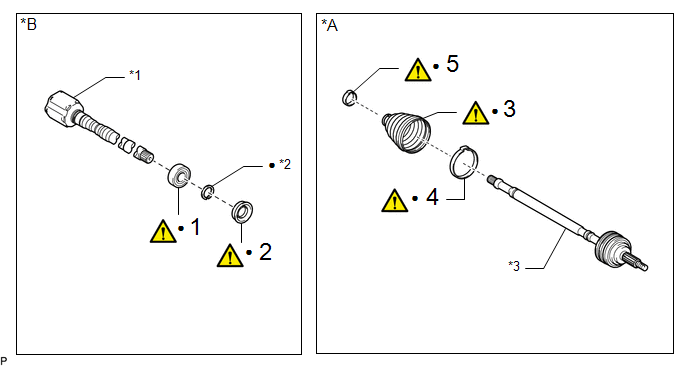

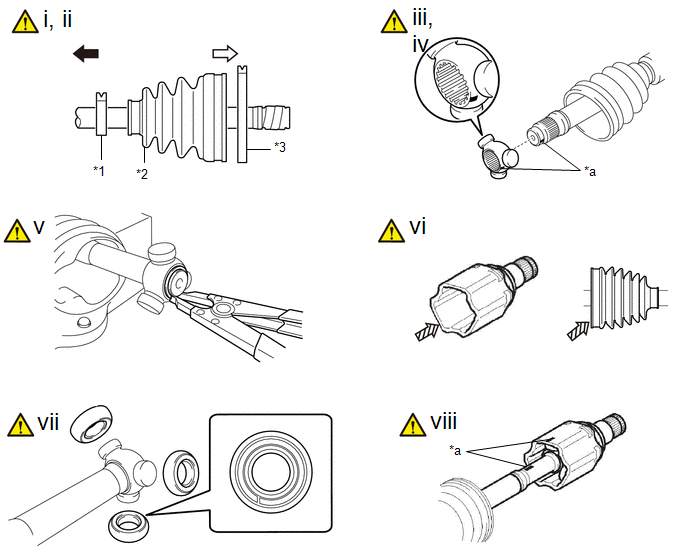

*A |

for LH Side |

*B |

for RH Side |

|

*1 |

FRONT DRIVE INBOARD JOINT ASSEMBLY |

*2 |

SNAP RING |

|

*3 |

FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

- |

- |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

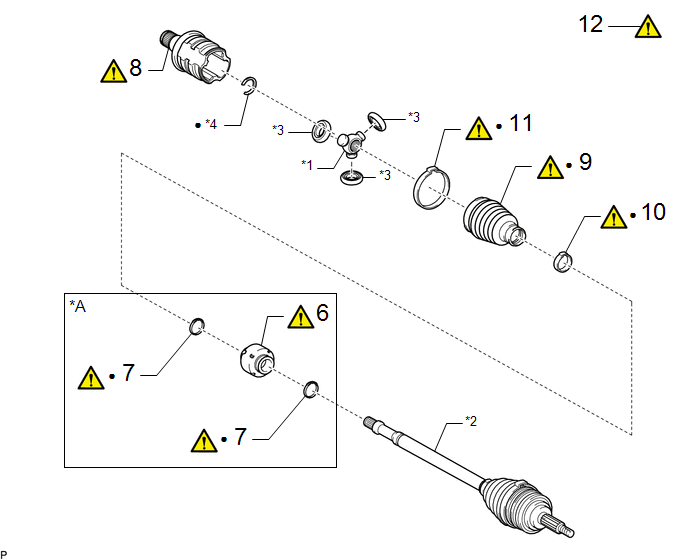

6 |

FRONT DRIVE SHAFT DAMPER |

43474E |

|

- |

- |

|

7 |

FRONT DRIVE SHAFT DAMPER CLAMP |

43474G |

|

- |

- |

|

8 |

FRONT DRIVE INBOARD JOINT ASSEMBLY |

- |

|

- |

- |

|

9 |

FRONT AXLE INBOARD JOINT BOOT |

- |

|

- |

- |

|

10 |

FRONT AXLE INBOARD JOINT BOOT CLAMP |

43448F |

|

- |

- |

|

11 |

FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP |

43448G |

|

- |

- |

|

12 |

INSPECT FRONT DRIVE SHAFT ASSEMBLY |

43420 |

|

- |

- |

|

*A |

for LH Side |

- |

- |

|

*1 |

TRIPOD JOINT |

*2 |

FRONT DRIVE OUTBOARD JOINT SHAFT ASSEMBLY |

|

*3 |

ROLLER |

*4 |

SHAFT SNAP RING |

|

● |

Non-reusable part |

- |

- |

CAUTION / NOTICE / HINT

NOTICE:

- Secure the drive shaft in a vise between aluminum plates.

