Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

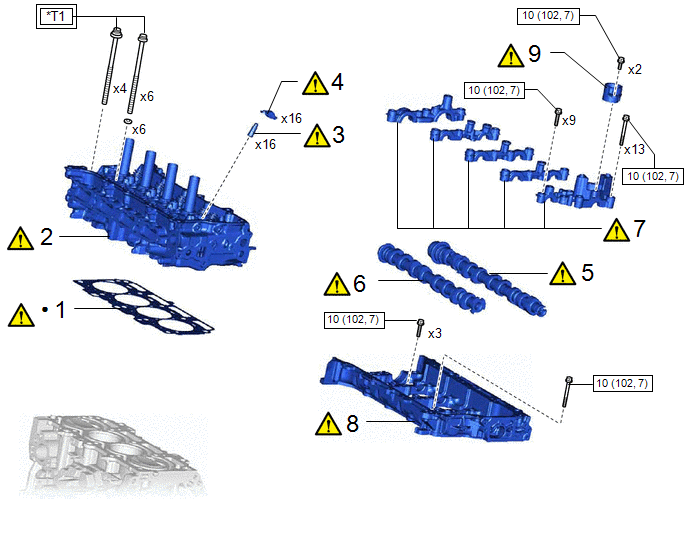

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | CYLINDER HEAD GASKET |

11115 |

|

- | - |

|

2 | CYLINDER HEAD SUB-ASSEMBLY |

11101 |

|

- | - |

|

3 | VALVE LASH ADJUSTER ASSEMBLY |

13750 |

|

- | - |

|

4 | NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

13801 |

|

- | - |

|

5 | EXHAUST CAMSHAFT SUB-ASSEMBLY |

13502B |

|

- | - |

|

6 | INTAKE CAMSHAFT SUB-ASSEMBLY |

13501A |

|

- | - |

|

7 | CAMSHAFT BEARING CAP |

- |

|

- | - |

|

8 | CAMSHAFT HOUSING SUB-ASSEMBLY |

11103 |

|

- | - |

|

9 | FUEL PUMP LIFTER GUIDE |

23477 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

|

*T1 | 1st: 50 (510, 37) 2nd: Turn 90° 3rd: Turn 90° |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

