Toyota Corolla Cross: Brake Booster (Skid Control ECU) Communication Stop Mode

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

|---|---|---|

|

Brake Booster (Skid Control ECU) Communication Stop Mode |

Communication stop for "Brake Booster" is indicated on the "Communication Bus Check" screen of the GTS. Click here |

|

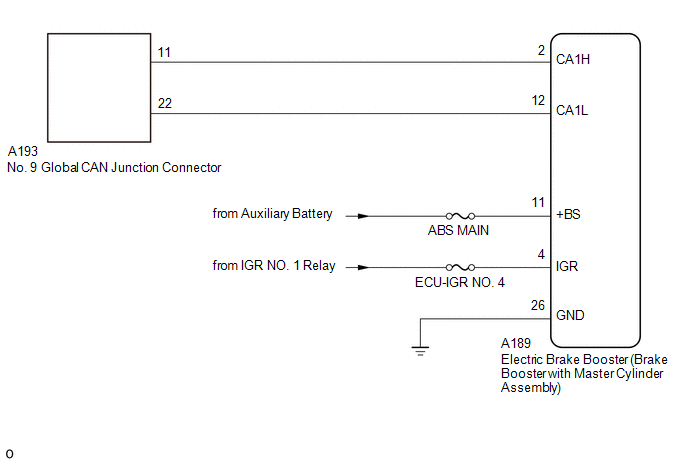

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

- Because the order of diagnosis is important to allow correct diagnosis,

make sure to begin troubleshooting using How to Proceed with Troubleshooting

when CAN communication system related DTCs are output.

Click here

.gif)

- Before measuring the resistance of the CAN bus, turn the ignition switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) auxiliary battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- After the ignition switch is turned off, there may be a waiting time before

disconnecting the negative (-) auxiliary battery terminal.

Click here

.gif)

- When disconnecting and reconnecting the auxiliary battery.

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

.gif)

- Some parts must be initialized and set when replacing or removing and installing

parts.

Click here

.gif)

- After performing repairs, perform the DTC check procedure and confirm that

the DTCs are not output again.

DTC check procedure: Turn the ignition switch to ON and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

- After the repair, perform the CAN bus check and check that all the ECUs

and sensors connected to the CAN communication system are displayed as normal.

Click here

.gif)

- Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

- Before disconnecting related connectors for inspection, push in on each connector body to check that the connector is not loose or disconnected.

- When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE

|

1. |

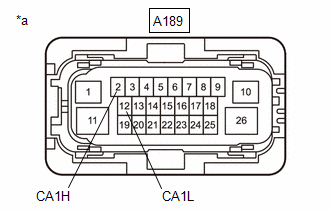

CHECK FOR OPEN IN CAN BUS LINES (ELECTRIC BRAKE BOOSTER (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY) BRANCH LINE) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

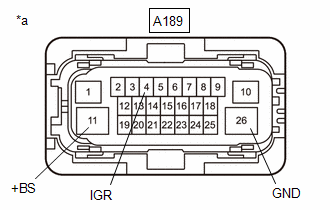

(b) Disconnect the electric brake booster (brake booster with master cylinder assembly) connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG | .gif) |

REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (ELECTRIC BRAKE BOOSTER (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY)) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) auxiliary battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A189-11 (+BS) - Body ground |

Ignition switch off |

11 to 14 V |

|

A189-4 (IGR) - Body ground |

Ignition switch ON |

11 to 14 V |

| OK | .gif) |

REPLACE ELECTRIC BRAKE BOOSTER (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY) |

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

.gif)