Toyota Corolla Cross: Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

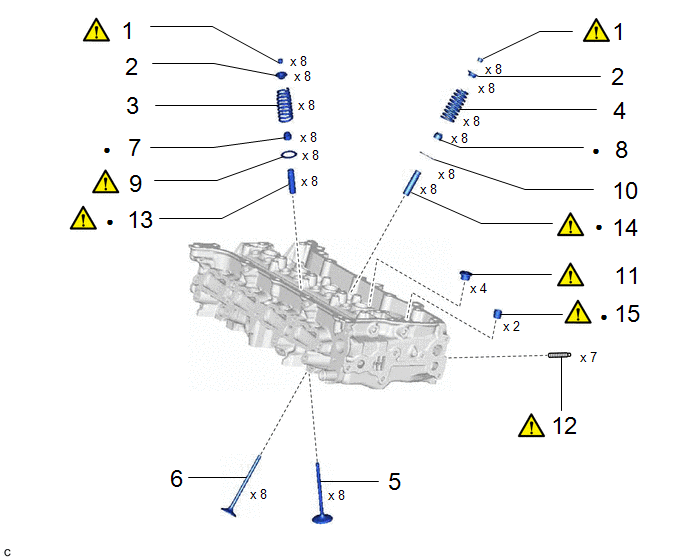

COMPONENTS (DISASSEMBLY)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | VALVE SPRING RETAINER LOCK |

13741A |

|

- | - |

|

2 | VALVE SPRING RETAINER |

13741B | - |

- | - |

|

3 | INTAKE VALVE COMPRESSION SPRING |

13711M | - |

- | - |

|

4 | EXHAUST VALVE COMPRESSION SPRING |

13715H | - |

- | - |

|

5 | INTAKE VALVE |

13711 | - |

- | - |

|

6 | EXHAUST VALVE |

13715 | - |

- | - |

|

7 | INTAKE VALVE STEM OIL SEAL |

13711E | - |

- | - |

|

8 | EXHAUST VALVE STEM OIL SEAL |

13715A | - |

- | - |

|

9 | INTAKE VALVE SPRING SEAT |

13734A |

|

- | - |

|

10 | EXHAUST VALVE SPRING SEAT |

13734B | - |

- | - |

|

11 | NO. 1 STRAIGHT SCREW PLUG |

11117E |

|

- | - |

|

12 | STUD BOLT |

- |

|

- | - |

|

13 | INTAKE VALVE GUIDE BUSH |

11122 |

|

- | - |

|

14 | EXHAUST VALVE GUIDE BUSH |

11126 |

|

- | - |

|

15 | RING PIN |

11115A |

|

- | - |

|

● | Non-reusable part |

★ | Precoated part |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during cylinder head removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replaced Part or Performed Procedure |

Necessary Procedure | Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| Inspection After Repair |

|

|

PROCEDURE

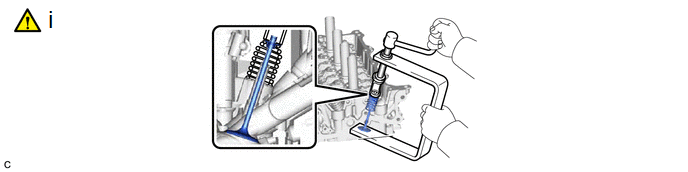

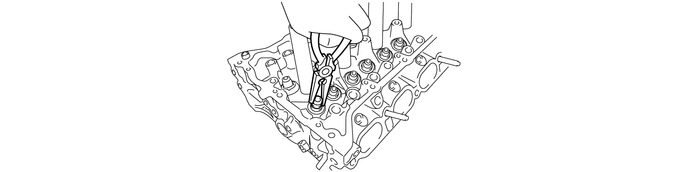

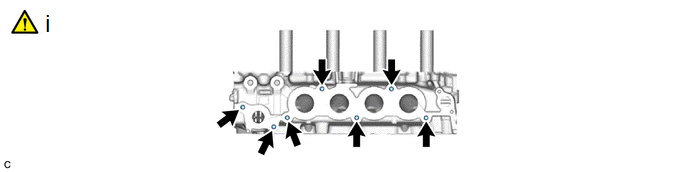

1. REMOVE VALVE SPRING RETAINER LOCK

(1) Using SST, compress each compression spring and remove the 16 valve spring retainer locks.

SST: 09202-70020

09202-01010

09202-01020

SST: 09202-00021

2. REMOVE VALVE SPRING RETAINER

3. REMOVE INTAKE VALVE COMPRESSION SPRING

4. REMOVE EXHAUST VALVE COMPRESSION SPRING

(a) Perform the same procedure as for the intake side.

5. REMOVE INTAKE VALVE

6. REMOVE EXHAUST VALVE

(a) Perform the same procedure as for the intake side.

7. REMOVE INTAKE VALVE STEM OIL SEAL

8. REMOVE EXHAUST VALVE STEM OIL SEAL

(a) Perform the same procedure as for the intake side.