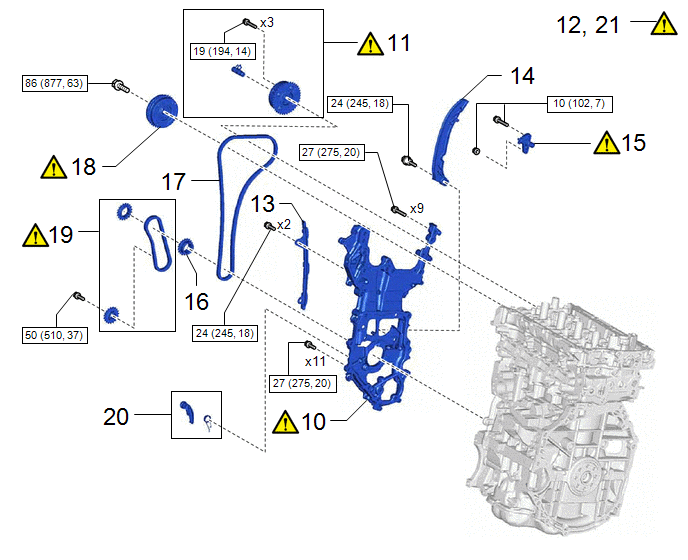

10 | TIMING CHAIN COVER ASSEMBLY |

11310 |

|

- | - |

|

11 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

13070A |

|

- | - |

|

12 | NO. 1 CYLINDER TO TDC (COMPRESSION) |

- |

|

- | - |

|

13 | NO. 1 CHAIN VIBRATION DAMPER |

13561 | - |

- | - |

|

14 | CHAIN TENSIONER SLIPPER |

13559 | - |

- | - |

|

15 | NO. 1 CHAIN TENSIONER ASSEMBLY |

13540 |

|

- | - |

|

16 | CRANKSHAFT TIMING SPROCKET |

13521 | - |

- | - |

|

17 | CHAIN SUB-ASSEMBLY |

13506 | - |

- | - |

|

18 | CAMSHAFT TIMING GEAR ASSEMBLY |

13050 |

|

- | - |

|

19 | OIL PUMP DRIVE CHAIN SUB-ASSEMBLY |

13507A |

|

- | - |

|

20 | CHAIN TENSIONER PLATE |

13549A | - |

- | - |

|

21 | NO. 1 CYLINDER TO TDC (COMPRESSION) |

- |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

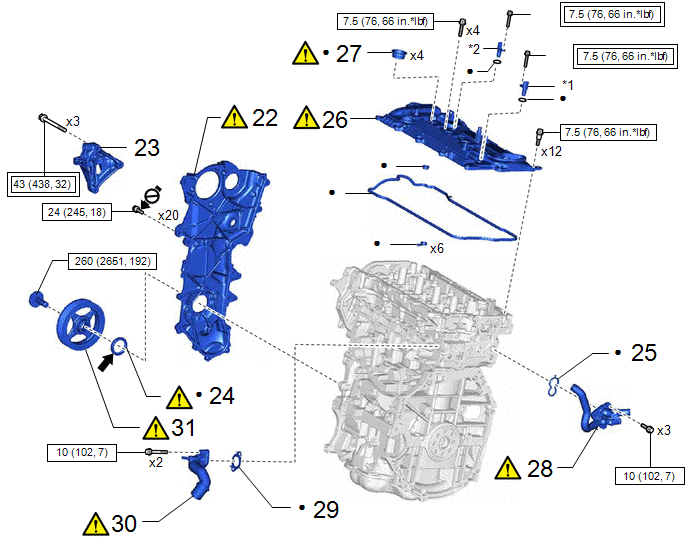

22 | NO. 2 TIMING CHAIN COVER ASSEMBLY |

11320B |

|

- | - |

|

23 | ENGINE MOUNTING BRACKET RH |

12315A | - |

- | - |

|

24 | TIMING CHAIN COVER OIL SEAL |

11301C |

|

- | - |

|

25 | SPARK PLUG TUBE GASKET |

11193 | - |

- | - |

|

26 | CYLINDER HEAD COVER SUB-ASSEMBLY |

11201 |

|

- | - |

|

27 | WATER OUTLET PIPE GASKET |

16345 |

|

- | - |

|

28 | WATER BY-PASS OUTLET SUB-ASSEMBLY |

16305E |

|

- | - |

|

29 | WATER OUTLET GASKET |

16341 | - |

- | - |

|

30 | WATER OUTLET |

16331 |

|

- | - |

|

31 | CRANKSHAFT PULLEY ASSEMBLY |

13470 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

★ | Precoated part |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

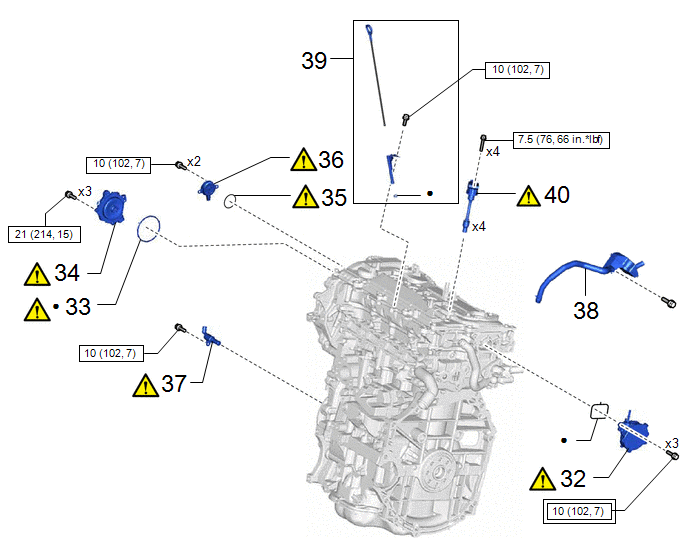

32 | VACUUM PUMP ASSEMBLY |

29300 |

|

- | - |

|

33 | CAM TIMING CONTROL MOTOR O-RING |

13090E |

|

- | - |

|

34 | CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY |

13090D |

|

- | - |

|

