Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

|

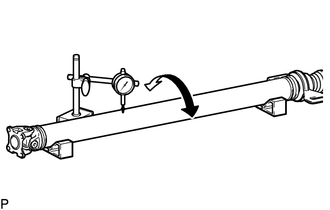

(a) Using a dial indicator, measure the runout of the intermediate shaft

assembly.

Maximum Runout:

0.6 mm (0.0236 in.)

NOTICE:

The dial indicator must be set at a right angle to the center of the

intermediate shaft assembly.

|

|

(b) If the runout is more than the maximum, replace the propeller shaft with

center bearing assembly.

|

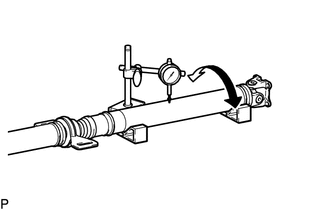

(c) Using a dial indicator, measure the runout of the propeller shaft

assembly.

Maximum Runout:

0.4 mm (0.0157 in.)

If the runout is more than the maximum, replace the propeller shaft with

center bearing assembly.

NOTICE:

The dial indicator must be set at a right angle to the center of the

propeller shaft assembly.

|

|

(d) Check that there is no excessive play and the joint part moves smoothly when

moving the joint part up and down, left and right, and in the direction of the axis.

READ NEXT:

REASSEMBLY

CAUTION / NOTICE / HINT

COMPONENTS (REASSEMBLY)

Procedure

Part Name Code

1

UNIVERSAL BOOT KIT

-

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

Procedure

Part Name Code

1

TEMPORARILY INSTALL PROPELLER

Problem Symptoms Table

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple

suspected areas are listed, the potential causes of the symp

SEE MORE:

DTC SUMMARY MALFUNCTION DESCRIPTION These DTCs indicate that the current sensor value is abnormal. The cause of this malfunction may be one of the following: Inverter internal malfunction

Inverter with converter assembly internal circuit malfunction

Inverter low-voltage circuit malfunctio

Performing the following

operations when carrying

the electronic key on your

person starts the engine or

changes engine switch

modes.

Starting the engine

1. Check that the parking brake

is set.

2. Check that the shift lever is in

P.

3. Firmly depress the brake

pedal.

and a message will be displa