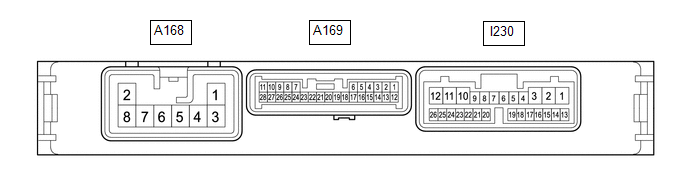

Toyota Corolla Cross: Terminals Of Ecu

TERMINALS OF ECU

ENGINE STOP AND START ECU

(a) Disconnect the engine stop and start ECU connectors.

(b) Measure the resistance and voltage according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A168-1 (BIN2) - Body ground |

Auxiliary battery | Always |

9.5 to 14 V |

|

A168-2 (GND2) - Body ground |

Ground | Always |

Below 1 Ω |

|

A168-3 (BIN1) - Body ground |

Auxiliary battery | Always |

9.5 to 14 V |

|

A168-8 (GND1) - Body ground |

Ground | Always |

Below 1 Ω |

|

A169-1 (+B) - Body ground |

Power source of engine stop and start ECU |

Ignition switch ON | 9.5 to 14 V |

|

A169-6 (DGND) - Body ground |

Ground | Always |

Below 1 Ω |

|

A169-10 (NE) - Body ground |

Engine speed signal from ECM |

Always | 10 kΩ or higher |

|

I230-13 (CANH) - Body ground |

CAN communication | Always |

200 Ω or higher |

|

I230-14 (CANL) - Body ground |

CAN communication | Always |

200 Ω or higher |

|

I230-15 (LC1H) - Body round |

Local bus communication line |

Always | 200 Ω or higher |

|

I230-16 (LC1L) - Body round |

Local bus communication line |

Always | 200 Ω or higher |

|

I230-18 (IGP) - Body ground |

Ignition switch signal |

Ignition switch ON | 9.5 to 14 V |

|

I230-19 (ACC) - Body ground |

Ignition switch signal |

Ignition switch ACC | 9.5 to 14 V |

|

I230-21 (IGR) - Body ground |

Ignition switch signal |

Ignition switch ON | 9.5 to 14 V |

(c) Reconnect the engine stop and start ECU connectors.

(d) Measure the resistance, voltage and pulse according to the value(s) in the table below.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A168-6 (OP21) - A169-6 (DGND) |

Oil pump with motor assembly drive power source signal |

One of the following conditions is met:

| 10.5 to 16 V |

|

A169-3 (BRE2) - Body ground | Ground (vacuum sensor assembly) |

Always | Below 1 Ω |

|

A169-7 (BNT1) - A169-6 (DGND) |

Engine hood courtesy switch (hood lock with courtesy light switch assembly) signal |

| Below 1.5 V |

| 8 to 14 V | ||

|

A169-9 (OPMI) - A169-6 (DGND) |

Oil pump with motor assembly directions signal |

One of the following conditions is met:

| Pulse generation (See waveform 1) |

|

A169-10 (NE) - A169-6 (DGND) | Engine speed signal from ECM |

Idling after engine warmed up |

Pulse generation (See waveform 2) |

|

A169-13 (PB) - A169-3 (BRE2) |

Vacuum sensor assembly signal |

| 1.6 to 2.0 V |

| 2.2 to 2.6 V | ||

| 3.4 to 3.8 V | ||

|

A169-14 (BRVC) - A169-6 (DGND) | Vacuum sensor assembly power supply |

| 4.5 to 5.5 V |

|

A169-17 (CLL) - A169-6 (DGND) |

Park/Neutral position switch assembly signal |

| 8 to 14 V |

| Below 3.0 V | ||

|

A169-19 (DON2) - A169-6 (DGND)*1 |

External backup boost converter (eco run vehicle converter assembly) signal |

Engine running | Pulse generation (see waveform 3) |

|

A169-21 (STA) - A169-6 (DGND) | Starter pinion operation signal |

Cranking | 6.0 V or more |

|

A169-27 (NOPM) - A169-6 (DGND) |

Oil pump with motor assembly speed signal |

One of the following conditions is met:

| Pulse generation (See waveform 4) |

|

I230-23 (IG31) - A169-6 (DGND) | Backup boost converter signal |

Ignition switch ON | 10.5 to 16 V |

|

I230-2 (B41) - A169-6 (DGND) |

Backup boost converter signal |

Always | 10.5 to 16 V |

|

I230-3 (IG41) - A169-6 (DGND) |

Backup boost converter signal |

Ignition switch ON | 10.5 to 16 V |

|

I230-5 (ECAN) - A169-6 (DGND) |

Stop and start system cancel switch (combination switch assembly) signal |

| Below 1.5 V |

| 8 to 14 V | ||

|

I230-10 (IG12) - A169-6 (DGND) | Backup boost converter signal |

Ignition switch ON | 10.5 to 16 V |

|

I230-18 (IGP) - A169-6 (DGND) |

Ignition switch signal |

Ignition switch ACC | Below 1 V |

|

Ignition switch ON | 9.5 to 14 V | ||

|

I230-19 (ACC) - A169-6 (DGND) |

Ignition switch signal | Ignition switch off |

Below 1 V |

| Ignition switch ACC |

9.5 to 14 V | ||

|

I230-21 (IGR) - A169-6 (DGND) |

Ignition switch signal | Ignition switch ACC |

Below 1 V |

| Ignition switch ON |

9.5 to 14 V |

- *1: for 9 Speakers

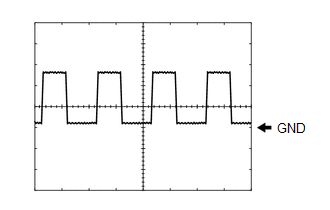

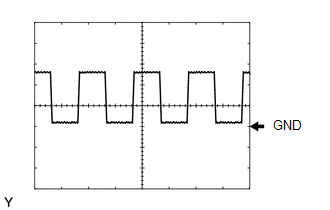

(e) Waveform 1

|

Item | Content |

|---|---|

|

Tester Connection | A169-9 (OPMI) - A169-6 (DGND) |

|

Tool Setting | 5 V/DIV., 5 ms./DIV. |

|

Condition | One of the following conditions is met:

|

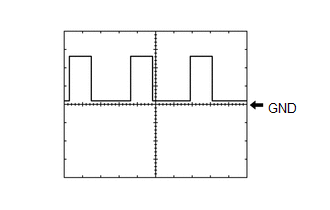

(f) Waveform 2

|

Item | Content |

|---|---|

|

Tester Connection | A169-10 (NE) - A169-6 (DGND) |

|

Tool Setting | 5 V/DIV., 2 ms./DIV. |

|

Condition | Idling after engine warmed up |

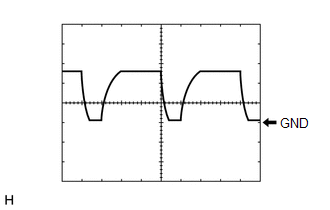

(g) Waveform 3

|

Item | Content |

|---|---|

|

Tester Connection | A169-19 (DON2) - A169-6 (DGND) |

|

Tool Setting | 5 V/DIV., 2 ms./DIV. |

|

Condition | Engine running |

(h) Waveform 4

|

Item | Content |

|---|---|

|

Tester Connection | A169-27 (NOPM) - A169-6 (DGND) |

|

Tool Setting | 5 V/DIV., 5 ms./DIV. |

|

Condition | One of the following conditions is met:

|