35 | CAM TIMING OIL CONTROL SOLENOID O-RING |

15370A |

|

- | - |

|

36 | CAM TIMING OIL CONTROL SOLENOID ASSEMBLY |

15370 |

|

- | - |

|

37 | OIL PRESSURE CONTROL VALVE ASSEMBLY |

15250 |

|

- | - |

|

38 | VACUUM SURGE TANK |

25719 | - |

- | - |

|

39 | ENGINE OIL LEVEL DIPSTICK GUIDE |

11452D | - |

- | - |

|

40 | IGNITION COIL ASSEMBLY |

19500 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

★ | Precoated part |

|

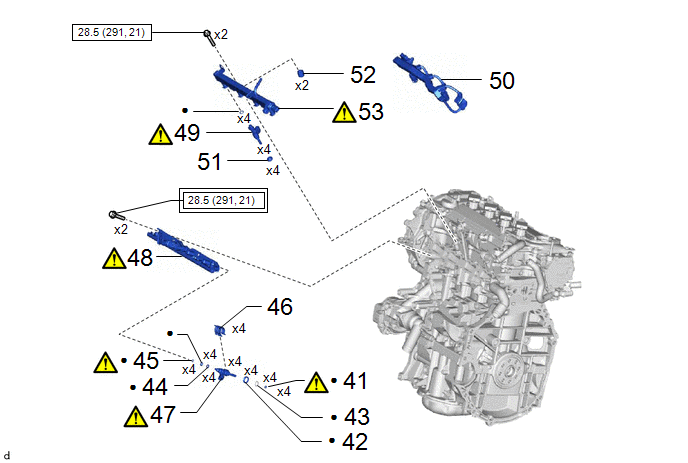

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

41 | FUEL INJECTOR SEAL |

23255A |

|

- | - |

|

42 | INJECTOR VIBRATION INSULATOR |

23291A | - |

- | - |

|

43 | C-RING |

- | - |

- | - |

|

44 | NO. 1 FUEL INJECTOR BACK-UP RING |

23256 | - |

- | - |

|

45 | NO. 3 FUEL INJECTOR BACK-UP RING |

23258 |

|

- | - |

|

46 | NOZZLE HOLDER CLAMP |

23695A | - |

- | - |

|

47 | DIRECT FUEL INJECTOR ASSEMBLY |

23250E |

|

- | - |

|

48 | FUEL DELIVERY PIPE |

23814B |

|

- | - |

|

49 | PORT FUEL INJECTOR ASSEMBLY |

23250F |

|

- | - |

|

50 | NO. 5 ENGINE WIRE |

82125N | - |

- | - |

|

51 | INJECTOR VIBRATION INSULATOR |

23291 | - |

- | - |

|

52 | FUEL DELIVERY SPACER |

23891 | - |

- | - |

|

53 | FUEL DELIVERY PIPE SUB-ASSEMBLY |

23807 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

|

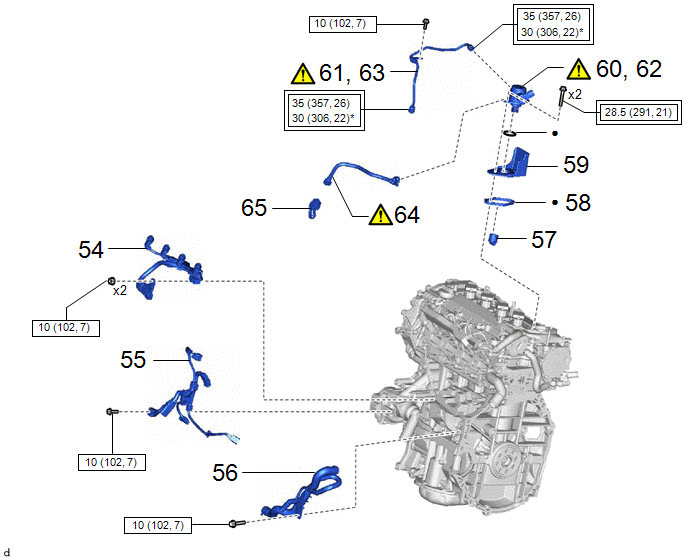

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

54 | NO. 6 ENGINE WIRE |

82126A | - |

- | - |

|

55 | SENSOR WIRE |

82219C | - |

- | - |

|

56 | NO. 1 WATER BY-PASS HOSE ASSEMBLY |

- | - |

- | - |

|

57 | FUEL PUMP LIFTER ASSEMBLY |

23470 | - |

- | - |

|

58 | FUEL PUMP SPACER GASKET |

23224D | - |

- | - |

|

59 | FUEL PUMP FLANGE |

23191 | - |

- | - |

|

60 | TEMPORARILY INSTALL FUEL(ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure) |

