Toyota Corolla Cross: Generator Inverter Actuator Stuck Closed (P0A7A73)

DTC SUMMARY

MALFUNCTION DESCRIPTION

This DTC is stored when a short is detected in the inverter with converter assembly (generator inverter) or the hybrid vehicle transaxle assembly (generator (MG1)). The cause of this malfunction may be one of the following:

Internal inverter malfunction- Generator inverter internal circuit malfunction

- Open or short circuit

- Damage from iron particles or other foreign objects

DESCRIPTION

For a description of the inverter.

Click here .gif)

|

DTC No. | Detection Item |

DTC Detection Condition |

Trouble Area | MIL |

Warning Indicate | Note |

|---|---|---|---|---|---|---|

|

P0A7A73 | Generator Inverter Actuator Stuck Closed |

Current flow to any phase of the generator (MG1) exceeds the threshold after the generator inverter is shut down due to a DTC indicating a generator inverter malfunction (overheating, overcurrent or circuit malfunction) being stored. (1 trip detection logic) |

| Comes on |

Master Warning: Comes on |

SAE Code: P0A7A |

MONITOR DESCRIPTION

The motor generator control ECU monitors the generator inverter electric current. If the current exceeds the threshold for a specified period of time, the motor generator control ECU will illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs | P0A7A (INF P0A7A73): GFIV detection (Short circuit malfunction) |

|

Required sensors/components | Generator inverter |

|

Frequency of operation | Continuous |

|

Duration | TMC's intellectual property |

|

MIL operation | 1 driving cycle |

|

Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property | - |

COMPONENT OPERATING RANGE

|

Motor generator control ECU | DTC P0A7A (INF P0A7A73) is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

.gif)

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

.gif)

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and wait for 5 seconds or more. [*1]

- Turn the ignition switch to ON (READY) and wait for 5 seconds or more. [*2]

HINT:

Check that there are no abnormalities (abnormal sounds, coolant leaks, etc.).

- Drive the vehicle for approximately 10 minutes mainly using the engine. [*3]

NOTICE:

As the state of charge of the HV battery may be low after driving in fail-safe mode, it will automatically be charged for 5 to 10 minutes with ignition switch ON (READY) after repairs have been performed.

HINT:

[*1] to [*3]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Motor Generator / Utility / All Readiness.

- Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for the Generator High-voltage Circuit.

Click here .gif)

CAUTION / NOTICE / HINT

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here .gif)

NOTICE:

- After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

.gif)

- When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

.gif)

- DTC P0A7A73 is stored after DTC P0A7A9E and/or P1C5F19 is stored. After troubleshooting and repairing the malfunction which caused DTC P0A7A73 to be stored, be sure to troubleshoot the other DTCs.

- Depending on the conditions in which the vehicle is being operated when a short circuit occurs in the inverter with converter assembly, the hybrid vehicle transaxle assembly may be affected. As this DTC is stored if a short circuit occurs in the inverter with converter assembly, it is necessary to perform a road test to check the hybrid vehicle transaxle assembly. If problems are found, replace the malfunctioning parts.

- After completing the repair, including the repair of previously output DTCs, drive the vehicle at a speed of approximately 40 km/h (25 mph) for 1 minute and check that DTC P0A92000 is not output. If DTC P0A92000 is output, replace the hybrid vehicle transaxle assembly.

HINT:

- P0A7A73 may be output as a result of the malfunctions indicated by the DTCs in table below.

- The chart above is listed in inspection order of priority.

- Check DTCs that are output at the same time by following the listed order. (The main cause of the malfunction can be determined without performing unnecessary inspections.)

|

Malfunction Content |

Relevant DTC | |

|---|---|---|

|

Insulation malfunction |

P1C7C49 | Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure |

|

P1C7D49 | Hybrid/EV Battery Voltage System Isolation (Hybrid/EV Battery Area) Internal Electronic Failure | |

|

P1C7E49 | Hybrid/EV Battery Voltage System Isolation (Transaxle Area) Internal Electronic Failure | |

|

P1C7F49 | Hybrid/EV Battery Voltage System Isolation (Direct Current Area) Internal Electronic Failure | |

|

P1C8049 | Hybrid/EV Battery Voltage System Isolation (Rear Motor Area) Internal Electronic Failure | |

PROCEDURE

|

1. | CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (GENERATOR (MG1)) |

Click here .gif)

| NG | .gif) | GO TO STEP 3 |

|

|

2. | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

Click here .gif)

| NEXT | .gif) | GO TO STEP 12 |

|

3. | CHECK MOTOR CABLE (FOR MG1) |

Click here .gif)

| NG | .gif) | GO TO STEP 6 |

|

|

4. | REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY |

Click here .gif)

|

|

5. | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

Click here .gif)

| NEXT | .gif) | GO TO STEP 12 |

|

6. | CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (GENERATOR (MG1)) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Disconnect the motor cable from the hybrid vehicle transaxle assembly.

| (c) Check the generator (MG1) for an interphase short using a milliohmmeter. (1) Using a milliohmmeter, measure the resistance according to the value(s) in the table below. HINT: If the generator (MG1) temperature is high, the resistance will vary greatly from the specification. Therefore, measure the resistance at least 8 hours after the vehicle has been stopped. Standard Resistance:

HINT: To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F).

The calculation is based on the following:

|

|

(d) Check the difference in measured resistance values according to the table below.

Standard:

|

Inspection Item | Specified Condition |

|---|---|

|

[*1] - [*2] | -1.1 to 0.9 mΩ |

|

[*2] - [*3] | -1.2 to 0.8 mΩ |

|

[*3] - [*1] | -0.7 to 1.3 mΩ |

(e) Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

NOTICE:

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

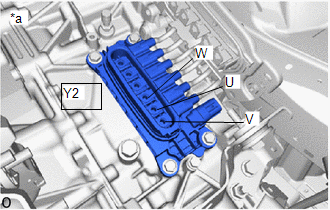

Y2-4 (W) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-5 (U) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-6 (V) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

(f) Connect the motor cable.

| NG | .gif) | GO TO STEP 9 |

|

|

7. | REPLACE MOTOR CABLE |

Click here .gif)

|

|

8. | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

Click here .gif)

| NEXT | .gif) | GO TO STEP 12 |

|

9. | REPLACE MOTOR CABLE |

Click here .gif)

|

|

10. | REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY |

Click here .gif)

|

|

11. | REPLACE INVERTER WITH CONVERTER ASSEMBLY |

Click here .gif)

|

|

12. | CHECK DTC OUTPUT (MOTOR GENERATOR) |

(a) Check the other DTCs that were output together with DTC P0A7A73.

Powertrain > Motor Generator > Trouble Codes|

Relevant DTC | |

|---|---|

|

P0A7A9E | Generator Inverter Stuck On |

|

P1C5F19 | Generator Inverter Circuit Current Above Threshold |

NOTICE:

DTC P0A7A73 is stored after DTC P0A7A9E and/or P1C5F19 is stored. After troubleshooting and repairing the malfunction which caused DTC P0A7A73 to be stored, be sure to troubleshoot the other DTCs.

| NEXT | .gif) | GO TO DTC CHART (MOTOR GENERATOR CONTROL SYSTEM) |

.gif)