Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

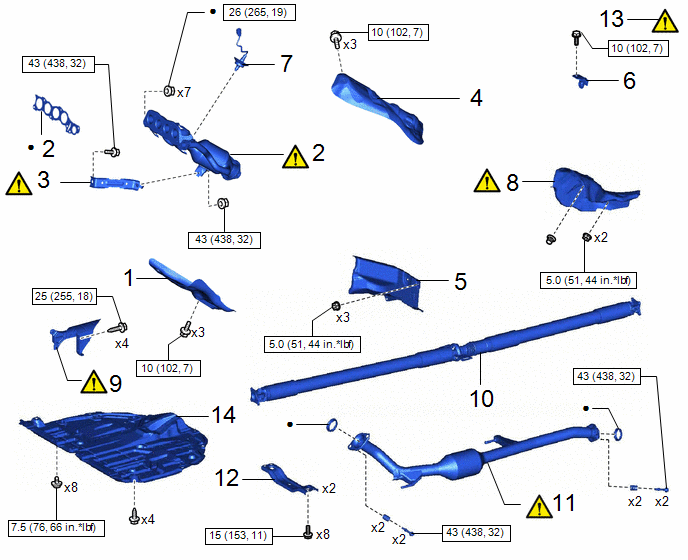

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | NO. 2 EXHAUST MANIFOLD HEAT INSULATOR |

17168 | - |

- | - |

|

2 | EXHAUST MANIFOLD (TWC: Front Catalyst) |

17141 |

- | - | |

|

3 | MANIFOLD STAY |

17118 |

- | - | |

|

4 | NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

17167 |

- | - | |

|

5 | DASH PANEL HEAT INSULATOR |

55225C | - |

- | - |

|

6 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

7 | AIR FUEL RATIO SENSOR |

89467B | - |

- | - |

|

8 | FRONT NO. 1 FLOOR HEAT INSULATOR |

58151 | - |

- | - |

|

9 | PROPELLER SHAFT HEAT INSULATOR |

37117B | - |

- | - |

|

10 | PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY |

37100 | - |

- | - |

|

11 | FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst) |

17410 |

- | - | |

|

12 | FRONT FLOOR CENTER BRACE |

57533B | - |

- | - |

|

13 | INSPECT FOR EXHAUST GAS LEAK |

- |

- | - | |

|

14 | NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 | - |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

PROCEDURE

1. INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

2. INSTALL EXHAUST MANIFOLD (TWC: Front Catalyst)

.png)

(1) Install a new exhaust manifold to head gasket to the cylinder head sub-assembly.

(2) Using a 12 mm deep socket wrench, temporarily install the exhaust manifold (TWC: Front Catalyst) to the cylinder head sub-assembly with 7 new nuts.

(3) Using the 12 mm deep socket wrench, tighten the 7 nuts in the order shown in the illustration.

Torque:

26 N·m {265 kgf·cm, 19 ft·lbf}

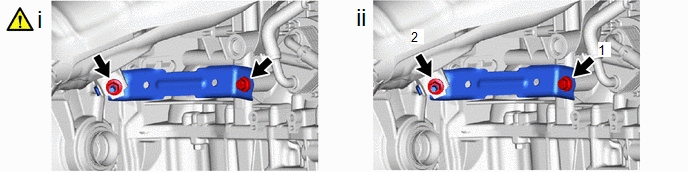

3. INSTALL MANIFOLD STAY

(1) Temporarily install the manifold stay to the exhaust manifold (TWC: Front Catalyst) and cylinder block sub-assembly with the bolt and nut.

(2) Tighten the bolt and nut in the order shown in the illustration.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

4. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

5. INSTALL DASH PANEL HEAT INSULATOR

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

6. INSTALL WIRE HARNESS CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

7. INSTALL AIR FUEL RATIO SENSOR

Click here .gif)

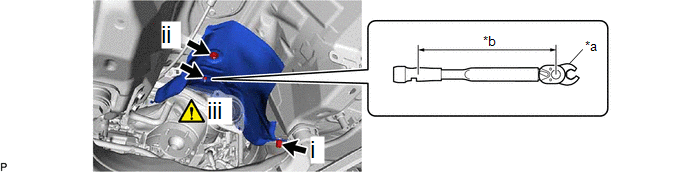

8. INSTALL FRONT NO. 1 FLOOR HEAT INSULATOR

|

*a | 10 mm Union Nut Wrench |

*b | Torque Wrench Fulcrum Length |

(1) Install the clip.

(2) Install the nut.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

(3) Using a 10 mm union nut wrench, Install the No. 1 exhaust manifold heat insulator with the nut.

