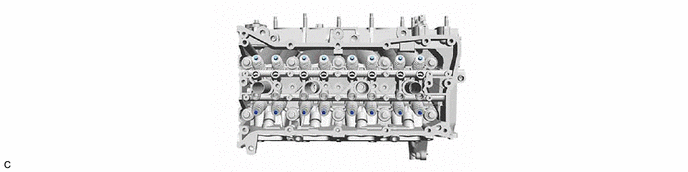

Toyota Corolla Cross: Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

COMPONENTS (DISASSEMBLY)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

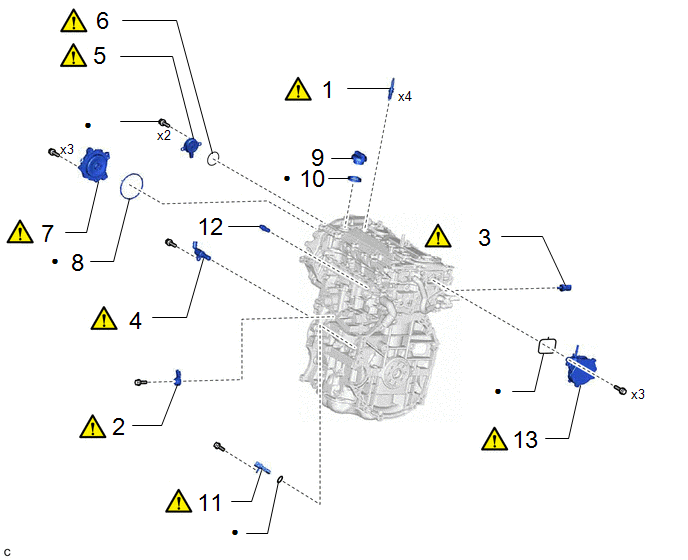

1 | SPARK PLUG |

19100P |

|

- | - |

|

2 | KNOCK CONTROL SENSOR |

89615 |

|

- | - |

|

3 | OIL PRESSURE AND TEMPERATURE SENSOR |

89448D |

|

- | - |

|

4 | OIL PRESSURE CONTROL VALVE ASSEMBLY |

15250 |

|

- | - |

|

5 | CAM TIMING OIL CONTROL SOLENOID ASSEMBLY |

15370 |

|

- | - |

|

6 | CAM TIMING OIL CONTROL SOLENOID O-RING |

13090E |

|

- | - |

|

7 | CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY |

13090D |

|

- | - |

|

8 | CAM TIMING CONTROL MOTOR O-RING |

13090E | - |

- | - |

|

9 | OIL FILLER CAP ASSEMBLY |

12180E | - |

- | - |

|

10 | OIL FILLER CAP GASKET |

12108A | - |

- | - |

|

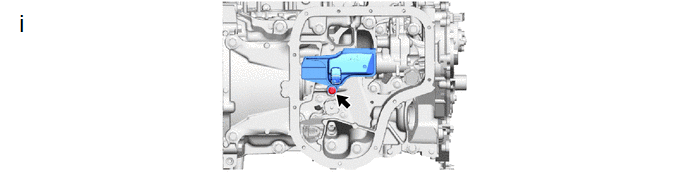

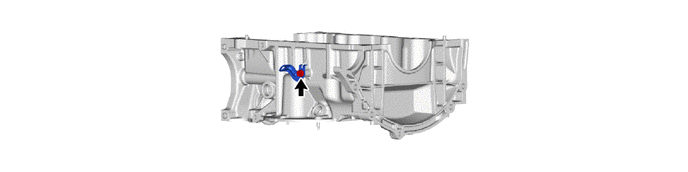

11 | CRANKSHAFT POSITION SENSOR |

11401G |

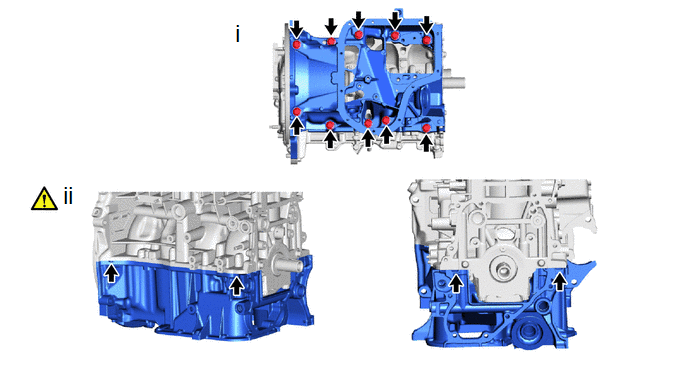

|

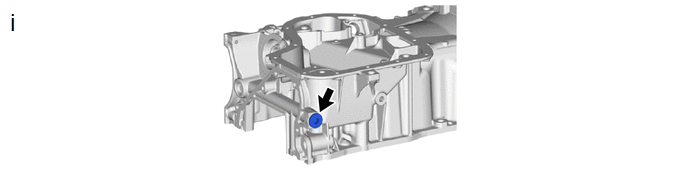

- | - |

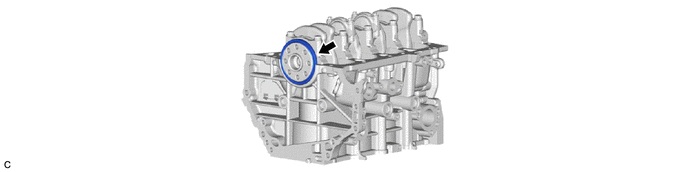

|

12 | PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY) |

12204C | - |

- | - |

|

13 | VACUUM PUMP ASSEMBLY |

29300 |

|

- | - |

|

● | Non-reusable part |

★ | Precoated part |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

14 | CRANKSHAFT PULLEY ASSEMBLY |

13470 |

|

- | - |

|

15 | WATER OUTLET |

16331 |

|

- | - |

|

16 | WATER OUTLET GASKET |

16341 | - |

- | - |

|

17 | WATER BY-PASS OUTLET SUB-ASSEMBLY |

16305E |

|

- | - |

|

18 | WATER OUTLET PIPE GASKET |

16345 | - |

- | - |

|

19 | CAMSHAFT POSITION SENSOR (for Intake Side) |

11102A |

|

- | - |

|

20 | CAMSHAFT POSITION SENSOR (for Exhaust Side) |

11102A |

|

- | - |

|

21 | CYLINDER HEAD COVER SUB-ASSEMBLY |

11201 |

|

- | - |

|

22 | SPARK PLUG TUBE GASKET |

11193 |

|

- | - |

|

23 | ENGINE MOUNTING BRACKET RH |

12315A | - |

- | - |

|

24 | STRAIGHT SCREW PLUG |

- |

|

- | - |

|

25 | NO. 2 TIMING CHAIN COVER ASSEMBLY |

11320B |

|

- | - |

|

26 | TIMING CHAIN COVER OIL SEAL |

11301C |

|

- | - |

|

● | Non-reusable part |

★ | Precoated part |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

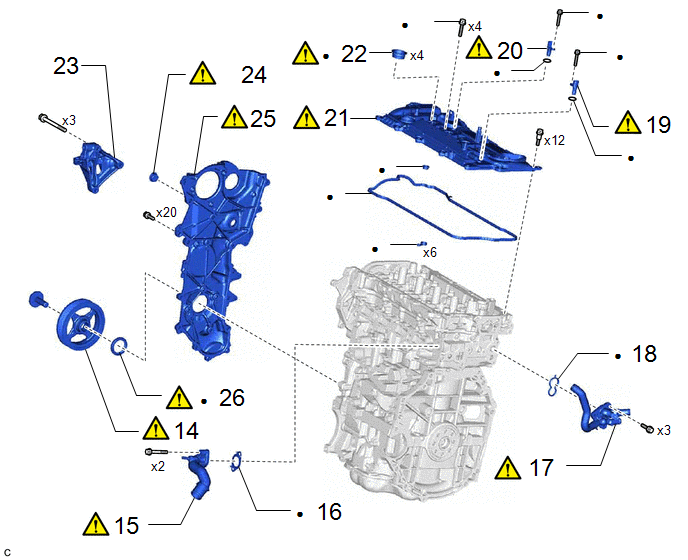

27 | NO. 1 CYLINDER TO TDC (COMPRESSION) |

- |

|

- | - |

|

28 | CHAIN TENSIONER PLATE |

