Toyota Corolla Cross: Terminals Of Ecu

TERMINALS OF ECU

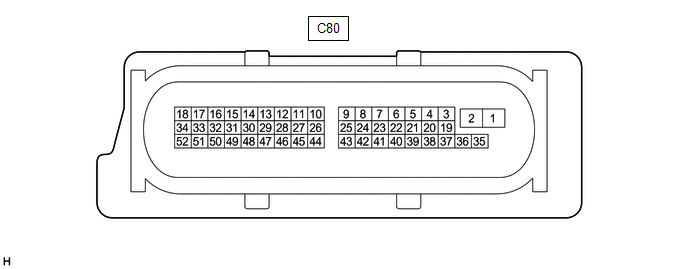

TCM

HINT:

The standard voltage and resistance between each pair of TCM terminals is shown in the table below.

The appropriate conditions for checking each pair of terminals are also indicated. The result of checks should be compared with the standard voltage or resistance for that pair of terminals shown in the "Specified Condition" column.

Use the illustration above as a reference for the TCM terminals.

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

C80-1 (+B) - C80-2 (E1) |

Power source of TCM |

Ignition switch ON |

11 to 14 V |

|

C80-2 (E1) - Body ground |

Ground |

Always |

Below 1 Ω |

|

C80-4 (SLS+) - C80-3 (SLS-) |

Shift solenoid valve SLS signal |

Engine idling |

Pulse generation |

|

C80-6 (SLU+) - C80-5 (SLU-) |

Shift solenoid valve SLU signal |

Lock-up turned from OFF to ON |

Pulse generation |

|

C80-7 (NSSO) - C80-2 (E1) |

Transmission revolution sensor (NSS) signal |

Vehicle being driven with shift lever in D |

Pulse generation |

|

C80-8 (NC1O) - C80-2 (E1) |

Transmission revolution sensor (NC1) signal |

Vehicle being driven in gear mode |

Pulse generation |

|

C80-9 (NTO) - C80-2 (E1) |

Transmission revolution sensor (NT) signal |

Vehicle being driven with shift lever in D |

Pulse generation |

|

C80-10 (NOO) - C80-2 (E1) |

Transmission revolution sensor (NOUT) signal |

Vehicle being driven with shift lever in D |

Pulse generation |

|

C80-13 (NE) - C80-2 (E1) |

Crankshaft position sensor signal from ECM |

Engine idling with warm engine |

Pulse generation |

|

C80-14 (S) - C80-2 (E1) |

M position switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-15 (CANH) - C80-2 (E1) |

CAN communication line |

Ignition switch ON |

Pulse generation |

|

C80-16 (CANL) - C80-2 (E1) |

CAN communication line |

Ignition switch ON |

Pulse generation |

|

C80-17 (CAN-) - C80-2 (E1) |

CAN communication line to ECM |

Ignition switch ON |

Pulse generation |

|

C80-18 (CAN+) - C80-2 (E1) |

CAN communication line to ECM |

Ignition switch ON |

Pulse generation |

|

C80-19 (SL2+) - C80-20 (SL2-) |

Shift solenoid valve SL2 signal |

Vehicle being driven in belt mode |

Pulse generation |

|

C80-21 (SLG+) - C80-22 (SLG-) |

Shift solenoid valve SLG signal |

|

Pulse generation |

|

C80-23 (NSSB) - C80-2 (E1) |

Power source of transmission revolution sensor (NSS) |

Ignition switch ON |

11 to 14 V |

|

C80-24 (NC1B) - C80-2 (E1) |

Power source of transmission revolution sensor (NC1) |

Ignition switch ON |

11 to 14 V |

|

C80-25 (NTB) - C80-2 (E1) |

Power source of transmission revolution sensor (NT) |

Ignition switch ON |

11 to 14 V |

|

C80-26 (NOB) - C80-2 (E1) |

Power source of transmission revolution sensor (NOUT) |

Ignition switch ON |

11 to 14 V |

|

C80-27 (SFTD) - C80-2 (E1) |

Down-shift switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-28 (SFTU) - C80-2 (E1) |

