Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

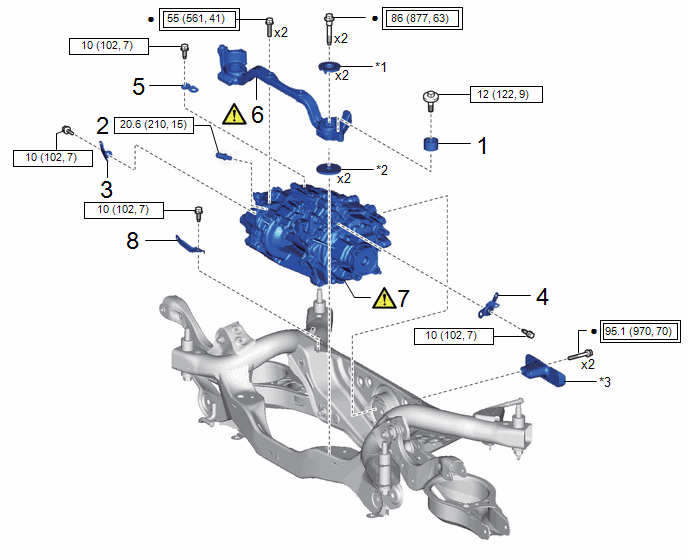

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

DIFFERENTIAL DYNAMIC DAMPER |

41196B |

- |

- |

- |

|

2 |

REAR TRACTION MOTOR BREATHER PLUG |

30900T |

- |

- |

- |

|

3 |

NO. 2 WIRING HARNESS CLAMP BRACKET |

82715S |

- |

- |

- |

|

4 |

NO. 2 MOTOR CABLE BRACKET |

G1143F |

- |

- |

- |

|

5 |

NO. 3 MOTOR CABLE BRACKET |

G1143G |

- |

- |

- |

|

6 |

FRONT DIFFERENTIAL SUPPORT ASSEMBLY |

52380F |

|

- |

- |

|

7 |

REAR TRACTION MOTOR WITH TRANSAXLE ASSEMBLY |

G1050 |

|

- |

- |

|

8 |

NO. 3 WIRING HARNESS CLAMP BRACKET |

82715T |

- |

- |

- |

|

*1 |

UPPER DIFFERENTIAL MOUNT STOPPER |

*2 |

LOWER DIFFERENTIAL MOUNT STOPPER |

|

*3 |

DIFFERENTIAL MASS DAMPER |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

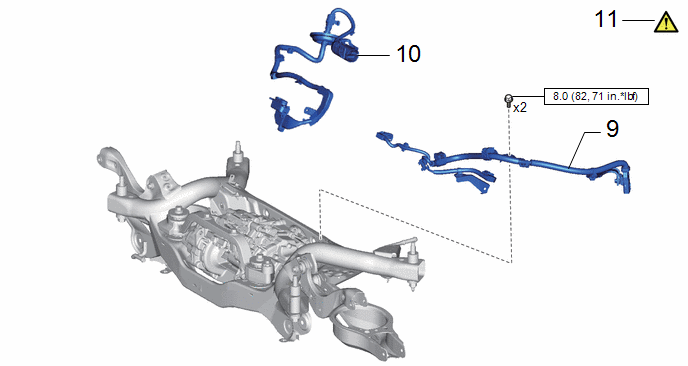

9 |

NO. 9 FLOOR WIRE |

8216C |

- |

- |

- |

|

10 |

REAR TRACTION MOTOR CABLE |

G1149 |

- |

- |

- |

|

11 |

PERFORM RESOLVER INITIALIZATION |

- |

|

- |

- |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

PROCEDURE

1. INSTALL DIFFERENTIAL DYNAMIC DAMPER

HINT:

Perform this procedure only when replacement of the differential dynamic damper is necessary.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

2. INSTALL REAR TRACTION MOTOR BREATHER PLUG

HINT:

Perform this procedure only when replacement of the rear traction motor breather plug is necessary.

Torque:

20.6 N·m {210 kgf·cm, 15 ft·lbf}

3. INSTALL NO. 2 WIRING HARNESS CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

4. INSTALL NO. 2 MOTOR CABLE BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

5. INSTALL NO. 3 MOTOR CABLE BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

6. TEMPORARILY TIGHTEN FRONT DIFFERENTIAL SUPPORT ASSEMBLY

(1) Temporarily install the front differential support assembly to the rear traction motor with transaxle assembly with 2 new bolts.

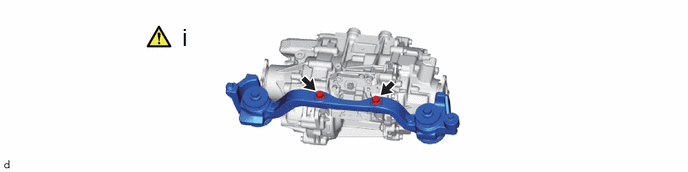

7. INSTALL REAR TRACTION MOTOR WITH TRANSAXLE ASSEMBLY

.png)

.png) |

Support Positions |

- |

- |

(1) Using an engine sling device and belts, support the rear traction motor with transaxle assembly in the position shown in the illustration.

NOTICE:

- Do not lift the rear traction motor with transaxle assembly any higher than is necessary.

- When lifting the rear traction motor with transaxle assembly, check the location of the center of gravity while lifting it.

|

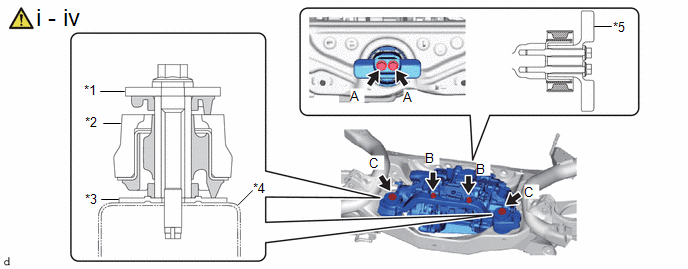

*1 |

UPPER DIFFERENTIAL MOUNT STOPPER |

*2 |

FRONT DIFFERENTIAL SUPPORT ASSEMBLY |

|

*3 |

LOWER DIFFERENTIAL MOUNT STOPPER |

*4 |

REAR SUSPENSION MEMBER SUB-ASSEMBLY |

|

*5 |

DIFFERENTIAL MASS DAMPER |

- |

- |

(1) Using 4 new bolts which are passed through the 2 upper differential mount stoppers, the 2 lower differential mount stoppers and the differential mass damper, temporarily install the rear traction motor with transaxle assembly to the rear suspension member sub-assembly.

(2) Fully tighten the 2 bolts (A).

Torque:

95.1 N·m {970 kgf·cm, 70 ft·lbf}

(3) Fully tighten the 2 bolts (B).

Torque:

55 N·m {561 kgf·cm, 41 ft·lbf}

(4) Fully tighten the 2 bolts (C).

Torque:

86 N·m {877 kgf·cm, 63 ft·lbf}

8. INSTALL NO. 3 WIRING HARNESS CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

9. INSTALL NO. 9 FLOOR WIRE

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

10. INSTALL REAR TRACTION MOTOR CABLE

Click here .gif)

11. PERFORM RESOLVER INITIALIZATION

.png) |

NOTICE: If the rear traction motor with transaxle assembly has been replaced, make sure to perform resolver learning. Click here |