23100X |

|

- | - |

|

61 | TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY |

23801P |

|

- | - |

|

62 | INSTALL FUEL(ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure) |

23100X |

|

- | - |

|

63 | INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY |

23801P |

|

- | - |

|

64 | FUEL TUBE SUB-ASSEMBLY |

23910A |

|

- | - |

|

65 | FUEL PIPE CLAMP |

23841K | - |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

|

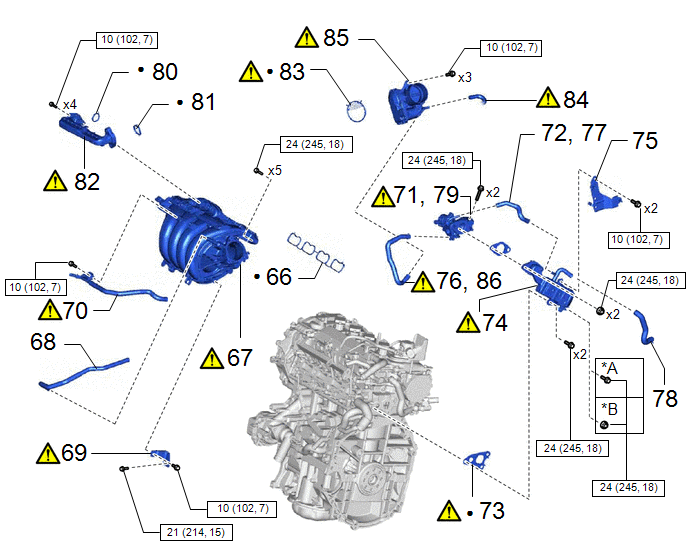

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

66 | NO. 1 INTAKE MANIFOLD TO HEAD GASKET |

17177 | - |

- | - |

|

67 | INTAKE MANIFOLD |

17111 |

|

- | - |

|

68 | NO. 1 FUEL VAPOR FEED HOSE |

23826 | - |

- | - |

|

69 | INTAKE MANIFOLD STAY |

17138B |

|

- | - |

|

70 | NO. 3 WATER BY-PASS PIPE |

16279 |

|

- | - |

|

71 | SET EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

72 | INSTALL NO. 4 WATER BY-PASS HOSE |

16281 | - |

- | - |

|

73 | NO. 1 EGR COOLER GASKET |

25685 |

|

- | - |

|

74 | EGR COOLER ASSEMBLY |

25680 |

|

- | - |

|

75 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

76 | INSTALL NO. 8 WATER BY-PASS HOSE |

16296 |

|

- | - |

|

77 | CONNECT NO. 4 WATER BY-PASS HOSE |

16281 | - |

- | - |

|

78 | NO. 3 WATER BY-PASS HOSE |

16267 | - |

- | - |

|

79 | INSTALL EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

80 | EGR INLET GASKET |

25628 | - |

- | - |

|

81 | EGR VALVE ADAPTER GASKET |

25629 | - |

- | - |

|

82 | NO. 1 EGR PIPE SUB-ASSEMBLY |

25601 |

|

- | - |

|

83 | THROTTLE BODY GASKET |

22271 |

|

- | - |

|

84 | NO. 5 WATER BY-PASS HOSE |

16282 |

|

- | - |

|

85 | THROTTLE BODY WITH MOTOR ASSEMBLY |

22030 |

|

- | - |

|

86 | CONNECT NO. 8 WATER BY-PASS HOSE |

16296 |

|

- | - |

|

*A | Type A |

*B | Type B |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

|

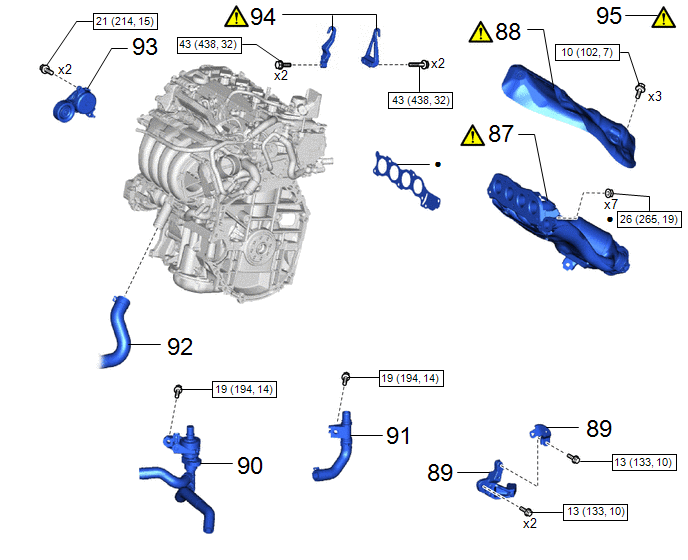

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

87 | EXHAUST MANIFOLD |

17141 |

|

- | - |

|

88 | NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

17167 |

|

- | - |

|

89 | WATER HOSE CLAMP BRACKET |

16575B | - |

- | - |

|

90 | FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY) |

16260 | - |

- | - |

|

91 | NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY |

16207 | - |

- | - |

|

92 | NO. 2 RADIATOR HOSE |

16572D | - |

- | - |

|

93 | V-RIBBED BELT TENSIONER ASSEMBLY |

16620D | - |

- | - |

|

94 | ENGINE HANGER |

- |

|

- | - |