- | - |

- | - |

|

29 | OIL PUMP DRIVE CHAIN SUB-ASSEMBLY |

13507A |

|

- | - |

|

30 | CAMSHAFT TIMING GEAR ASSEMBLY |

13050 |

|

- | - |

|

31 | CHAIN SUB-ASSEMBLY |

13506 | - |

- | - |

|

32 | CRANKSHAFT TIMING SPROCKET |

13521 | - |

- | - |

|

33 | NO. 1 CHAIN TENSIONER ASSEMBLY |

13540 |

|

- | - |

|

34 | CHAIN TENSIONER SLIPPER |

13559 | - |

- | - |

|

35 | NO. 1 CHAIN VIBRATION DAMPER |

13561 | - |

- | - |

|

36 | CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

13070A |

|

- | - |

|

37 | TIMING CHAIN COVER ASSEMBLY |

11310 |

|

- | - |

|

38 | OIL NOZZLE VALVE SUB-ASSEMBLY |

15703A | - |

- | - |

|

39 | CRANKSHAFT TIMING GEAR KEY |

13471A |

|

- | - |

|

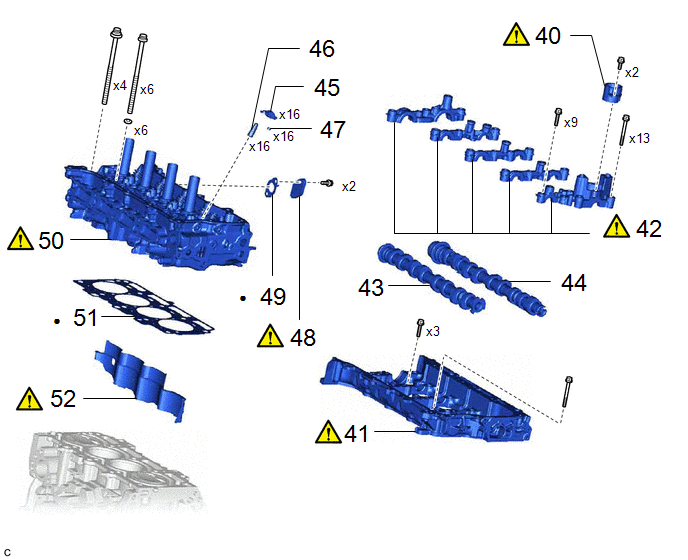

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

40 | FUEL PUMP LIFTER GUIDE |

23477 |

|

- | - |

|

41 | CAMSHAFT HOUSING SUB-ASSEMBLY |

11103 |

|

- | - |

|

42 | CAMSHAFT BEARING CAP |

- |

|

- | - |

|

43 | INTAKE CAMSHAFT SUB-ASSEMBLY |

13501A | - |

- | - |

|

44 | EXHAUST CAMSHAFT SUB-ASSEMBLY |

13502B | - |

- | - |

|

45 | NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

13801 | - |

- | - |

|

46 | VALVE LASH ADJUSTER ASSEMBLY |

13750 | - |

- | - |

|

47 | VALVE STEM CAP |

13716 | - |

- | - |

|

48 | WATER SEAL PLATE |

11492B |

|

- | - |

|

49 | WATER SEAL PLATE GASKET |

11493A | - |

- | - |

|

50 | CYLINDER HEAD SUB-ASSEMBLY |

11101 |

|

- | - |

|

51 | CYLINDER HEAD GASKET |

11115 | - |

- | - |

|

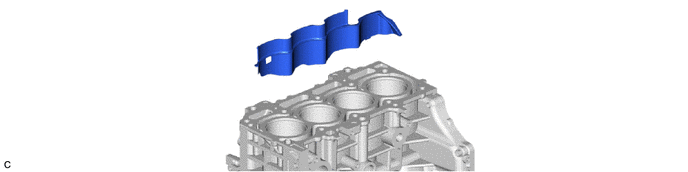

52 | CYLINDER BLOCK WATER JACKET SPACER |

11445 |

|

- | - |

|

● | Non-reusable part |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

53 | OIL FILTER SUB-ASSEMBLY |

15601 | - |

- | - |

|

54 | OIL FILTER UNION |

15600A |

|

- | - |

|

55 | OIL PAN DRAIN PLUG |

12101A | - |

- | - |

|

56 | OIL PAN SUB-ASSEMBLY |

12101 |

|

- | - |

|

57 | OIL STRAINER SUB-ASSEMBLY |

15104 |

|

- | - |

|

58 | ENGINE OIL LEVEL SENSOR |

89491 |

|

- | - |

|

59 | OIL PUMP ASSEMBLY |

15100 |

|

- | - |

|

60 | STIFFENING CRANKCASE ASSEMBLY |

11420 |

|

- | |

|

61 | STRAIGHT SCREW PLUG |

- |

|

- | - |

|

62 | REAR ENGINE OIL SEAL |

11401L |

|

- | - |

|

63 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

● | Non-reusable part |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

64 | STUD BOLT |

- |

