Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

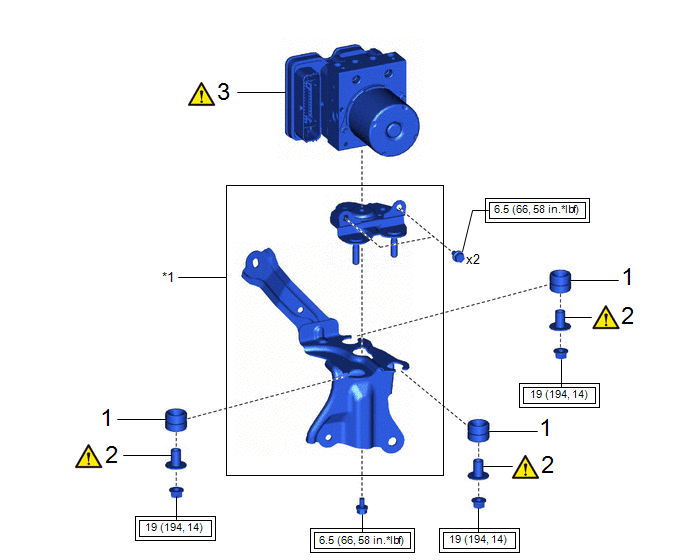

1 |

BRAKE ACTUATOR BRACKET CUSHION |

44547B |

- |

- |

- |

|

2 |

NO. 1 BRAKE ACTUATOR CASE COLLAR |

44521A |

|

- |

- |

|

3 |

BRAKE ACTUATOR ASSEMBLY |

44510 |

|

- |

- |

|

*1 |

BRAKE ACTUATOR BRACKET ASSEMBLY |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

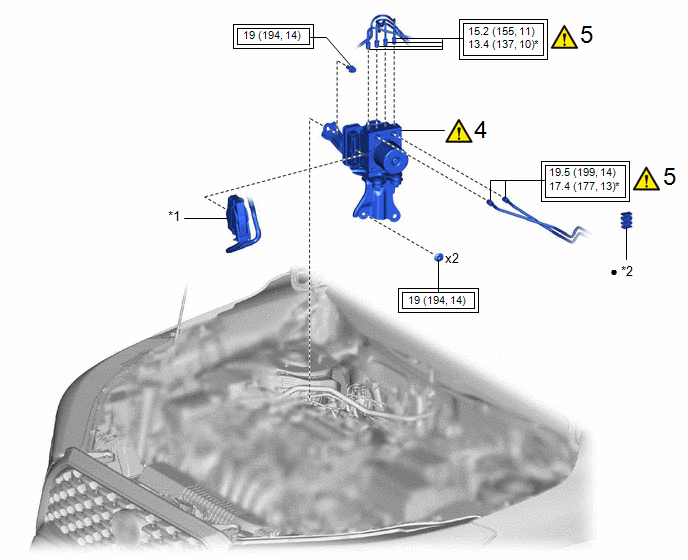

4 |

BRAKE ACTUATOR WITH BRACKET |

- |

|

- |

- |

|

5 |

BRAKE LINE |

- |

|

- |

- |

|

*1 |

CONNECTOR |

*2 |

No. 1 BRAKE TUBE CLAMP |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

* |

For use with a union nut wrench |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