- Do not overtighten the vise.

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

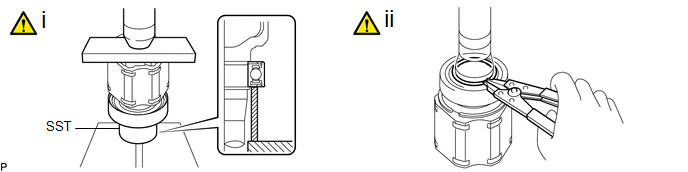

1. INSTALL FRONT DRIVE SHAFT BEARING (for RH Side)

(1) Using SST, a steel plate and a press, press in the front drive inboard joint assembly until a new front drive shaft bearing contacts the edge of the front drive inboard joint assembly.

SST: 09710-30012

09710-04061

NOTICE:

- Make sure the front drive shaft bearing contacts the edge of the front drive inboard joint assembly, but do not press it in more than necessary.

- Do not apply weight to the dust cover and outer race of the front drive shaft bearing.

(2) Using a snap ring expander, install a new snap ring.

NOTICE:

The snap ring should be installed completely.

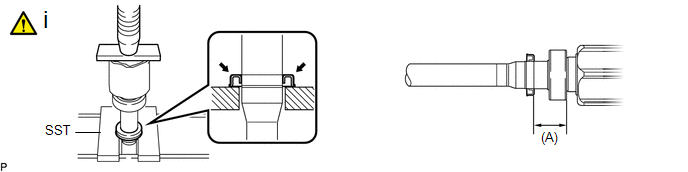

2. INSTALL FRONT DRIVE SHAFT DUST COVER (for RH Side)

(1) Using SST, a steel plate and a press, install a new front drive shaft dust cover to the front drive inboard joint assembly until the distance from the tip of the front drive inboard joint assembly to the front drive shaft dust cover reaches the specification as shown in the illustration.

SST: 09527-10011

Standard Distance (A):

87.7 to 88.3 mm (3.45 to 3.48 in.)

NOTICE:

- Make sure to install the front drive shaft dust cover in the correct direction.

- Do not damage the front drive shaft dust cover.

3. INSTALL FRONT AXLE OUTBOARD JOINT BOOT (for LH Side)

.png)

|

*1 |

Front Drive Outboard Joint Shaft Assembly |

*2 |

Front No. 2 Axle Outboard Joint Boot Clamp |

|

*3 |

Front Axle Outboard Joint Boot |

*4 |

Front Axle Outboard Joint Boot Clamp |

.png) |

Outboard Joint Side |

.png) |

Inboard Joint Side |

.png) |

Grease |

- |

- |

(1) Wrap the splines of the front drive outboard joint shaft assembly with protective tape to prevent the boot from being damaged.

(2) Install new parts to the front drive outboard joint shaft assembly in the following order:

1. Front No. 2 axle outboard joint boot clamp

2. Front axle outboard joint boot

3. Front axle outboard joint boot clamp

(3) Pack the joint portion of the front drive outboard joint shaft assembly and front axle outboard joint boot with grease.

Standard Grease Capacity:

90 to 110 g (3.17 to 3.88 oz.)

(4) Install the front axle outboard joint boot to the front drive outboard joint shaft assembly groove.

NOTICE:

- Do not allow grease to adhere to the boot clamp track of the outboard joint boot.

- Keep the inside of the outboard joint boot free of foreign matter.

4. INSTALL FRONT NO. 2 AXLE OUTBOARD JOINT BOOT CLAMP (for LH Side)

.png)

|

*a |

Hold |

- |

- |

.png) |

Turn |

- |

- |

(1) Install the front No. 2 axle outboard joint boot clamp to the front axle outboard joint boot.

(2) Place SST onto the front No. 2 axle outboard joint boot clamp, press it against the boot and slightly tighten SST.

SST: 09521-24010

(3) Tighten SST so that the front No. 2 axle outboard joint boot clamp is pinched.

NOTICE:

Do not overtighten SST.

(4) Using SST, measure the clearance of the front No. 2 axle outboard joint boot clamp.

SST: 09240-00021

Clearance:

1.2 to 4.0 mm (0.0472 to 0.158 in.)

(5) If the clearance is not as specified, retighten SST.

5. INSTALL FRONT AXLE OUTBOARD JOINT BOOT CLAMP (for LH Side)

(a) Use the same procedure described for the front No. 2 axle outboard joint boot clamp.