|

- | - |

|

65 | RING PIN |

- |

|

- | - |

|

66 | STRAIGHT PIN |

- |

|

- | - |

|

● | Non-reusable part |

- | - |

CAUTION / NOTICE / HINT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during electric power steering column sub-assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Inspection After Repair |

|

|

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

1. REMOVE SPARK PLUG

.png) |

Click here |

2. REMOVE KNOCK CONTROL SENSOR

.png) |

Click here |

3. REMOVE OIL PRESSURE AND TEMPERATURE SENSOR

.png) |

Click here |

4. REMOVE OIL PRESSURE CONTROL VALVE ASSEMBLY

.png) |

Click here |

5. REMOVE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

.png) |

Click here |

6. REMOVE CAM TIMING OIL CONTROL SOLENOID O-RING

.png) |

Click here |

7. REMOVE CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

.png) |

Click here |

8. REMOVE CAM TIMING CONTROL MOTOR O-RING

Click here .gif)

.gif)

9. REMOVE OIL FILLER CAP ASSEMBLY

10. REMOVE OIL FILLER CAP GASKET

11. REMOVE CRANKSHAFT POSITION SENSOR

.png) |

Click here |

12. REMOVE PCV VALVE (VENTILATION VALVE SUB-ASSEMBLY)

Click here .gif)

13. REMOVE VACUUM PUMP ASSEMBLY

.png) |

Click here |

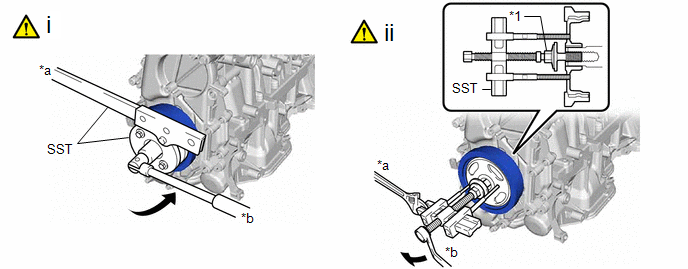

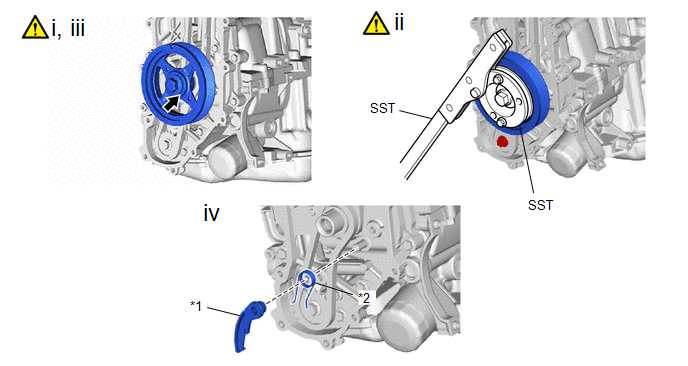

14. REMOVE CRANKSHAFT PULLEY ASSEMBLY

|

*1 | Crankshaft Pulley Bolt |

- | - |

|

*a | Hold |

*b | Turn |

.png) |

Turn | - |

- |

(1) Using SST, hold the crankshaft pulley assembly and loosen the crankshaft pulley bolt. Further loosen the crankshaft pulley bolt until 2 or 3 threads remain screwed into the crankshaft.

SST: 09213-54015

SST: 09330-00021

(2) Using SST and the crankshaft pulley bolt, remove the crankshaft pulley assembly and crankshaft pulley bolt.

SST: 09950-50013

09951-05010

09952-05010

09953-05020

09954-05070

09957-04010

HINT:

Apply lubricant to the threads and end of SST.

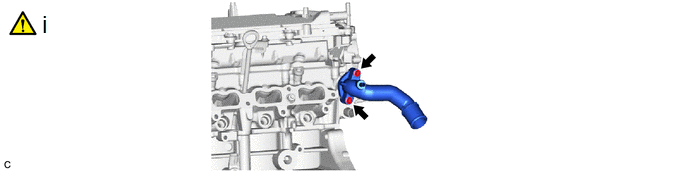

15. REMOVE WATER OUTLET

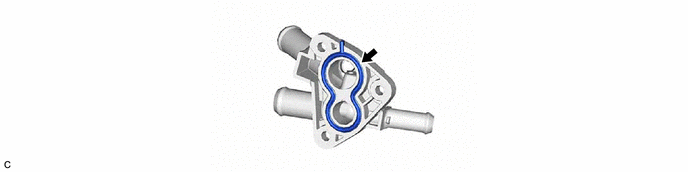

(1) Using an 8 mm socket wrench, remove the 2 bolts, water outlet and water outlet gasket from the cylinder head sub-assembly.

16. REMOVE WATER OUTLET GASKET

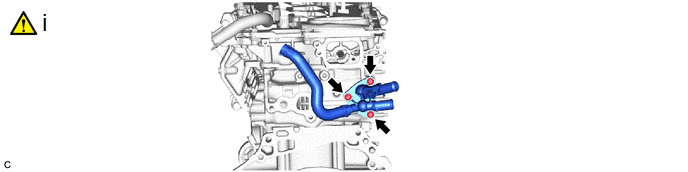

17. REMOVE WATER BY-PASS OUTLET SUB-ASSEMBLY

(1) Using an 8 mm socket wrench, remove the 3 bolts, water by-pass outlet sub-assembly and water pipe outlet gasket from the cylinder head sub-assembly.