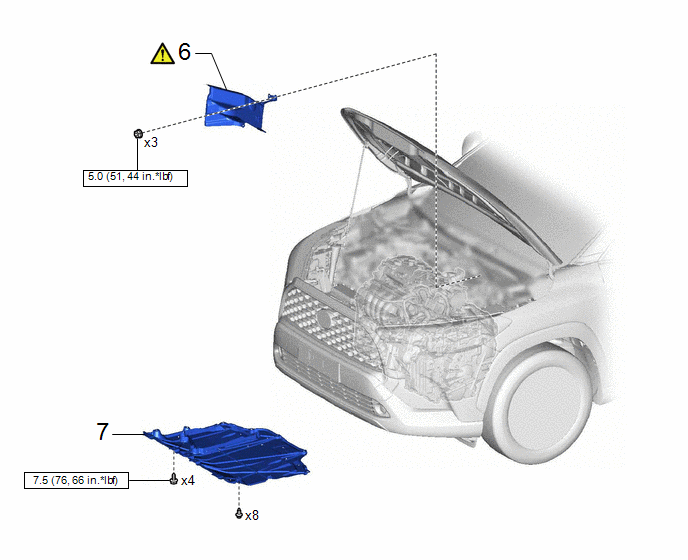

6 |

DASH PANEL HEAT INSULATOR |

55225C |

|

- |

- |

|

7 |

NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 |

- |

- |

- |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

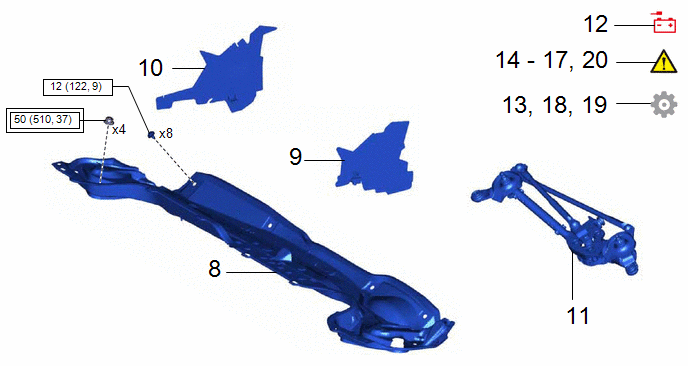

8 |

OUTER COWL TOP PANEL SUB-ASSEMBLY |

55701J |

- |

- |

- |

|

9 |

WATER GUARD PLATE |

55734D |

- |

- |

- |

|

10 |

NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL |

55737B |

- |

- |

- |

|

11 |

WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY |

- |

- |

- |

- |

|

12 |

CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL |

- |

- |

- |

- |

|

13 |

UPDATE ECU SECURITY KEY |

- |

- |

- |

|

|

14 |

BLEED BRAKE SYSTEM |

- |

|

- |

- |

|

15 |

ACCELERATION SENSOR ZERO POINT CALIBRATION AND STORE SYSTEM INFORMATION MEMORIZATION |

- |

|

- |

- |

|

16 |

PERFORM TEST MODE INSPECTION |

- |

|

- |

- |

|

17 |

INSPECT BRAKE ACTUATOR USING GTS |

- |

|

- |

- |

|

18 |

PERFORM INITIALIZATION |

- |

- |

- |

|

|

19 |

INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL |

- |

- |

- |

|

|

20 |

CHECK FOR AND CLEAR DTCS |

- |

- |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

|

N*m (kgf*cm, ft.*lbf): Specified torque |

CAUTION / NOTICE / HINT

NOTICE:

- After replacing the brake actuator assembly, make sure to perform update ECU security key.

- After performing the update ECU security key procedure, make sure to perform the initialization procedure for when the cable has been disconnected and reconnected to the negative (-) auxiliary battery terminal.

HINT:

The parking brake indicator light blinks (red) when the ignition switch is turned to ON after replacing the brake actuator assembly. Operate the electric parking brake switch assembly to turn off the parking brake indicator light.

PROCEDURE

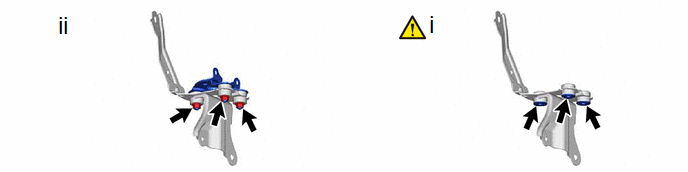

1. INSTALL BRAKE ACTUATOR BRACKET CUSHION

2. INSTALL NO. 1 BRAKE ACTUATOR CASE COLLAR

(1) Install the 3 No. 1 brake actuator case collars to the brake actuator bracket cushion.

NOTICE:

Make sure that the No. 1 brake actuator case collar is in full contact with the brake actuator bracket cushion.

(2) Install the brake actuator bracket assembly with the 3 nuts.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

3. INSTALL BRAKE ACTUATOR ASSEMBLY

(1) Temporarily install the brake actuator assembly with the 3 bolts.

(2) Fully tighten the 3 bolts in the order shown in the illustration.

Torque:

6.5 N·m {66 kgf·cm, 58 in·lbf}

NOTICE:

- Do not remove the hole plugs of a new brake actuator assembly before connecting the brake tubes because the brake actuator assembly is filled with brake fluid.

- Do not hold the brake actuator assembly by the connector.

- Do not drop the brake actuator assembly when carrying it.

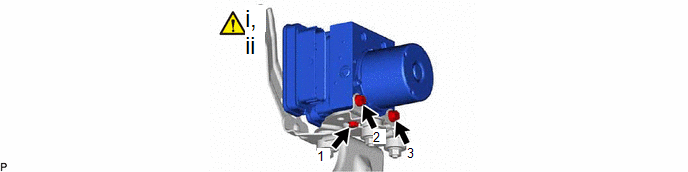

4. INSTALL BRAKE ACTUATOR WITH BRACKET

(1) Temporarily install the brake actuator with bracket to the vehicle body with the bolt and 2 nuts.

NOTICE:

- Do not kink or damage the brake lines.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

- Be careful not to allow any brake fluid to enter the connector.

- Do not hold the brake actuator assembly by the connector.

- Do not drop the brake actuator with bracket when carrying it.

- Install the brake actuator with bracket while avoiding the brake lines.