Up-shift switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-29 (P) - C80-2 (E1) |

P position switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-30 (R) - C80-2 (E1) |

R position switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-31 (D) - C80-2 (E1) |

D position switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-32 (N) - C80-2 (E1) |

N position switch signal |

|

11 to 14 V |

|

Below 1 V |

||

|

C80-38 (SL1+) - C80-37 (SL1-) |

Shift solenoid valve SL1 signal |

Vehicle being driven in gear mode |

Pulse generation |

|

C80-40 (SLP+) - C80-39 (SLP-) |

Shift solenoid valve SLP signal |

Engine idling |

Pulse generation |

|

C80-41 (IGSW) - C80-2 (E1) |

Ignition switch signal |

Ignition switch ON |

11 to 14 V |

|

C80-43 (STP) - C80-2 (E1) |

Stop light switch assembly signal |

Brake pedal depressed |

7.5 to 14 V |

|

Brake pedal released |

Below 1.5 V |

||

|

C80-45 (VCSF) - C80-44 (E2SF) |

Power source of shift stroke sensor |

Ignition switch ON |

4.5 to 5.5 V |

|

C80-46 (SFV) - C80-44 (E2SF) |

Shift stroke sensor signal |

Synchronizer engaged |

1.19 to 1.29 V |

|

Synchronizer not engaged |

3.64 to 3.74 V |

||

|

C80-49 (VCPT) - C80-48 (EPTO) |

Power source of oil pressure sensor |

Ignition switch ON |

4.5 to 5.5 V |

|

C80-50 (PTO) - C80-48 (EPTO) |

Oil pressure sensor signal |

Engine idling with shift lever in P |

0.8 to 1.2 V |

|

C80-51 (THO1) - C80-52 (ETHO) |

CVT fluid temperature sensor signal |

CVT fluid temperature: 60 to 120°C (140 to 248°F) |

0.2 to 1.0 V |

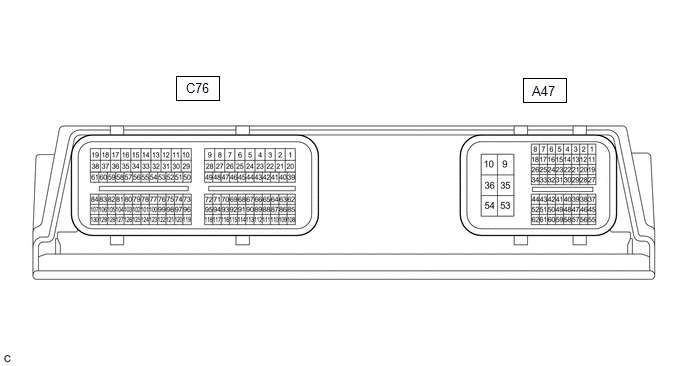

ECM

HINT:

The standard voltage and resistance between each pair of ECM terminals is shown in the table below.

The appropriate conditions for checking each pair of terminals are also indicated. The result of checks should be compared with the standard voltage or resistance for that pair of terminals shown in the "Specified Condition" column.

Use the illustration above as a reference for the ECM terminals.

|

Terminal No. (Symbol) |

Terminal Description |

Condition |

Specified Condition |

|---|---|---|---|

|

C76-40 (CANP) - A47-10 (E1) |

CAN communication line to TCM |

Ignition switch ON |

Pulse generation |

|

A47-9 (+B) - A47-10 (E1) |

Power source of ECM |

Ignition switch ON |

11 to 14 V |

|

A47-16 (NEO) - A47-10 (E1) |

Crankshaft position sensor signal to TCM |

Engine idling with warm engine |

Pulse generation |

|

C76-39 (CANN) - A47-10 (E1) |

CAN communication line to TCM |

Ignition switch ON |

Pulse generation |

|

A47-30 (STA) - A47-10 (E1) |

Starter assembly signal |

Cranking |

6.0 V or higher |

|

A47-35 (+B2) - A47-10 (E1) |

Power source of ECM |

Ignition switch ON |

11 to 14 V |