18. REMOVE WATER OUTLET PIPE GASKET

19. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

.png) |

Click here |

20. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

.png) |

Click here |

21. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

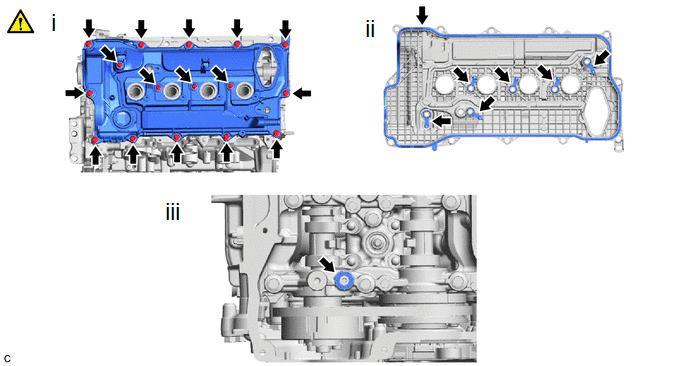

(1) Using an 8 mm socket wrench, remove the 16 bolts and cylinder head cover sub-assembly from the camshaft housing sub-assembly.

(2) Remove the 7 cylinder head cover gaskets from the cylinder head cover sub-assembly.

(3) Remove the camshaft bearing cap oil hole gasket from the No. 1 camshaft bearing cap.

22. REMOVE SPARK PLUG TUBE GASKET

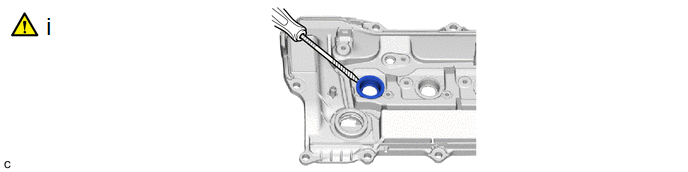

(1) Using a screwdriver, pry out the 4 spark plug tube gaskets from the cylinder head cover sub-assembly.

NOTICE:

Be careful not to damage the cylinder head cover sub-assembly.

HINT:

Tape the screwdriver tip before use.

23. REMOVE ENGINE MOUNTING BRACKET RH

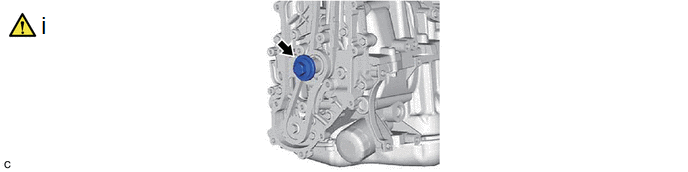

24. REMOVE STRAIGHT SCREW PLUG

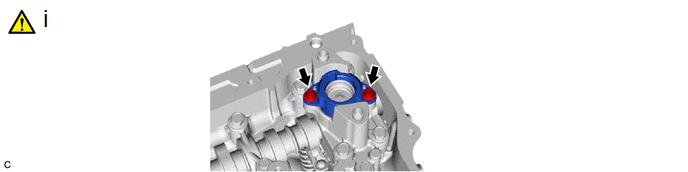

(1) Using a 10 mm hexagon wrench, remove the straight screw plug from the No. 2 timing chain cover assembly.

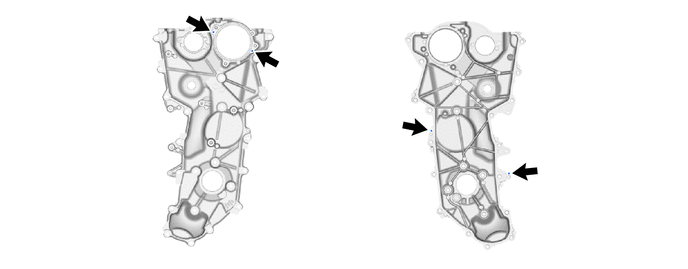

25. REMOVE NO. 2 TIMING CHAIN COVER ASSEMBLY

(1) Remove the 20 bolts.

(2) Remove the No. 2 timing chain cover assembly from the timing chain cover assembly by prying the No. 2 timing chain cover assembly with a screwdriver with its tip wrapped with protective tape.

NOTICE:

Be careful not to damage the contact surfaces of the No. 2 timing chain cover assembly and timing chain cover assembly.

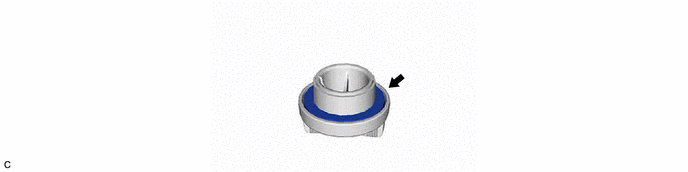

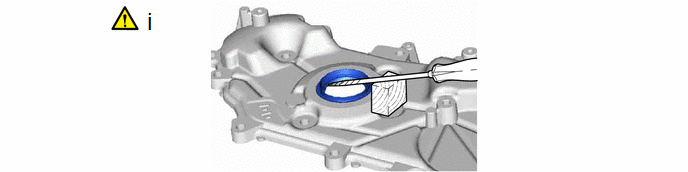

26. REMOVE TIMING CHAIN COVER OIL SEAL

(1) Using a screwdriver and wooden block, pry out the timing chain cover oil seal.

NOTICE:

Do not damage the surface of the timing chain cover oil seal press fit hole.

HINT:

Tape the screwdriver tip before use.