Torque:

Specified tightening torque :

5.0 N·m {51 kgf·cm, 44 in·lbf}

HINT:

- Calculate the torque wrench reading when changing the fulcrum length of the torque wrench

Click here

.gif)

.gif)

- When using a union nut wrench (fulcrum length of 22 mm (0.866 in.)) + torque wrench (fulcrum length of 162 mm (6.38 in.)): 4.4 N*m (44 kgf*cm, 38 in.*lbf)

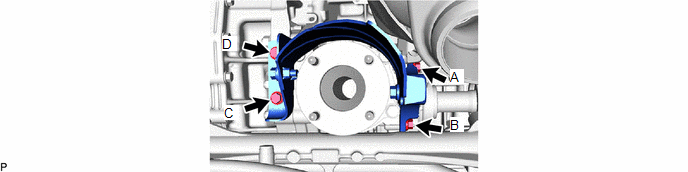

9. INSTALL PROPELLER SHAFT HEAT INSULATOR

(1) Install the propeller shaft heat insulator with the 4 bolts.

Torque:

25 N·m {255 kgf·cm, 18 ft·lbf}

NOTICE:

Temporarily install the bolt (A), and then tighten the 4 bolts in the order of (B), (A), (D) and (C).

10. INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

Click here

.gif)

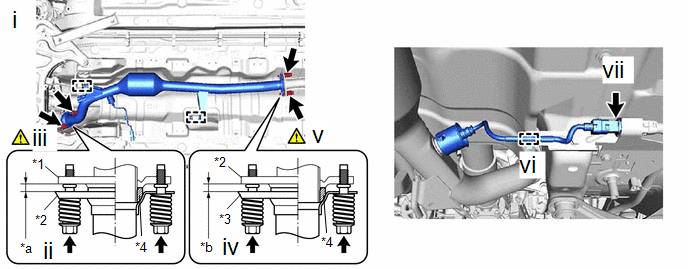

11. INSTALL FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

.png)

|

*1 | Exhaust Manifold (TWC: Front Catalyst) or Front Exhaust Pipe Assembly (TWC: Rear Catalyst) |

*2 | Gasket |

|

*a | Wooden Block |

*b | Plastic Hammer |

(1) Using a vernier caliper, measure the free length of the compression springs.

|

Standard Length (Front) | 43 mm (1.69 in.) |

|

Standard Length (Rear) |

40 mm (1.57 in.) |

|

Minimum Free Length (Front) |

41.5 mm (1.63 in.) |

|

Minimum Free Length (Rear) |

38.5 mm (1.52 in.) |

If the free length is less than the minimum, replace the compression spring.

(2) temporarily install 2 new gaskets to the exhaust manifold (TWC: Front Catalyst) and front exhaust pipe assembly (TWC: Rear Catalyst).

(3) Using a plastic hammer and wooden block, tap in each gasket until its surface is flush with the exhaust manifold (TWC: Front Catalyst) and front exhaust pipe assembly (TWC: Rear Catalyst).

NOTICE:

- Be sure to install the gasket in the correct direction.

- Do not reuse the gaskets.

- Do not damage the gaskets.

- Do not push in the gaskets by using the exhaust pipes when connecting them.

|

*1 | Exhaust Manifold (TWC: Front Catalyst) |

*2 | Front Exhaust Pipe Assembly (TWC: Rear Catalyst) |

|

*3 | Tail Exhaust Pipe Assembly |

*4 | Gasket |

|

*a | Space between Flanges: 8.5 mm (0.335in.) |

*b | Space between Flanges: 6.5 mm (0.256in.) |

(1) Connect the front exhaust pipe assembly to the 2 exhaust pipe supports.

(2) Install the front exhaust pipe assembly (TWC: Rear Catalyst) to the exhaust manifold (TWC: Front Catalyst) with the 2 compression springs and 2 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

(3) After installation, check that the space between the flanges of the exhaust manifold (TWC: Front Catalyst) and front exhaust pipe assembly (TWC: Rear Catalyst) is consistent front-to-rear and left-to-right.

(4) Install the front exhaust pipe assembly (TWC: Rear Catalyst) to the tail exhaust pipe assembly with the 2 compression springs and 2 bolts.

Torque:

43 N·m {438 kgf·cm, 32 ft·lbf}

(5) After installation, check that the space between the flanges of the front exhaust pipe assembly (TWC: Rear Catalyst) and tail exhaust pipe assembly is consistent front-to-rear and left-to-right.

(6) Engage the wire harness clamp.

(7) Connect the heated oxygen sensor connector.

12. INSTALL FRONT FLOOR CENTER BRACE

Torque:

15 N·m {153 kgf·cm, 11 ft·lbf}

13. INSPECT FOR EXHAUST GAS LEAK

Click here

.gif)

14. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)