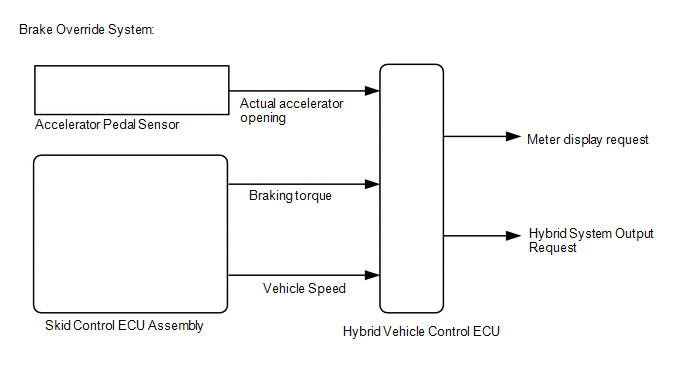

Toyota Corolla Cross: Brake Override System

DESCRIPTION

When the vehicle is being driven with the accelerator pedal depressed, depressing the brake pedal without releasing the accelerator pedal will activate the brake override system to restrict hybrid system output. The conditions for activating the brake override system as well as the items that are controlled are explained below.

Activation Conditions:

Activation Conditions:

- The accelerator pedal and brake pedal are depressed at the same time.

NOTICE:

Brake override control may not be performed depending on the relationship between accelerator opening and vehicle speed.

- Controls hybrid system output

HINT:

- When the control is operating, hybrid system output is controlled in accordance with the brake pedal stroke.

- When the hybrid system output is reduced because the accelerator pedal and brake pedal are depressed at the same time, an indicator is displayed on the meter. (Operation of the system can be confirmed when the indicator is displayed on the meter.)

- The accelerator pedal or brake pedal is released.

Drive at 10 km/h (6 mph), depress the accelerator pedal by 1/2 to 3/4 and keep it in that position. Under these conditions, if hybrid system output is controlled when the brake pedal is depressed by the left foot of the driver, it can be confirmed that the brake override system has operated.

CAUTION / NOTICE / HINT

CAUTION:

Perform this road test only in an appropriate safe location, in accordance with all local laws.

Pay careful attention to the surroundings when performing the road test.

HINT:

The brake override system restricts hybrid system output if the brake pedal is depressed when driving with the accelerator pedal depressed. If a customer reports experiencing a loss of power (requested accelerator torque) after the accelerator and brake pedals have both been intentionally depressed, explain that this is not a malfunction, and depressing both the accelerator and brake pedals at the same time should be avoided.

PROCEDURE

|

1. | CHECK DTC OUTPUT (HEALTH CHECK) |

(a) Enter the following menus: System Select / Health Check.

(b) Check for DTCs.

|

Result | Proceed to |

|---|---|

|

No DTCs are output. |

A |

| DTCs are output. |

B |

(c) Turn the ignition switch off.

| B | .gif) | GO TO DTC CHART |

|

|

2. | READ VALUE USING GTS (MASTER CYLINDER CONTROL TORQUE) |

(a) Read the value displayed on the GTS.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

Master Cylinder Control Torque |

|

Result | Proceed to |

|---|---|

|

Display changes according to brake pedal depression force |

A |

| Other than above |

B |

(b) Turn the ignition switch off.

| B | .gif) | CHECK BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY |

|

|

3. | READ VALUE USING GTS (ACCELERATOR POSITION SENSOR NO. 1 VOLTAGE %, ACCELERATOR POSITION SENSOR NO. 2 VOLTAGE %) |

(a) Read the values displayed on the GTS.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

Accelerator Position Sensor No.1 Voltage % |

|

Accelerator Position Sensor No.2 Voltage % |

Standard:

|

Inspection Condition |

Specified Condition |

|---|---|

|

Accelerator pedal fully released → fully depressed |

Value (%) changes with accelerator pedal operation |

(b) Turn the ignition switch off.

| NG | .gif) | REPLACE ACCELERATOR PEDAL(W/SENSOR) ROD ASSEMBLY |

|

|

4. | READ VALUE USING GTS (VEHICLE SPEED) |

(a) Read the value displayed on the GTS.

Powertrain > Hybrid Control > Data List|

Tester Display |

|---|

|

Vehicle Speed |

Standard:

|

Inspection Condition |

Specified Condition |

|---|---|

|

Vehicle stopped | 0 km/h (0 mph) |

|

Vehicle being driven at a constant speed (16 to 64 km/h (10 to 40 mph)) |

No large fluctuations in displayed speed |

CAUTION:

Perform this road test only in an appropriate safe location, in accordance with all local laws.

HINT:

Data can be captured relatively easily by using the snapshot function in the Data List. Confirm the data after performing the drive test.

(b) Turn the ignition switch off.

| NG | .gif) | GO TO METER / GAUGE SYSTEM (SPEED SIGNAL CIRCUIT) |

|

|

5. | READ VALUE USING GTS (FR, FL, RR, RL WHEEL SPEED) |

(a) Read the values displayed on the GTS.

Chassis > Brake/EPB > Data List|

Tester Display |

|---|

|

FR Wheel Speed |

|

FL Wheel Speed |

|

RR Wheel Speed |

|

RL Wheel Speed |

Standard:

|

Inspection Condition |

Specified Condition |

|---|---|

|

Vehicle stopped | 0 km/h (0 mph) |

|

Vehicle being driven at a constant speed (16 to 64 km/h (10 to 40 mph)) |

No large fluctuations in displayed speed |

CAUTION:

Perform this road test only in an appropriate safe location, in accordance with all local laws.

HINT:

Data can be captured relatively easily by using the snapshot function in the Data List. Confirm the data after performing the drive test.

(b) Turn the ignition switch off.

| OK | .gif) | END |

| NG | .gif) | INSPECT FRONT OR REAR SPEED SENSOR |

.gif)