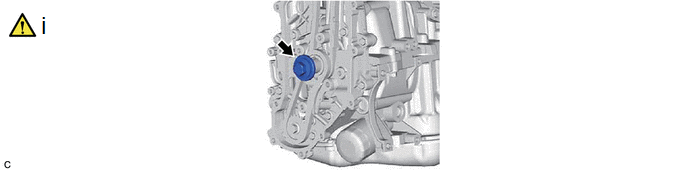

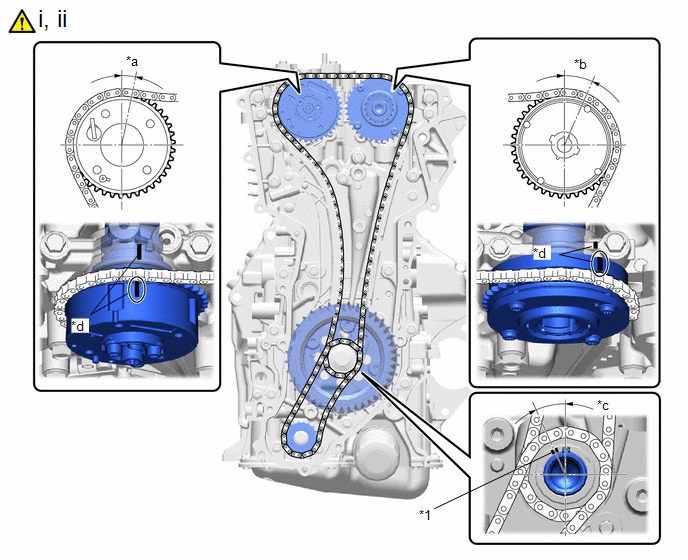

27. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

(1) Temporarily install the crankshaft pulley bolt.

|

*1 | Crankshaft Timing Gear Key |

- | - |

|

*a | Approximately 4.63° |

*b | Approximately 33.07° |

|

*c | Approximately 2.73° |

*d | Timing Mark |

(1) Rotate the crankshaft clockwise and align the crankshaft timing gear key as shown in the illustration.

(2) Check that the timing marks on the camshaft timing exhaust gear assembly and camshaft timing gear assembly are as shown in the illustration.

(1) Remove the crankshaft pulley bolt.

HINT:

As the exhaust camshaft sub-assembly may rotate counterclockwise strongly when the crankshaft pulley bolt is removed, use a wrench to hold the hexagonal portion of the exhaust camshaft sub-assembly.

28. REMOVE CHAIN TENSIONER PLATE

|

*1 | Chain Tensioner Plate |

*2 | Chain Damper Spring |

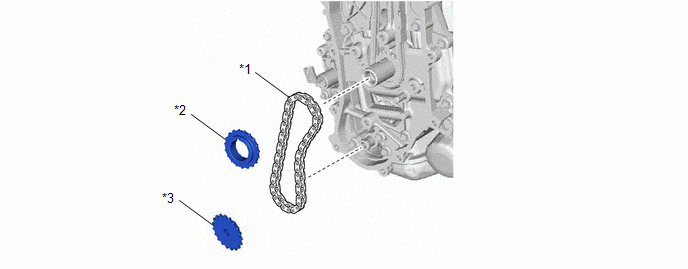

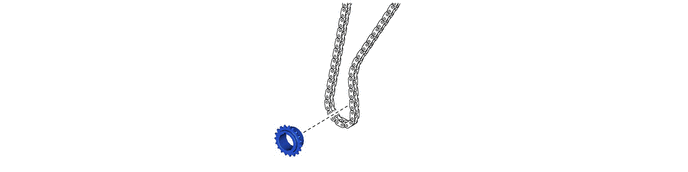

29. REMOVE OIL PUMP DRIVE CHAIN SUB-ASSEMBLY

|

*1 | Oil Pump Drive Chain Sub-assembly |

*2 | Oil Pump Drive Sprocket |

|

*3 | Oil Pump Drive Shaft Sprocket |

- | - |

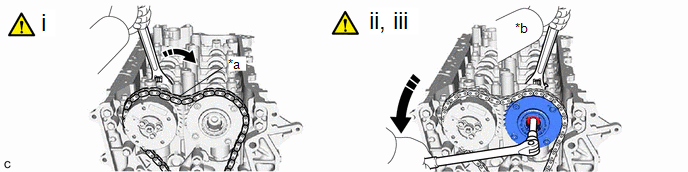

30. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

|

*a | Loosen |

*b | Hold |

.png) |

Turn | - |

- |

(1) Hold the hexagonal portion of the exhaust camshaft sub-assembly with a wrench and turn it clockwise to loosen the chain sub-assembly between the camshaft timing exhaust gear assembly and camshaft timing gear assembly.

(2) Using a wrench, hold the hexagonal portion of the intake camshaft sub-assembly.

NOTICE:

- Be careful not to damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube with the wrench.

- Do not disassemble the camshaft timing gear assembly.

(3) Using a 10 mm bi-hexagonal wrench, remove the bolt and camshaft timing gear assembly from the intake camshaft sub-assembly.

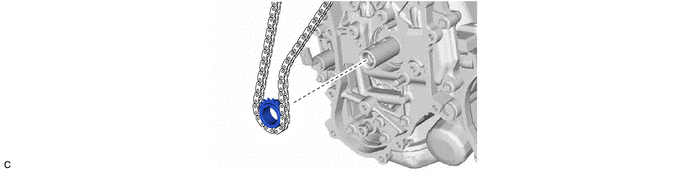

31. REMOVE CHAIN SUB-ASSEMBLY

32. REMOVE CRANKSHAFT TIMING SPROCKET

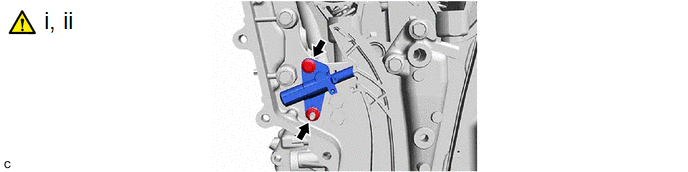

33. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

(1) Using an 8 mm socket wrench, remove the bolt.

(2) Remove the nut and No. 1 chain tensioner assembly from the timing chain cover assembly.

NOTICE:

Make sure that the plunger, check ball assembly and spring do not come out.

|

*a | Tape |

*b | Plunger |

|

*c | Check ball assembly |

*d | Spring |

|

*e | No. 1 chain tensioner assembly body |

- | - |

(1) Use tape to hold the plunger inside the No. 1 chain tensioner assembly.

NOTICE:

- Make sure that the plunger, check ball assembly and spring do not come out.

- If the No. 1 chain tensioner assembly comes apart, reinstall the parts as shown in the illustration.

