Toyota Corolla Cross: Tire Pressure Monitor Transmitter ID 1 Missing Message (C214187-C214487)

DESCRIPTION

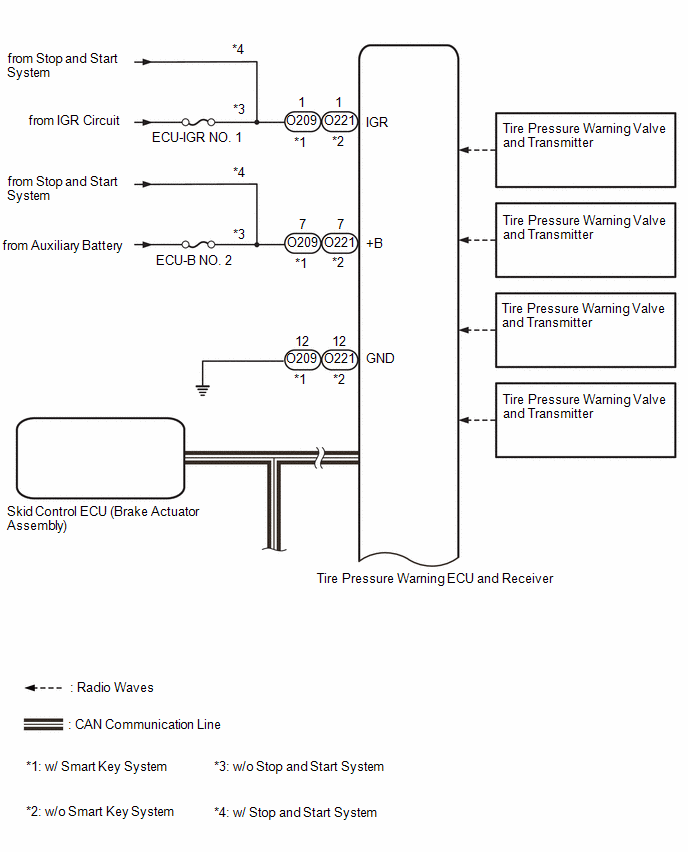

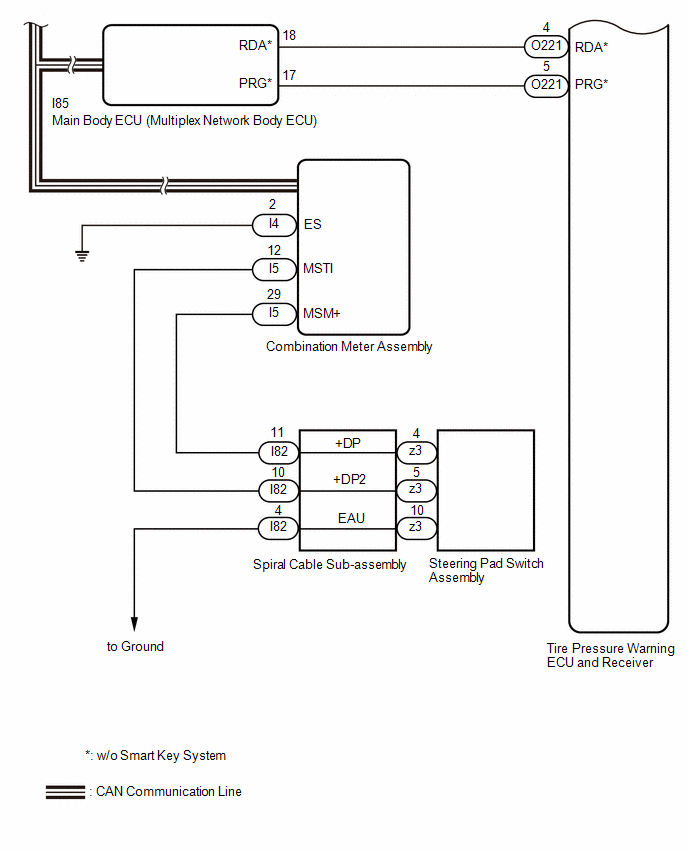

The tire pressure warning valve and transmitters that are installed in the tire and wheel assemblies measure the tire pressure of each wheel. The measured values are transmitted to the tire pressure warning ECU and receiver in the vehicle as radio waves. The ECU compares the measured tire pressure values with the tire pressure threshold. When the measured tire pressure value is less than this threshold, the warning light in the combination meter assembly illuminates.

The tire pressure warning valve and transmitters constantly send radio waves to the tire pressure warning ECU and receiver.

Under the conditions below, the tire pressure warning ECU and receiver is unable to receive the signals from the tire pressure warning valve and transmitters, and a DTC is stored.

- Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

- Devices using similar radio frequencies are used in the vehicle.

- The ID of a tire pressure warning valve and transmitter is mistyped during registration.