|

95 | ENGINE ASSEMBLY FROM ENGINE STAND |

- |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

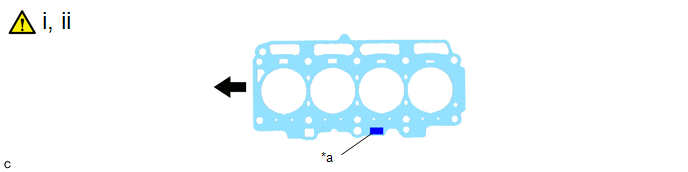

1. INSTALL CYLINDER HEAD GASKET

-

-

|

*a | Lot No. |

- | - |

.png) |

Front of Engine | - |

- |

(1) Clean the cylinder block sub-assembly and cylinder head sub-assembly with solvent.

(2) Place a new cylinder head gasket on the cylinder block sub-assembly as shown in the illustration.

NOTICE:

Make sure to install the cylinder head gasket in the correct direction.

2. INSTALL CYLINDER HEAD SUB-ASSEMBLY

Click here

.gif)

3. INSTALL VALVE LASH ADJUSTER ASSEMBLY

Click here .gif)

4. INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

Click here .gif)

5. INSTALL EXHAUST CAMSHAFT SUB-ASSEMBLY

Click here .gif)

6. INSTALL INTAKE CAMSHAFT SUB-ASSEMBLY

Click here .gif)

7. INSTALL CAMSHAFT BEARING CAP

Click here .gif)

8. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY

Click here .gif)

9. INSTALL FUEL PUMP LIFTER GUIDE

Click here .gif)

10. INSTALL TIMING CHAIN COVER ASSEMBLY

Click here .gif)

11. INSTALL CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

Click here .gif)

12. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

Click here .gif)

13. INSTALL NO. 1 CHAIN VIBRATION DAMPER

Click here .gif)

14. INSTALL CHAIN TENSIONER SLIPPER

Click here .gif)

15. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

Click here .gif)

16. INSTALL CRANKSHAFT TIMING GEAR OR SPROCKET

17. INSTALL CHAIN SUB-ASSEMBLY

Click here

.gif)

18. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

Click here .gif)

19. INSTALL OIL PUMP DRIVE CHAIN SUB-ASSEMBLY

Click here .gif)

20. INSTALL CHAIN TENSIONER PLATE

21. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

Click here

.gif)

22. INSTALL NO. 2 TIMING CHAIN COVER ASSEMBLY

Click here .gif)

23. INSTALL ENGINE MOUNTING BRACKET RH

24. INSTALL TIMING CHAIN COVER OIL SEAL

Click here

.gif)

25. INSTALL SPARK PLUG TUBE GASKET

Click here .gif)

26. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

Click here .gif)

27. INSTALL WATER OUTLET PIPE GASKET

28. INSTALL WATER BY-PASS OUTLET SUB-ASSEMBLY

Click here

.gif)

29. INSTALL WATER OUTLET GASKET

30. INSTALL WATER OUTLET

Click here .gif)

31. INSTALL CRANKSHAFT PULLEY ASSEMBLY

Click here .gif)

32. INSTALL VACUUM PUMP ASSEMBLY

Click here .gif)

33. INSTALL CAM TIMING CONTROL MOTOR O-RING

Click here .gif)

34. INSTALL CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

Click here .gif)