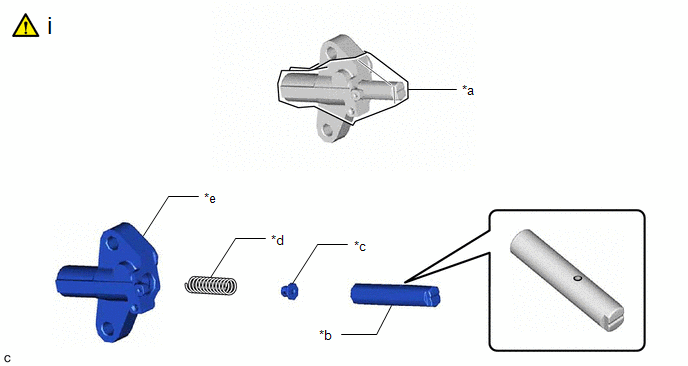

34. REMOVE CHAIN TENSIONER SLIPPER

35. REMOVE NO. 1 CHAIN VIBRATION DAMPER

36. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

|

*1 | Camshaft Timing Exhaust Gear Assembly |

*2 | Camshaft Timing Oil Control Valve Assembly (Exhaust Camshaft Timing Gear Bolt Assembly) |

(1) Using a wrench, hold the hexagonal portion of the exhaust camshaft sub-assembly.

NOTICE:

Be careful not to damage the camshaft housing sub-assembly, cylinder head sub-assembly or spark plug tube with the wrench.

(2) Using a 5 mm hexagon socket wrench, remove the 3 bolts.

(3) Remove the camshaft timing exhaust gear assembly and camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) from the exhaust camshaft sub-assembly.

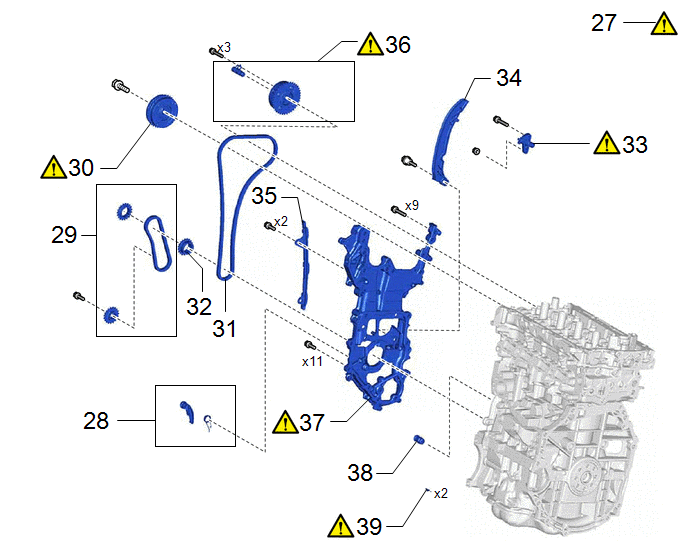

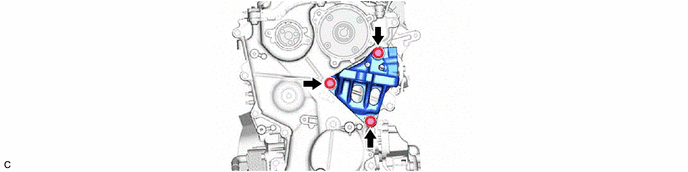

37. REMOVE TIMING CHAIN COVER ASSEMBLY

(1) Remove the 20 bolts and timing chain cover assembly from the camshaft housing sub-assembly, cylinder head sub-assembly, cylinder block sub-assembly, stiffening crankcase assembly and oil pump assembly.

(2) Remove the timing chain cover assembly by prying between the cylinder head sub-assembly, camshaft housing sub-assembly, cylinder block sub-assembly, oil pump assembly and stiffening crankcase assembly with a screwdriver with its tip wrapped with protective tape.

NOTICE:

Be careful not to damage the contact surfaces of the cylinder head sub-assembly, camshaft housing sub-assembly, cylinder block sub-assembly, stiffening crankcase assembly, oil pump assembly and timing chain cover assembly.

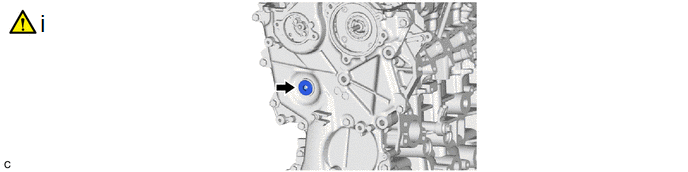

38. REMOVE OIL NOZZLE VALVE SUB-ASSEMBLY

39. REMOVE CRANKSHAFT TIMING GEAR KEY

(1) Using a screwdriver with its tip wrapped in protective tape, remove the 2 crankshaft timing gear keys from the crankshaft.

40. REMOVE FUEL PUMP LIFTER GUIDE

(1) Using an 8 mm socket wrench, remove the 2 bolts and fuel pump lifter guide from the No. 4 camshaft bearing cap.

