Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

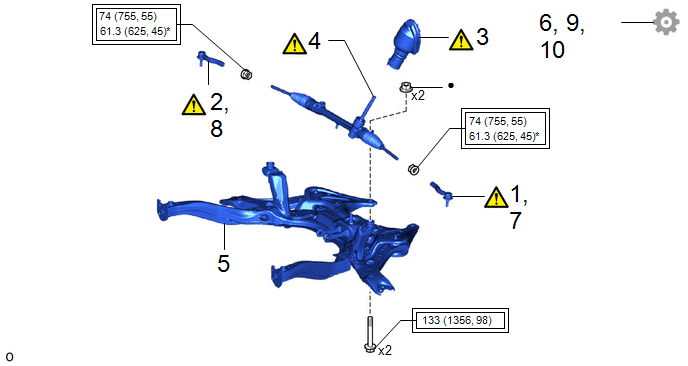

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

TEMPORARILY TIGHTEN TIE ROD END SUB-ASSEMBLY LH |

45047 |

|

- |

- |

|

2 |

TEMPORARILY TIGHTEN TIE ROD END SUB-ASSEMBLY RH |

45046 |

|

- |

- |

|

3 |

NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY |

45025D |

|

- |

- |

|

4 |

STEERING LINK ASSEMBLY |

- |

|

- |

- |

|

5 |

FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY |

51201F |

- |

- |

- |

|

6 |

INSPECT AND ADJUST FRONT WHEEL ALIGNMENT |

- |

- |

- |

|

|

7 |

FULLY TIGHTEN TIE ROD END SUB-ASSEMBLY LH |

45047 |

|

- |

- |

|

8 |

FULLY TIGHTEN TIE ROD END SUB-ASSEMBLY RH |

45046 |

|

- |

- |

|

9 |

PERFORM END POSITION INITIAL SETTING |

- |

- |

- |

|

|

10 |

PERFORM INITIALIZATION |

- |

- |

- |

|

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

|

* |

For use with SST |

- |

- |

PROCEDURE

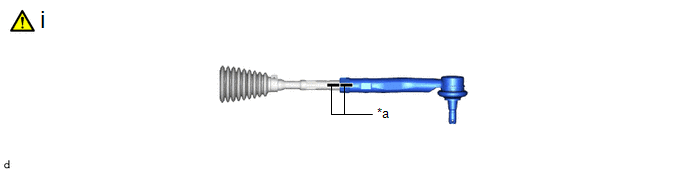

1. TEMPORARILY TIGHTEN TIE ROD END SUB-ASSEMBLY LH

|

*a |

Matchmark |

- |

- |

(1) Temporarily install the lock nut and tie rod end sub-assembly LH to the steering gear assembly until the matchmarks are aligned.

HINT:

After adjusting the toe-in, tighten the lock nut.

2. TEMPORARILY TIGHTEN TIE ROD END SUB-ASSEMBLY RH

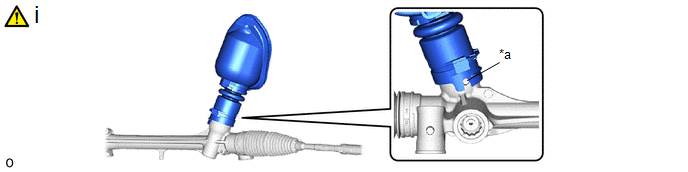

3. INSTALL NO. 1 STEERING COLUMN HOLE COVER SUB-ASSEMBLY

|

*a |

Protrusion |

- |

- |

(1) Align the protrusion of the steering link assembly with the hole of the No. 1 steering column hole cover sub-assembly, and install the No. 1 steering column hole cover sub-assembly to the steering link assembly.

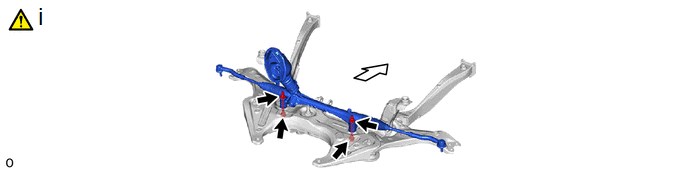

4. INSTALL STEERING LINK ASSEMBLY

.png) |

Front of the Vehicle |

- |

- |

(1) Install the steering link assembly to the front suspension crossmember sub-assembly with the 2bolts and 2 new nuts.

Torque:

133 N·m {1356 kgf·cm, 98 ft·lbf}

NOTICE:

- Because the nut has its own stopper, do not turn the nut. Tighten the bolt with the nut secured.

- Make sure to tighten the bolts starting from the right side of the vehicle.

5. INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

Click here .gif)

6. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

Click here .gif)

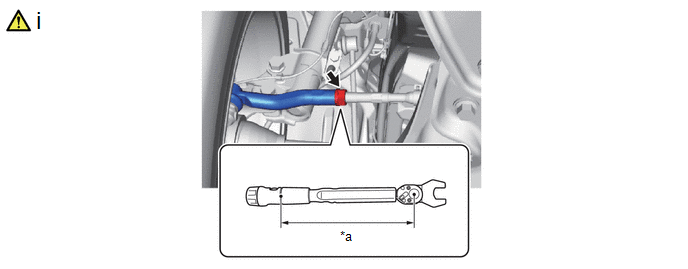

7. FULLY TIGHTEN TIE ROD END SUB-ASSEMBLY LH

|

*a |

Torque Wrench Fulcrum Length |

- |

- |

(1) Using SST, tighten the tie rod end sub-assembly lock nut.

SST: 09612-24014

09617-24011

Torque:

Specified Tightening Torque :

74 N·m {755 kgf·cm, 55 ft·lbf}

HINT:

- Calculate the torque wrench reading when changing the fulcrum length of

the torque wrench.

Click here

.gif)

- When using SST (fulcrum length of 52.7 mm (2.07 in.)) + torque wrench (fulcrum length of 255 mm (10.04 in.)): 61.3 N*m (625 kgf*cm, 45 ft.*lbf)

8. FULLY TIGHTEN TIE ROD END SUB-ASSEMBLY RH

9. PERFORM END POSITION INITIAL SETTING

Click here .gif)

10. PERFORM INITIALIZATION

- Parking Assist Monitor System:

Click here

.gif)

- Automatic headlight beam level control system:

Click here

.gif)