35. INSTALL CAM TIMING OIL CONTROL SOLENOID O-RING

36. INSTALL CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

Click here

.gif)

37. INSTALL OIL PRESSURE CONTROL VALVE ASSEMBLY

Click here .gif)

38. INSTALL VACUUM SURGE TANK

Click here .gif)

39. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

Click here .gif)

40. INSTALL IGNITION COIL ASSEMBLY

Click here .gif)

41. INSTALL FUEL INJECTOR SEAL

Click here .gif)

42. INSTALL INJECTOR VIBRATION INSULATOR

.png) |

Click here |

43. INSTALL C-RING

.png) |

Click here |

44. INSTALL NO. 1 FUEL INJECTOR BACK-UP RING

.png) |

|

45. INSTALL NO. 3 FUEL INJECTOR BACK-UP RING

.png) |

|

46. INSTALL NOZZLE HOLDER CLAMP

Click here .gif)

47. INSTALL DIRECT FUEL INJECTOR ASSEMBLY

Click here .gif)

48. INSTALL FUEL DELIVERY PIPE

Click here .gif)

49. INSTALL PORT FUEL INJECTOR ASSEMBLY

Click here .gif)

50. INSTALL NO. 5 ENGINE WIRE

Click here .gif)

51. INSTALL INJECTOR VIBRATION INSULATOR

Click here .gif)

52. INSTALL FUEL DELIVERY SPACER

Click here .gif)

53. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

Click here .gif)

54. INSTALL NO. 6 ENGINE WIRE

Click here .gif)

55. INSTALL SENSOR WIRE

Click here .gif)

56. INSTALL NO. 1 WATER BY-PASS HOSE ASSEMBLY

Click here .gif)

57. INSTALL FUEL PUMP LIFTER ASSEMBLY

58. INSTALL FUEL PUMP SPACER GASKET

59. INSTALL FUEL PUMP FLANGE

60. TEMPORARILY INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here .gif)

.gif)

61. TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

Click here

.gif)

.gif)

62. INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here .gif)

.gif)

63. INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

Click here

.gif)

64. CONNECT FUEL TUBE SUB-ASSEMBLY

Click here .gif)

65. INSTALL FUEL PIPE CLAMP

66. INSTALL NO. 1 INTAKE MANIFOLD TO HEAD GASKET

Click here

.gif)

67. INSTALL INTAKE MANIFOLD

Click here

.gif)

68. CONNECT NO. 1 FUEL VAPOR FEED HOSE

Click here .gif)

69. INSTALL INTAKE MANIFOLD STAY

Click here .gif)

70. INSTALL NO. 3 WATER BY-PASS PIPE

Click here .gif)

71. SET EGR VALVE ASSEMBLY

Click here .gif)

72. INSTALL NO. 4 WATER BY-PASS HOSE

73. INSTALL NO. 1 EGR COOLER GASKET

74. INSTALL EGR COOLER ASSEMBLY

Click here .gif)

75. INSTALL WIRE HARNESS CLAMP BRACKET

Click here .gif)

76. INSTALL NO. 8 WATER BY-PASS HOSE

77. CONNECT NO. 4 WATER BY-PASS HOSE

78. CONNECT NO. 3 WATER BY-PASS HOSE

79. INSTALL EGR VALVE ASSEMBLY

Click here

.gif)

80. INSTALL EGR INLET GASKET

81. INSTALL EGR VALVE ADAPTER GASKET

82. INSTALL NO. 1 EGR PIPE SUB-ASSEMBLY

Click here

.gif)

83. INSTALL THROTTLE BODY GASKET

Click here .gif)

84. INSTALL NO. 5 WATER BY-PASS HOSE

.png) |

Click here |

85. INSTALL THROTTLE BODY WITH MOTOR ASSEMBLY

Click here

.gif)

86. CONNECT NO. 8 WATER BY-PASS HOSE

.png) |

Click here |

87. INSTALL EXHAUST MANIFOLD

- for 2WD

Click here

.gif)

- for AWD

Click here

.gif)

88. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

Click here

.gif)

89. INSTALL WATER HOSE CLAMP BRACKET

90. INSTALL FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

Click here

.gif)

91. INSTALL NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

Click here .gif)

92. INSTALL NO. 2 RADIATOR HOSE

93. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

Click here

.gif)

94. INSTALL ENGINE HANGER

Click here

.gif)

95. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

Click here .gif)