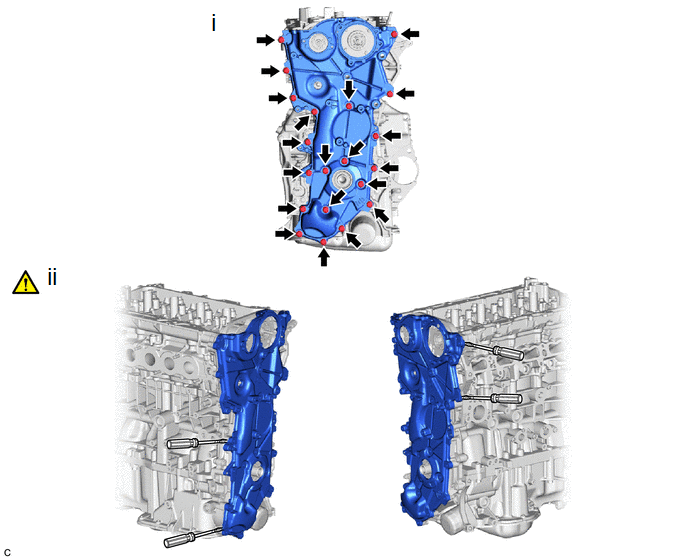

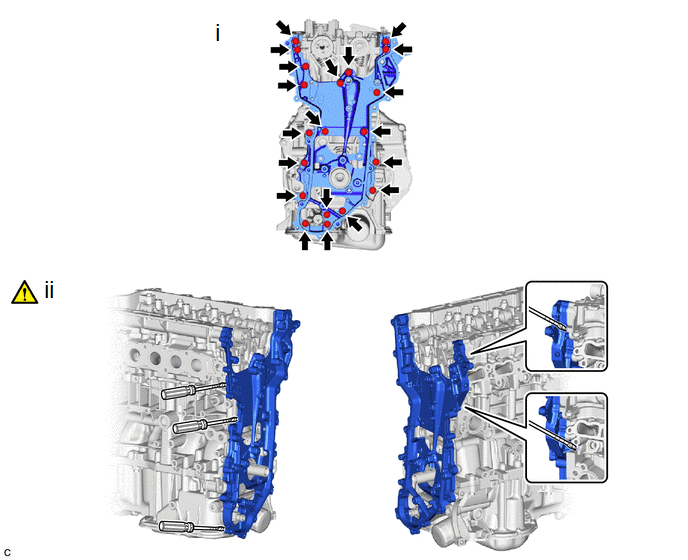

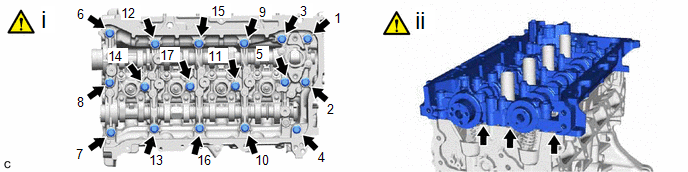

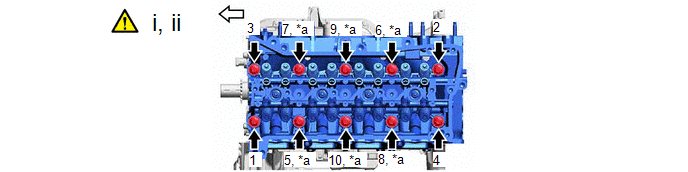

41. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

(1) Uniformly loosen and remove the 17 bolts in the order shown in the illustration.

(2) Using a screwdriver, remove the camshaft housing sub-assembly by prying between the cylinder head sub-assembly and camshaft housing sub-assembly at the places shown in the illustration.

NOTICE:

Be careful not to damage the contact surfaces of the cylinder head sub-assembly and camshaft housing sub-assembly.

HINT:

Tape the screwdriver tip before use.

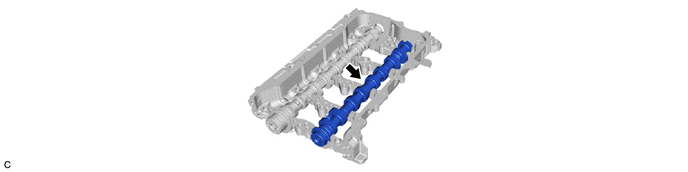

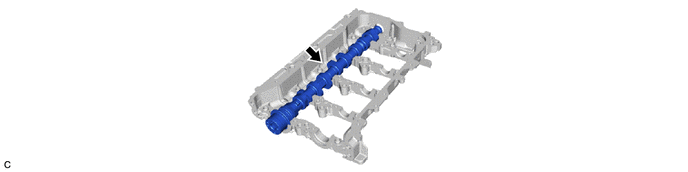

42. REMOVE CAMSHAFT BEARING CAP

|

*1 | No. 1 Camshaft Bearing Cap |

*2 | No. 2 Camshaft Bearing Cap |

|

*3 | No. 3 Camshaft Bearing Cap |

*4 | No. 4 Camshaft Bearing Cap |

(1) Uniformly loosen and remove the 9 bolts in the order shown in the illustration.

(2) Remove the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap, 2 No. 3 camshaft bearing caps and No. 4 camshaft bearing cap from the camshaft housing sub-assembly.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

43. REMOVE INTAKE CAMSHAFT SUB-ASSEMBLY

44. REMOVE EXHAUST CAMSHAFT SUB-ASSEMBLY

45. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

46. REMOVE VALVE LASH ADJUSTER ASSEMBLY

47. REMOVE VALVE STEM CAP

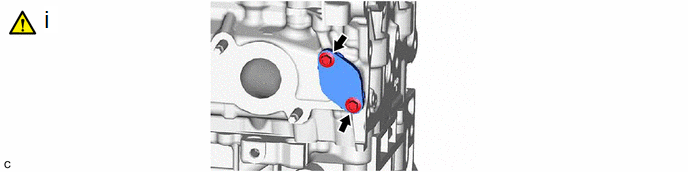

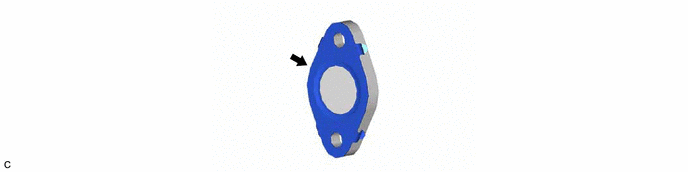

48. REMOVE WATER SEAL PLATE

(1) Using an 8 mm socket wrench, remove the 2 bolts, water seal plate and gasket from the cylinder head sub-assembly.

49. REMOVE WATER SEAL PLATE GASKET

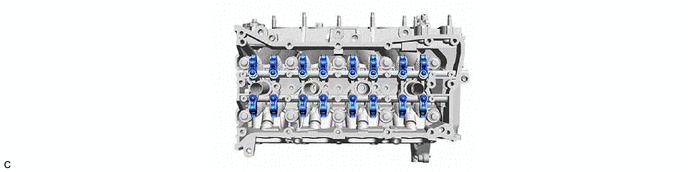

50. REMOVE CYLINDER HEAD SUB-ASSEMBLY

|

*a | Plate Washer |

- | - |

.png) |

Front of Engine | - |

- |

(1) Using a 12 mm socket wrench, uniformly loosen the 10 cylinder head set bolts in the order shown in the illustration. Remove the 10 cylinder head set bolts and 6 plate washers.

NOTICE:

- Be careful not to drop the plate washers into the cylinder head sub-assembly.

- Warpage or cracking of the cylinder head sub-assembly may result from removing the cylinder head set bolts in the incorrect order.

HINT:

Arrange the removed parts in such a way that they can be reinstalled to their original locations.

(2) Remove the cylinder head sub-assembly from the cylinder block sub-assembly.

