Toyota Corolla Cross: Transmission Control Switch Circuit

DESCRIPTION

After moving the shift lever to M, it is possible to change the shift range between M1 and M10 using the shift lever. Moving the shift lever to "+" once raises the shift range by one, and moving the shift lever to "-" lowers the shift range by one.

WIRING DIAGRAM

.png)

CAUTION / NOTICE / HINT

NOTICE:

- Perform registration and/or initialization when parts related to the continuously

variable transaxle system are replaced.

Click here

.gif)

- Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

CHECK DTC OUTPUT |

(a) Enter the following menus:

Powertrain > Transmission > Trouble Codes(b) Read the DTCs using the GTS.

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTCs are output |

B |

| B | .gif) |

GO TO DTC CHART |

|

|

2. |

READ VALUE USING GTS (SHIFT SW STATUS (S RANGE)) |

(a) Enter the following menus:

(b) According to the display on the GTS, read the Data List.

Powertrain > Transmission > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Shift SW Status (S Range) |

Transmission control switch status |

ON or OFF |

|

- |

|

Tester Display |

|---|

|

Shift SW Status (S Range) |

|

Result |

Proceed to |

|---|---|

|

Data List value is normal |

A |

|

Data List value is not normal |

B |

| B | .gif) |

GO TO STEP 8 |

|

|

3. |

READ VALUE USING GTS (SPORT SHIFT UP SW AND SPORT SHIFT DOWN SW) |

(a) Enter the following menus:

(b) According to the display on the GTS, read the Data List.

Powertrain > Transmission > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Sport Shift Up SW |

Sport shift up switch status |

ON or OFF |

|

- |

|

Sport Shift Down SW |

Sport shift down switch status |

ON or OFF |

|

- |

|

Tester Display |

|---|

|

Sport Shift Up SW |

|

Sport Shift Down SW |

|

Result |

Proceed to |

|---|---|

|

Data List values are normal |

A |

|

Data List values are not normal |

B |

| A | .gif) |

CHECK FOR INTERMITTENT PROBLEMS Click here Click here |

|

|

4. |

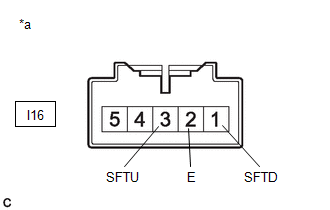

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

(a) Disconnect the shift lock control unit assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (SFTU) - 2 (E) |

Shift lever held in "+" |

Below 1 Ω |

|

3 (SFTU) - 2 (E) |

Shift lever in M |

10 kΩ or higher |

|

1 (SFTD) - 2 (E) |

Shift lever held in "-" |

Below 1 Ω |

|

1 (SFTD) - 2 (E) |

Shift lever in M |

10 kΩ or higher |

(c) Connect the shift lock control unit assembly connector.

| NG | .gif) |

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY |

|

|

5. |

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - BODY GROUND) |

(a) Disconnect the I16 shift lock control unit assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I16-2 (E) - Body ground |

Always |

Below 1 Ω |

(c) Connect the I16 shift lock control unit assembly connector.

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - BODY GROUND) |

|

|

6. |

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - TCM) |

(a) Disconnect the C80 TCM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C80-28 (SFTU) - Body ground |

Shift lever held in "+" |

Below 1 Ω |

|

C80-28 (SFTU) - Body ground |

Shift lever in M |

10 kΩ or higher |

|

C80-27 (SFTD) - Body ground |

Shift lever held in "-" |

Below 1 Ω |

|

C80-27 (SFTD) - Body ground |

Shift lever in M |

10 kΩ or higher |

(c) Connect the C80 TCM connector.

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - TCM) |

|

|

7. |

REPLACE TCM |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

8. |

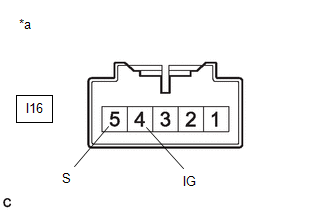

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (TRANSMISSION CONTROL SWITCH) |

|

(a) Disconnect the shift lock control unit assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4 (IG) - 5 (S) |

Shift lever in M |

Below 1 Ω |

|

4 (IG) - 5 (S) |

Shift lever not in M |

10 kΩ or higher |

(c) Connect the shift lock control unit assembly connector.

| NG | .gif) |

REPLACE SHIFT LOCK CONTROL UNIT ASSEMBLY |

|

|

9. |

INSPECT SHIFT LOCK CONTROL UNIT ASSEMBLY (POWER SOURCE) |

.png)

|

*a |

Front view of wire harness connector (to Shift Lock Control Unit Assembly (Transmission Control Switch)) |

(a) Disconnect the I16 shift lock control unit assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I16-4 (IG) - Body ground |

Ignition switch ON |

11 to 14 V |

|

I16-4 (IG) - Body ground |

Ignition switch off |

Below 1 V |

(c) Connect the I16 shift lock control unit assembly connector.

| NG | .gif) |

CHECK POWER SOURCE CIRCUIT (SHIFT LOCK CONTROL UNIT ASSEMBLY) |

|

|

10. |

CHECK HARNESS AND CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - TCM) |

(a) Disconnect the C80 TCM connector.

(b) Disconnect the I16 shift lock control unit assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I16-5 (S) - C80-14 (S) |

Always |

Below 1 Ω |

|

I16-5 (S) or C80-14 (S) - Body ground and other terminals |

Always |

10 kΩ or higher |

(d) Connect the C80 TCM connector.

(e) Connect the I16 shift lock control unit assembly connector.

| NG | .gif) |

REPAIR OR REPLACE HARNESS OR CONNECTOR (SHIFT LOCK CONTROL UNIT ASSEMBLY - TCM) |

|

|

11. |

REPLACE TCM |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

.gif)