- A tire, wheel and/or transmitter from a different vehicle is installed.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C214187 |

Tire Pressure Monitor Transmitter ID 1 Missing Message |

When driving at 40 km/h (25 mph) or higher, the tire pressure warning ECU and receiver cannot receive radio waves from the tire pressure warning valve and transmitter for a total of approximately 20 minutes |

|

|

C214287 |

Tire Pressure Monitor Transmitter ID 2 Missing Message |

When driving at 40 km/h (25 mph) or higher, the tire pressure warning ECU and receiver cannot receive radio waves from the tire pressure warning valve and transmitter for a total of approximately 20 minutes |

|

|

C214387 |

Tire Pressure Monitor Transmitter ID 3 Missing Message |

When driving at 40 km/h (25 mph) or higher, the tire pressure warning ECU and receiver cannot receive radio waves from the tire pressure warning valve and transmitter for a total of approximately 20 minutes |

|

|

C214487 |

Tire Pressure Monitor Transmitter ID 4 Missing Message |

When driving at 40 km/h (25 mph) or higher, the tire pressure warning ECU and receiver cannot receive radio waves from the tire pressure warning valve and transmitter for a total of approximately 20 minutes |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the tire pressure warning ECU and receiver, first use the GTS to record all of the current IDs and registered tires with transmitters of the tire pressure warning valve and transmitter registered to the tire pressure warning ECU and receiver.

- It is necessary to perform initialization after registration of the transmitter

IDs into the tire pressure warning ECU and receiver if the ECU and/or one of

the valve and transmitters has been replaced.

for Registration:

Click here

.gif)

for Initialization:

Click here

.gif)

PROCEDURE

|

1. |

CHECK FREQUENCY RECEIVING CONDITION |

(a) Check that the following conditions are not met:

(1) Facilities or devices that use similar radio frequencies are located in the vicinity of the vehicle.

HINT:

If the vehicle is located in an area such as the one described above, the tire pressure warning light may illuminate after blinking for 1 minute due to interfering radio frequencies.

(2) Devices using similar radio frequencies are used in the vehicle.

HINT:

Radio transmissions may be interrupted due to the surroundings or devices installed by the user.

|

Result |

Proceed to |

|---|---|

|

There is no device or facility that uses radio waves of approximately the same frequency in the vicinity of the vehicle or inside the vehicle. |

A |

|

There is a device or facility that uses radio waves of approximately the same frequency in the vicinity of the vehicle or inside the vehicle. |

B |

| B | .gif) |

GO TO STEP 9 |

|

|

2. |

CONFIRM OUTPUT DTC |

(a) Check the stored DTC.

Chassis > Tire Pressure Monitor > Trouble Codes|

Result |

Proceed to |

|---|---|

|

Any DTCs from C214187 to C214487 are output |

A |

|

All DTCs from C214187 to C214487 are output |

B |

| B | .gif) |

GO TO STEP 8 |

|

|

3. |

IDENTIFY TRANSMITTER CORRESPONDING TO DTC (TIRE POSITION) |

(a) Display the "ID Tire Position" value for each wheel using the GTS.

(b) Refer to the following chart and check the wheel position of the DTC and transmitter match.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

ID 1 Tire Position |

ID1 tire position |

No Information, FL, FR, RL, RR, Spare or Judging |

ID1 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 2 Tire Position |

ID2 tire position |

No Information, FL, FR, RL, RR, Spare or Judging |

ID2 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 3 Tire Position |

ID3 tire position |

No Information, FL, FR, RL, RR, Spare or Judging |

ID3 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

ID 4 Tire Position |

ID4 tire position |

No Information, FL, FR, RL, RR, Spare or Judging |

ID4 tire position is displayed |

If no tire position information is stored, "No Information" will be displayed. |

|

Tester Display |

|---|

|

ID 1 Tire Position |

|

ID 2 Tire Position |

|

ID 3 Tire Position |

|

ID 4 Tire Position |

|

|

4. |

CHECK TRANSMITTER ID |

(a) Refer to the following chart and record the tire pressure warning valve and transmitter ID of the output DTC.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code |

Registered ID1 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID1 displayed |

- |

|

Registered ID 2 Code |

Registered ID2 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID2 displayed |

- |

|

Registered ID 3 Code |

Registered ID3 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID3 displayed |

- |

|

Registered ID 4 Code |

Registered ID4 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID4 displayed |

- |

HINT:

