Toyota Corolla Cross: Camshaft Position "B" - Actuator Bank 1 Circuit Open (P001313)

DESCRIPTION

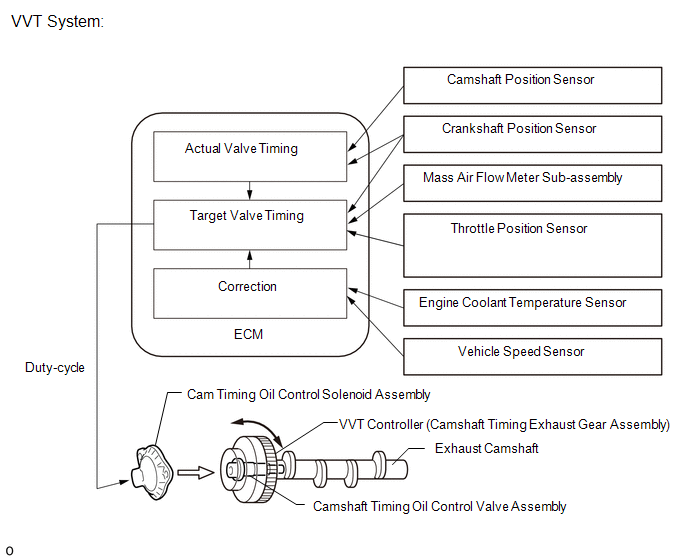

The Variable Valve Timing (VVT) system (for exhaust side) adjusts the exhaust valve timing to improve driveability. The engine oil pressure turns the VVT controller (camshaft timing exhaust gear assembly) to adjust the valve timing.

The cam timing oil control solenoid assembly operates according to signals received from the ECM to control the position of the camshaft timing oil control valve assembly (exhaust camshaft timing gear bolt assembly) and supply engine oil. The camshaft timing oil control valve assembly moves when the ECM applies 12 V to the cam timing oil control solenoid assembly. The ECM changes the energizing time of the cam timing oil control solenoid assembly (duty-cycle) in accordance with the camshaft position, crankshaft position, throttle position, etc.

|

DTC No. | Detection Item |

DTC Detection Condition | Trouble Area |

MIL | Note |

|---|---|---|---|---|---|

|

P001313 | Camshaft Position "B" - Actuator Bank 1 Circuit Open |

Open or short in cam timing oil control solenoid assembly circuit (1 trip detection logic). |

| Comes on |

|

MONITOR DESCRIPTION

This DTC is designed to detect an open or short in the cam timing oil control solenoid assembly circuit. If the cam timing oil control solenoid assembly duty-cycle is excessively high or low while the ignition switch is ON or the engine is running, the ECM will illuminate the MIL and store this DTC.

MONITOR STRATEGY

|

Related DTCs | P0013: Cam timing oil control solenoid assembly range check |

|

Required Sensors/Components (Main) | Cam timing oil control solenoid assembly |

|

Required Sensors/Components (Related) |

- |

| Frequency of Operation |

Continuous |

| Duration |

1 second |

| MIL Operation |

Immediate |

| Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

All|

Monitor runs whenever the following DTCs are not stored |

None |

| All of the following conditions are met |

- |

| Auxiliary battery voltage |

8 V or higher |

| Starter |

Off |

| Ignition switch |

ON |

| Time after ignition switch off to ON |

0.5 seconds or more |

|

Either of the following conditions is met |

A or B |

| A. Both of the following conditions are met |

- |

| Auxiliary battery voltage |

11 V or higher, and less than 13 V |

|

Target duty cycle | Less than 70% |

|

B. Both of the following conditions are met |

- |

| Auxiliary battery voltage |

13 V or higher |

| Target duty cycle |

Less than 80% |

|

All of the following conditions are met | - |

|

Current cut status | Not cut |

|

Target duty cycle | 25% or higher |

TYPICAL MALFUNCTION THRESHOLDS

Case 1|

Output duty cycle | 100% or higher |

|

Output duty cycle | 0% or less |

CONFIRMATION DRIVING PATTERN

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

Click here

.gif)

.gif)

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

Click here

.gif)

.gif)

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON.

- Turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Start the engine [A].

- Wait 5 seconds or more [B].

- Turn the GTS on.

- Enter the following menus: Powertrain / Engine / Trouble Codes [C].

- Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P001313.

- Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system has a malfunction.

- If the judgment result is INCOMPLETE, perform steps [A] through [C] again.

- [A] to [C]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the auxiliary battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Read Freeze Frame Data using the GTS. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

| 1. |

CLEAR DTC |

(a) Clear the DTC after recording the Freeze Frame Data and DTC.

Powertrain > Engine > Clear DTCs(b) Turn the ignition switch off and wait for at least 30 seconds.

|

| 2. |

READ OUTPUT DTC (DTC P001313) |

(a) Start the engine.

(b) Read the DTCs.

Powertrain > Engine > Trouble Codes|

Result | Proceed to |

|---|---|

|

DTCs are not output | A |

|

DTC P001313 is output |

B |

| A |

.gif) | CHECK FOR INTERMITTENT PROBLEMS |

|

| 3. |

INSPECT CAM TIMING OIL CONTROL SOLENOID ASSEMBLY |

Click here .gif)

| NG | .gif) | REPLACE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY |

|

| 4. |

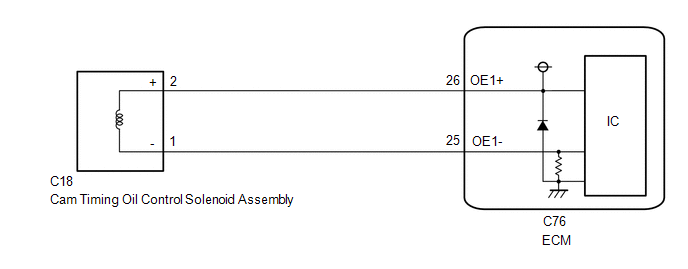

CHECK HARNESS AND CONNECTOR (CAM TIMING OIL CONTROL SOLENOID ASSEMBLY - ECM) |

(a) Disconnect the cam timing oil control solenoid assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

C18-2 (+) - C76-26 (OE1+) |

Always | Below 1 Ω |

|

C18-1 (-) - C76-25 (OE1-) |

Always | Below 1 Ω |

|

C18-2 (+) or C76-26 (OE1+) - Body ground and other terminals |

Always | 10 kΩ or higher |

|

C18-1 (-) or C76-25 (OE1-) - Body ground and other terminals |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE ECM

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)