Toyota Corolla Cross: Washer Fluid Level Warning Switch Circuit

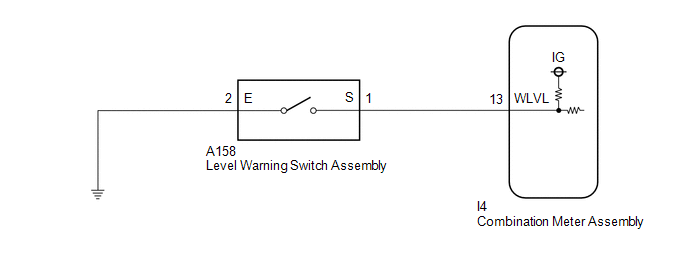

DESCRIPTION

When the washer fluid level is lower than a certain level, a warning message is displayed on the combination meter assembly.

WIRING DIAGRAM

PROCEDURE

| 1. |

READ VALUE USING GTS (COMBINATION METER) |

(a) Read the Data List according to the display on the GTS.

Body Electrical > Combination Meter > Data List|

Tester Display | Measurement Item |

Range | Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Washer Level Warning Switch |

Washer fluid level warning switch |

OFF or ON | OFF: Washer fluid level not low ON: Washer fluid level low |

- |

|

Tester Display |

|---|

| Washer Level Warning Switch |

OK:

The GTS display changes correctly in response to the washer fluid level.

| OK | .gif) | REPLACE COMBINATION METER ASSEMBLY |

|

| 2. |

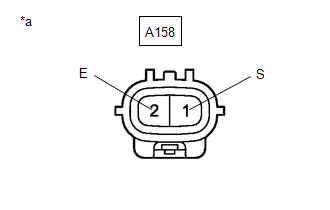

INSPECT LEVEL WARNING SWITCH ASSEMBLY |

HINT:

This check should be performed with the level warning switch assembly installed on the washer jar.

(a) Remove the level warning switch assembly.

| (b) Fill the washer jar with washer fluid. |

|

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A158-1 (S) - A158-2 (E) |

Fluid volume is 600 to 800 cc (36.6 to 48.8 cu.in.) or higher* |

10 kΩ or higher |

|

Fluid volume is 600 to 800 cc (36.6 to 48.8 cu.in.) or lower* |

Below 1 Ω |

HINT:

*: The level warning switch assembly begins operating when the fluid volume is 600 to 800 cc (36.6 to 48.8 cu.in.) depending on the vehicle condition.

| NG | .gif) | REPLACE LEVEL WARNING SWITCH ASSEMBLY |

|

| 3. |

CHECK HARNESS AND CONNECTOR (LEVEL WARNING SWITCH ASSEMBLY - COMBINATION METER ASSEMBLY) |

(a) Disconnect the I4 combination meter assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A158-1 (S) - I4-13 (WLVL) |

Always | Below 1 Ω |

|

A158-1 (S) or I4-13 (WLVL) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (LEVEL WARNING SWITCH ASSEMBLY - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A158-2 (E) - Body ground |

Always | Below 1 Ω |

| OK | .gif) | REPLACE COMBINATION METER ASSEMBLY |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)