(2) Fully tighten the bolt and 2 nuts in the order shown in the illustration.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

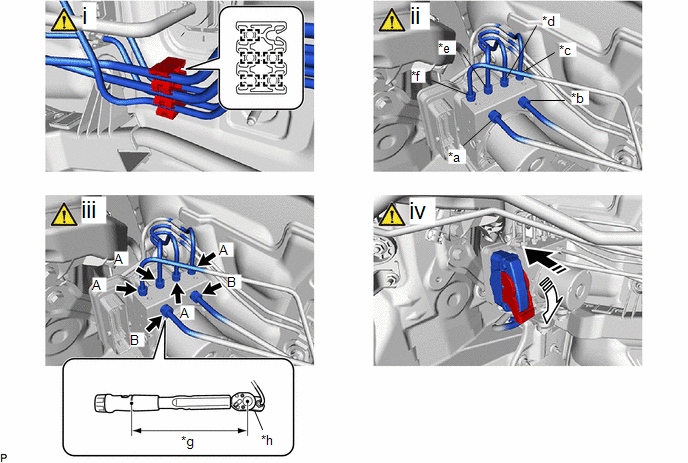

5. CONNECT BRAKE LINE

|

*a |

From 1st Chamber of Brake Master Cylinder Sub-assembly |

*b |

From 2nd Chamber of Brake Master Cylinder Sub-assembly |

|

*c |

To Front Wheel Cylinder Assembly RH |

*d |

To Rear Wheel Cylinder Assembly LH |

|

*e |

To Rear Wheel Cylinder Assembly RH |

*f |

To Front Wheel Cylinder Assembly LH |

|

*g |

Torque Wrench Fulcrum Length |

*h |

Union Nut Wrench |

.png) |

Connect the connector |

.png) |

Lock the lock lever |

(1) Engage the 5 clamps to install a new No. 1 brake tube clamp to the brake lines.

NOTICE:

Do not kink or damage the brake lines.

(2) Temporarily tighten each brake line to the correct position on the brake actuator assembly as shown in the illustration.

NOTICE:

- Do not kink or damage the brake line.

- Do not allow any foreign matter such as dirt or dust to enter the brake line from the connecting parts.

(3) Using a union nut wrench, connect the 6 brake lines to the brake actuator assembly.

Torque:

Specified tightening torque (A) :

15.2 N·m {155 kgf·cm, 11 ft·lbf}

Specified tightening torque (B) :

19.5 N·m {199 kgf·cm, 14 ft·lbf}

NOTICE:

- Do not kink or damage the brake lines.

- Do not allow the brake lines to twist or interfere with other parts or the vehicle body during tightening.

- Do not allow any foreign matter such as dirt or dust to enter the brake lines from the connecting parts.

HINT:

- Calculate the torque wrench reading when changing the fulcrum length

of the torque wrench.

Click here

.gif)

- When using a union nut wrench (fulcrum length of 22 mm (0.866 in.))

+ torque wrench (fulcrum length of 162 mm (6.38 in.)):

(A): 13.4 N*m (137 kgf*cm, 10 ft.*lbf)

- When using a union nut wrench (fulcrum length of 20 mm (0.787 in.))

+ torque wrench (fulcrum length of 162 mm (6.38 in.)):

(B): 17.4 N*m (177 kgf*cm, 13 ft.*lbf)

(4) Connect the connector to the brake actuator assembly and lock the lock lever.

NOTICE:

- Make sure that the connector is locked securely.

- Make sure that the actuator connector can be connected smoothly.

- Do not allow water, oil or dirt to enter the connector.

6. INSTALL DASH PANEL HEAT INSULATOR

(1) Temporarily install the dash panel heat insulator to the vehicle body with the 2 nuts (A).

(2) Install the nut (B).

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

(3) Tighten the 2 nuts (A).

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

7. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

8. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

Click here .gif)

9. INSTALL WATER GUARD PLATE

10. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

11. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

Click here .gif)

12. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

Click here .gif)

13. UPDATE ECU SECURITY KEY

Click here .gif)

14. BLEED BRAKE SYSTEM

Click here .gif)

15. ACCELERATION SENSOR ZERO POINT CALIBRATION AND STORE SYSTEM INFORMATION MEMORIZATION

Click here .gif)

16. PERFORM TEST MODE INSPECTION

Click here .gif)

17. INSPECT BRAKE ACTUATOR USING GTS

Click here .gif)

18. PERFORM INITIALIZATION

Click here .gif)

HINT:

The parking brake indicator light blinks (red) when the ignition switch is turned to ON after replacing the brake actuator assembly. Operate the electric parking brake switch assembly to turn off the parking brake indicator light.

19. INITIALIZATION AFTER RECONNECTING AUXILIARY BATTERY TERMINAL

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here .gif)

20. CHECK FOR AND CLEAR DTCS

Click here .gif)