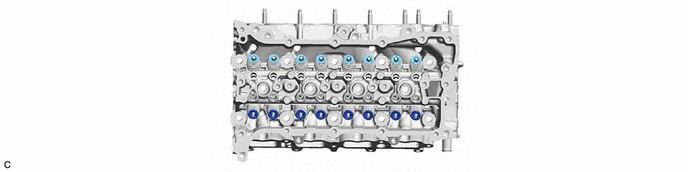

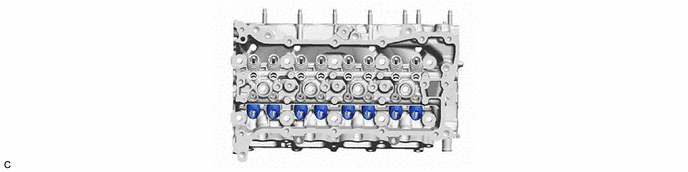

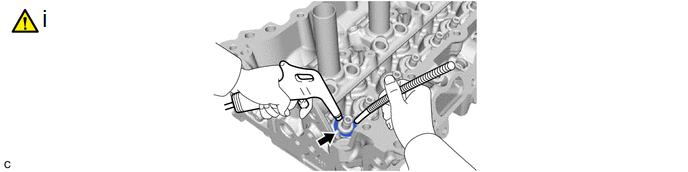

9. REMOVE INTAKE VALVE SPRING SEAT

(1) Using compressed air and a Magnet Hand, remove the 8 intake valve spring seats from the cylinder head sub-assembly by blowing air onto them.

10. REMOVE EXHAUST VALVE SPRING SEAT

(a) Perform the same procedure as for the intake side.

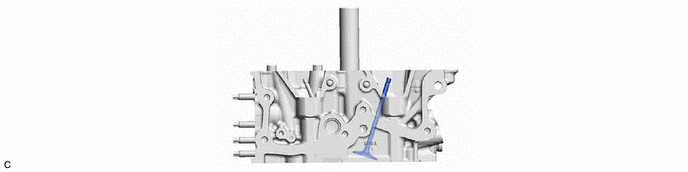

11. REMOVE NO. 1 STRAIGHT SCREW PLUG

.png) |

NOTICE: If coolant leaks from a No. 1 straight screw plug or a plug is corroded, replace it. |

(1) Using a 6 mm straight hexagon wrench, remove the 4 No. 1 straight screw plugs from the cylinder head sub-assembly.

12. REMOVE STUD BOLT

.png) |

NOTICE: If a stud bolt is deformed or its threads are damaged, replace it. |

(1) Using an E8 "TORX" socket wrench, remove the 7 stud bolts.

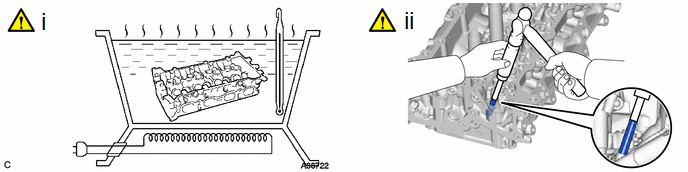

13. REMOVE INTAKE VALVE GUIDE BUSH

(1) Heat the cylinder head sub-assembly to between 80 and 100°C (176 and 212°F).

(2) Place the cylinder head sub-assembly on wooden blocks.

CAUTION:

Be sure to wear protective gloves.

(3) Using SST and a hammer, tap out the intake valve guide bush.

SST: 09201-01055

SST: 09950-70010

09951-07100

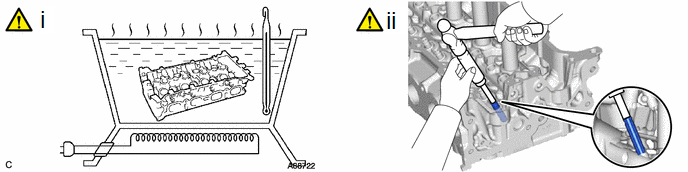

14. REMOVE EXHAUST VALVE GUIDE BUSH

(1) Heat the cylinder head sub-assembly to between 80 and 100°C (176 and 212°F).

(2) Place the cylinder head sub-assembly on wooden blocks.

CAUTION:

Be sure to wear protective gloves.

(3) Using SST and a hammer, tap out the exhaust valve guide bush.

SST: 09201-01055

SST: 09950-70010

09951-07100

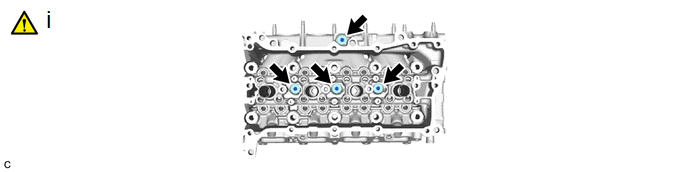

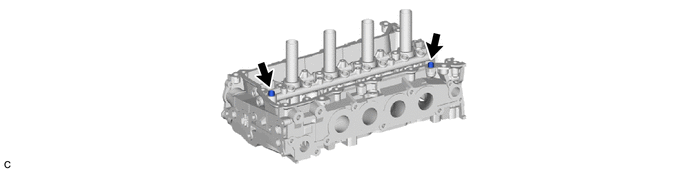

15. REMOVE RING PIN

.png) |

NOTICE: It is not necessary to remove the ring pins unless they are being replaced. |

.gif)