Toyota Corolla Cross: Oil Pressure Sensor

Removal

REMOVAL

CAUTION / NOTICE / HINT

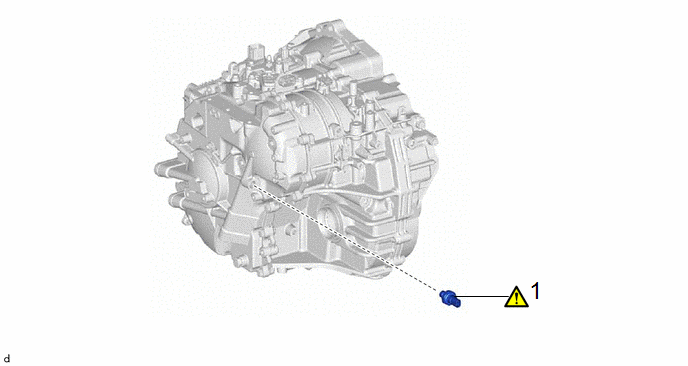

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

OIL PRESSURE SENSOR |

89637K |

|

- |

- |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the oil pressure sensor removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effect/Inoperative Function When Necessary Procedures are not Performed |

Link |

|---|---|---|---|

|

Oil pressure sensor |

|

Deterioration of fuel efficiency |

|

PROCEDURE

1. REMOVE OIL PRESSURE SENSOR

(1) Disconnect the oil pressure sensor connector.

(2) Using a 27 mm deep socket wrench, remove the oil pressure sensor from the rear transaxle case sub-assembly.

Installation

INSTALLATION

CAUTION / NOTICE / HINT

.png)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

OIL PRESSURE SENSOR |

89637K |

|

- |

- |

|

2 |

INSPECT FOR CONTINUOUSLY VARIABLE TRANSAXLE FLUID LEAK |

- |

|

- |

- |

|

3 |

RESET MEMORY |

- |

- |

- |

|

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

.png) |

Toyota Genuine CVT Fluid FE |

PROCEDURE

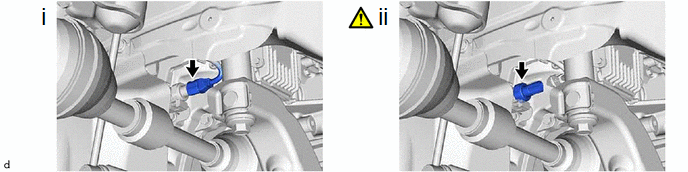

1. INSTALL OIL PRESSURE SENSOR

.png)

.png) |

Toyota Genuine CVT fluid FE |

- |

- |

(1) Coat the O-ring of the oil pressure sensor with Toyota Genuine CVT fluid FE.

NOTICE:

If reusing the oil pressure sensor, check that the O-ring is not damaged.

(2) Using a 27 mm deep socket wrench, install the oil pressure sensor to the rear transaxle case sub-assembly.

Torque:

20.6 N·m {210 kgf·cm, 15 ft·lbf}

NOTICE:

Be careful not to damage the O-ring.

(3) Connect the oil pressure sensor connector.

2. INSPECT FOR CONTINUOUSLY VARIABLE TRANSAXLE FLUID LEAK

Click here .gif)

3. RESET MEMORY

NOTICE:

If continuously variable transaxle parts have been replaced, refer to Parts Replacement Compensation Table to determine if any additional operations are necessary.

Click here .gif)

.gif)

.gif)