*: Displayed only when the ID No. is not registered.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

|---|

|

Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

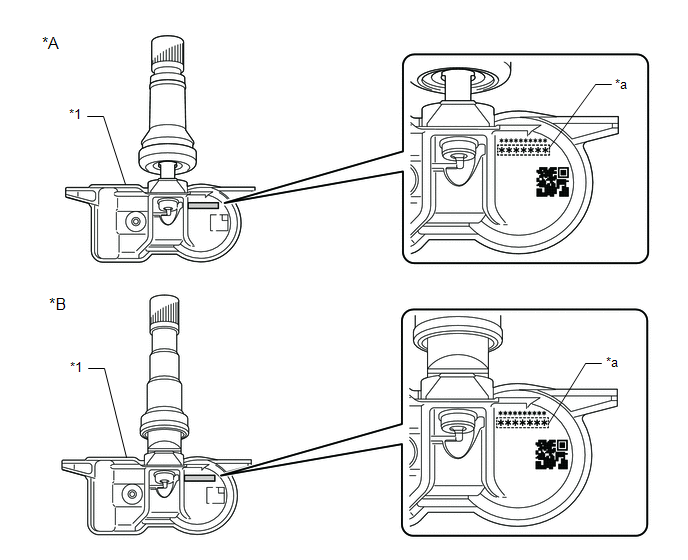

(b) Disassemble the tire indicated in the output DTC and check the tire pressure warning valve and transmitter ID.

|

*A |

for Aluminum Wheel Type |

*B |

for Steel Wheel Type |

|

*1 |

Tire Pressure Warning Valve and Transmitter |

- |

- |

|

*a |

Transmitter ID (7-digit Number) |

- |

- |

(c) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result |

Proceed to |

|---|---|

|

Match |

A |

|

Do not match |

B |

| A | .gif) |

REPLACE CORRESPONDING TIRE PRESSURE WARNING VALVE AND TRANSMITTER for Aluminum Wheel Type: Click here for Steel Wheel Type: Click here |

|

|

5. |

REGISTRATION OF TRANSMITTER ID |

Click here .gif)

|

|

6. |

PERFORM INITIALIZATION |

Click here .gif)

|

|

7. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Tire Pressure Monitor > Clear DTCs| NEXT | .gif) |

END |

|

8. |

CHECK TIRE PRESSURE WARNING VALVE AND TRANSMITTER |

(a) Refer to the following chart and record all of the tire pressure warning valve and transmitter IDs.

Chassis > Tire Pressure Monitor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Registered ID 1 Code |

Registered ID1 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID1 displayed |

- |

|

Registered ID 2 Code |

Registered ID2 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID2 displayed |

- |

|

Registered ID 3 Code |

Registered ID3 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID3 displayed |

- |

|

Registered ID 4 Code |

Registered ID4 code |

min.: 0 max.: FFFFFFF* |

ID No. registered for transmitter ID4 displayed |

- |

HINT:

- *: Displayed only when the ID No. is not registered.

- The wheel position cannot be determined from ID1 through ID4 on the Data List.

|

Tester Display |

|---|

|

Registered ID 1 Code |

|

Registered ID 2 Code |

|

Registered ID 3 Code |

|

Registered ID 4 Code |

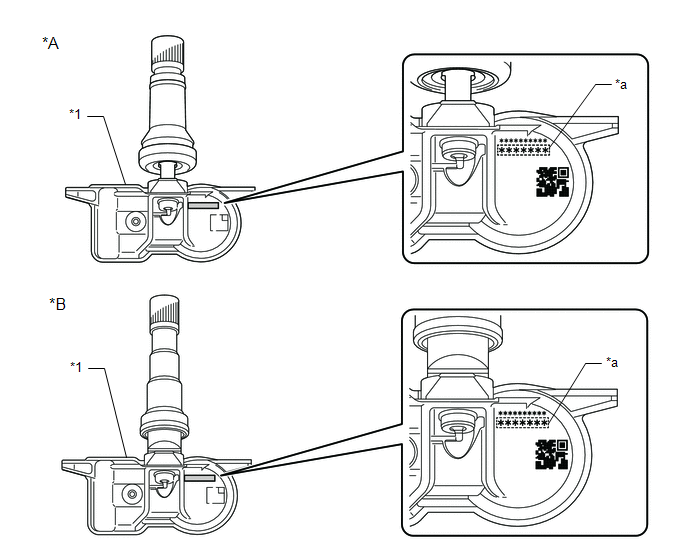

(b) Disassemble all of the tires and check the tire pressure warning valve and transmitter IDs.

|

*A |

for Aluminum Wheel Type |

*B |

for Steel Wheel Type |

|

*1 |

Tire Pressure Warning Valve and Transmitter |

- |

- |

|

*a |

Transmitter ID (7-digit Number) |

- |

- |

(c) Confirm that the ID number on the transmitter and recorded transmitter ID match.

|

Result |

Proceed to |

|---|---|

|

Match |

A |

|

Do not match |

B |

| A | .gif) |

REPLACE TIRE PRESSURE WARNING ECU AND RECEIVER |

| B | .gif) |

GO TO STEP 5 |

|

9. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Tire Pressure Monitor > Clear DTCs| NEXT | .gif) |

END Explain to the customer that there is a high possibility that a device (located near or inside the vehicle) or facility using radio waves of approximately the same frequency is causing radio wave interference. |

.gif)