6. INSTALL FRONT DRIVE SHAFT DAMPER (for LH Side)

.png)

|

*1 |

Front Drive Shaft Damper |

*2 |

Front Drive Shaft Damper Clamp |

(1) Temporarily install the front drive shaft damper and 2 new front drive shaft damper clamps to the front drive outboard joint shaft assembly as shown in the illustration.

(2) Set the dimension (A) as specified below.

Dimension (A):

188.4 to 192.4 mm (7.42 to 7.57 in.)

7. INSTALL FRONT DRIVE SHAFT DAMPER CLAMP (for LH Side)

HINT:

Use the same procedure for each front drive shaft damper clamp.

.png)

(1) Using needle-nose pliers, install the 2 front drive shaft damper clamps as shown in the illustration.

NOTICE:

- Be sure to install the clamps in the correct position.

- Do not damage the front drive shaft damper.

8. INSTALL FRONT DRIVE INBOARD JOINT ASSEMBLY

|

*1 |

Front Axle Inboard Joint Boot Clamp |

*2 |

Front Axle Inboard Joint Boot |

|

*3 |

Front No. 2 Axle Inboard Joint Boot Clamp |

- |

- |

|

*a |

Matchmark |

- |

- |

.png) |

Outboard Joint Side |

.png) |

Inboard Joint Side |

.png) |

Grease |

- |

- |

(1) Install new parts to the front drive outboard joint shaft assembly in the following order:

1. Front axle inboard joint boot clamp

2. Front axle inboard joint boot

3. Front No. 2 axle inboard joint boot clamp

(2) Remove the protective tape.

(3) Align the matchmarks and install the tripod joint to the front drive outboard joint shaft assembly.

NOTICE:

Face the serrated side of the tripod joint outward and install it to the outboard joint end.

(4) Using a brass bar and a hammer, install the tripod joint to the front drive outboard joint shaft assembly.

NOTICE:

- Keep the tripod joint free of foreign matter.

- Be sure to install the tripod joint in the correct direction.

(5) Using a snap ring expander, install a new shaft snap ring to the front drive outboard joint shaft assembly.

(6) Pack the front drive inboard joint assembly and front axle inboard joint boot with grease.

Standard Grease Capacity:

170 to 190 g (6.00 to 6.70 oz.)

(7) Install the 3 rollers to the tripod joint.

NOTICE:

- Make sure to install the rollers in the correct direction as shown in the illustration.

- Do not drop the rollers.

(8) Align the matchmarks and install the front drive inboard joint assembly to the front drive outboard joint shaft assembly.

9. INSTALL FRONT AXLE INBOARD JOINT BOOT

|

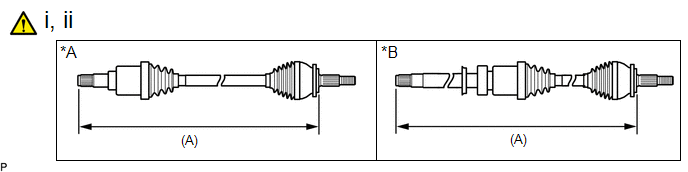

*A |

for LH Side |

*B |

for RH Side |

(1) Install the front axle inboard joint boot to the front drive inboard joint assembly.

NOTICE:

- Keep the grooves free of grease.

- Keep the inside of the front axle inboard joint boot free of foreign matter.

(2) Check whether the drive shaft dimension (A) is within specification.

Dimension (A):

|

for LH Side |

590.9 mm (1.94 ft.) |

|

for RH Side |

891.0 mm (2.92 ft.) |

10. INSTALL FRONT AXLE INBOARD JOINT BOOT CLAMP

.png)

|

*a |

Hold |

- |

- |

.png) |

Turn |

- |

- |

(1) Place SST onto the front axle inboard joint boot clamp, press it against the boot and slightly tighten SST.

SST: 09521-24010

(2) Tighten SST so that the front axle inboard joint boot clamp is pinched.

NOTICE:

Do not overtighten SST.

(3) Using SST, measure the clearance of the front axle inboard joint boot clamp.

SST: 09240-00021

Clearance:

1.2 to 4.0 mm (0.0472 to 0.158 in.)

(4) If the clearance is not as specified, retighten SST.

11. INSTALL FRONT NO. 2 AXLE INBOARD JOINT BOOT CLAMP

(a) Use the same procedure described for the front axle inboard joint boot clamp.

12. INSPECT FRONT DRIVE SHAFT ASSEMBLY

Click here .gif)