51. REMOVE CYLINDER HEAD GASKET

Click here

.gif)

.gif)

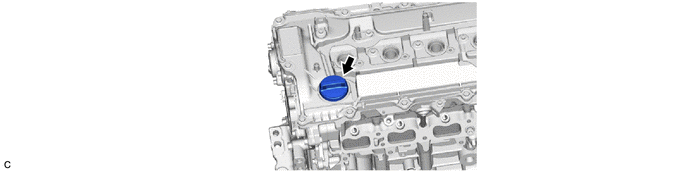

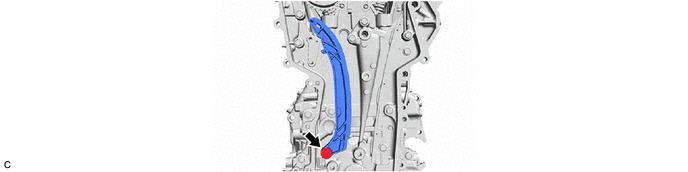

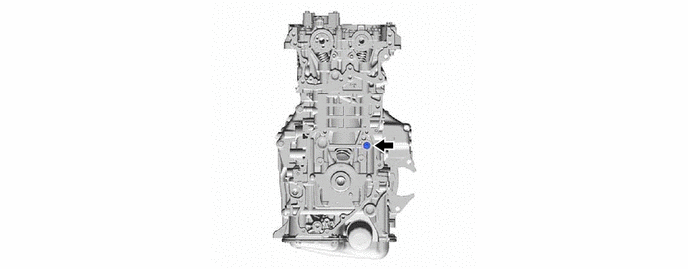

52. REMOVE CYLINDER BLOCK WATER JACKET SPACER

.png) |

NOTICE: Be sure to remove the cylinder block water jacket spacer. If it is not removed, it may fall and become damaged when the cylinder block sub-assembly is inverted. |

53. REMOVE OIL FILTER SUB-ASSEMBLY

Click here .gif)

54. REMOVE OIL FILTER UNION

(1) Using a 12 mm hexagon socket wrench, remove the oil filter union from the stiffening crankcase assembly.

55. REMOVE OIL PAN DRAIN PLUG

56. REMOVE OIL PAN SUB-ASSEMBLY

|

*a | Nut |

- | - |

(1) Remove the 10 bolts and 2 nuts.

(2) Insert the blade of an oil pan seal cutter between the oil pan sub-assembly and stiffening crankcase assembly, cut through the applied sealer and remove the oil pan sub-assembly.

NOTICE:

- Be careful not to damage the contact surfaces of the stiffening crankcase assembly and oil pan sub-assembly.

- Be careful not to damage the oil pan sub-assembly flange.

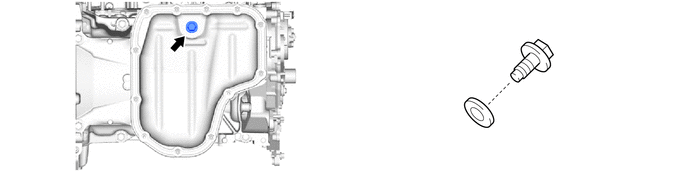

57. REMOVE OIL STRAINER SUB-ASSEMBLY

(1) Using an 8 mm socket wrench, remove the bolt, oil strainer sub-assembly and oil strainer gasket from the stiffening crankcase assembly.

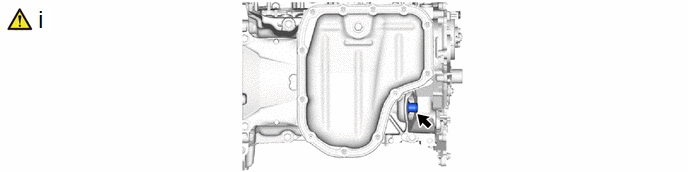

58. REMOVE ENGINE OIL LEVEL SENSOR

.png) |

Click here |

59. REMOVE OIL PUMP ASSEMBLY

Click here

.gif)

.gif)

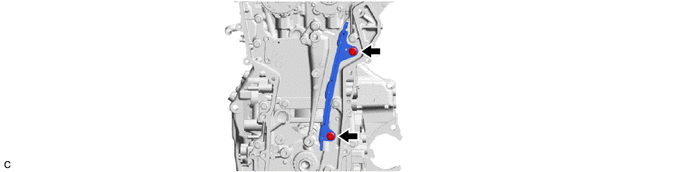

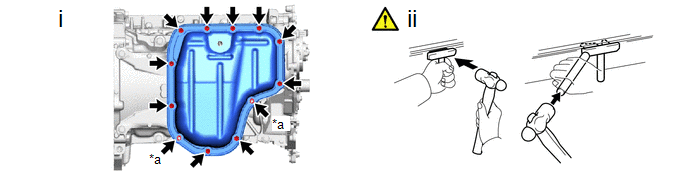

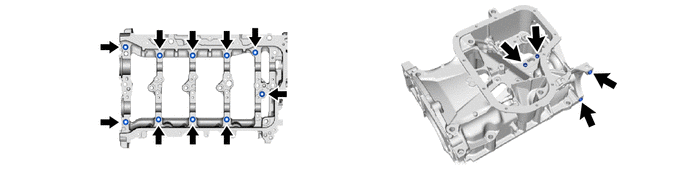

60. REMOVE STIFFENING CRANKCASE ASSEMBLY

(1) Remove the 10 bolts.

(2) Using a screwdriver, remove the stiffening crankcase assembly by prying between the stiffening crankcase assembly and cylinder block sub-assembly at the places shown in the illustration.

NOTICE:

Be careful not to damage the contact surfaces of the cylinder block sub-assembly and stiffening crankcase assembly.

HINT:

Tape the screwdriver tip before use.

61. REMOVE STRAIGHT SCREW PLUG

(1) Using a 10 mm hexagon socket wrench, remove the straight screw plug and gasket from the stiffening crankcase assembly.

62. REMOVE REAR ENGINE OIL SEAL

63. REMOVE WIRE HARNESS CLAMP BRACKET

64. REMOVE STUD BOLT

.png) |

NOTICE: If a stud bolt is deformed or its threads are damaged, replace it. |

65. REMOVE RING PIN

.png) |

NOTICE: It is not necessary to remove the ring pins unless they are being replaced. |

66. REMOVE STRAIGHT PIN

.png) |

NOTICE: It is not necessary to remove the straight pins unless they are being replaced. |