Toyota Corolla Cross: Steering Angle Sensor Wrong Installation (X0455)

DESCRIPTION

|

Code |

Tester Display |

Measurement Item |

Trouble Area |

|---|---|---|---|

|

X0455 |

Steering Angle Sensor Wrong Installation |

History of steering sensor being installed incorrectly |

|

CAUTION / NOTICE / HINT

NOTICE:

After performing the inspection, check and clear the vehicle control history (RoB).

HINT:

When Steering Angle Sensor Wrong Installation (X0455) is stored, output control may operate, but this is not a malfunction.

PROCEDURE

|

1. |

CHECK FOR DTCs (HEALTH CHECK) |

(a) Perform the Health Check using the GTS.

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTCs are output |

B |

| B | .gif)

|

GO TO DIAGNOSTIC TROUBLE CODE CHART |

|

|

2. |

ALIGN FRONT WHEELS FACING STRAIGHT AHEAD |

|

|

3. |

READ VALUE USING GTS (STEERING ANGLE SIGNAL INFORMATION) |

(a) Check Data List item "Steering Angle Signal Information".

Chassis > Steering Angle Sensor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Steering Angle Signal Information |

Steering angle value (Rotation to the left side is positive) |

Min.: -3072.0 deg Max.: 3070.5 deg |

Turning left: 0.0 to 3070.5 deg Turning right: -3072.0 to 0.0 deg |

During steering operation: Changes in proportion with steering wheel rotation |

|

Tester Display |

|---|

|

Steering Angle Signal Information |

(b) Save the steering angle signal information to the GTS memory.

NOTICE:

- If the value is +/- 360 deg (+/-15 deg), the steering sensor was incorrectly installed by 1 rotation.

- If the value is +/- 720 deg (+/-15 deg), the steering sensor was incorrectly installed by 2 rotations.

- In situations other than the above, the steering sensor may have been

incorrectly installed by 3 or more rotations.

In this case, it is possible that the proper installation or removal procedures were not followed, and the steering sensor may have been damaged.

|

Result |

Proceed to |

|---|---|

|

0 deg (+/- 15 deg) |

A |

|

+/- 360 deg (+/-15 deg) or +/- 720 deg (+/-15 deg) |

B |

|

None of the above conditions are met |

C |

| B | .gif)

|

GO TO STEP 7 |

| C | .gif)

|

GO TO STEP 13 |

|

|

4. |

CLEAR VEHICLE CONTROL HISTORY (RoB) |

(a) Using the GTS, clear the Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

|

5. |

PERFORM ZERO POINT CALIBRATION OF STEERING SENSOR |

(a) Disconnect cable from negative (-) auxiliary battery terminal.

HINT:

If the cable is not disconnected from the negative (-) auxiliary battery terminal, it may not be possible to obtain an accurate steering sensor zero point.

(b) Connect cable to negative (-) auxiliary battery terminal.

(c) Drive the vehicle straight ahead at 35 km/h (22 mph) or more for at least 5 seconds.

|

|

6. |

CHECK VEHICLE CONTROL HISTORY (RoB) |

(a) Perform a road test under the same malfunction conditions recreated based on the Freeze Frame Data or customer problem analysis.

(b) Using the GTS, check for Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

Result |

Proceed to |

|---|---|

|

X0455 is not output |

A |

|

X0455 is output |

B |

| A | .gif)

|

END |

| B | .gif)

|

REPLACE STEERING SENSOR |

|

7. |

ADJUST SPIRAL CABLE WITH SENSOR SUB-ASSEMBLY |

(a) Remove the spiral cable with sensor sub-assembly.

Click here .gif)

NOTICE:

- Be sure to disconnect the cable from the negative (-) auxiliary battery

terminal before removing the spiral cable with sensor sub-assembly.

HINT:

If the cable is not disconnected from the negative (-) auxiliary battery terminal, it may not be possible to obtain an accurate steering sensor zero point.

- Do not disconnect the steering sensor from the spiral cable.

|

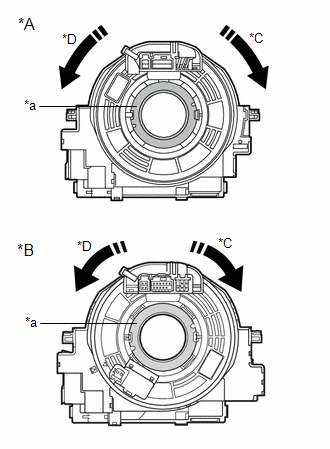

(b) Based on the internal steering angle value that was saved to the GTS memory earlier, rotate the spiral cable with sensor sub-assembly. |

|

NOTICE:

- Rotate the steering sensor without disconnecting it from the spiral cable.

- Make sure to follow the adjustment method shown in the table.

- Failure to observe the following precautions may result in damage to

the spiral cable with sensor sub-assembly.

- When rotating the spiral cable with sensor sub-assembly, make sure to push on the interlock to release the interlock.

- Do not turn the spiral cable with sensor sub-assembly using the airbag wire harness.

- Do not forcibly rotate the part.

- Make sure to perform the correct number of rotations in the correct direction.

|

Steering Angle Signal Information |

Correction Method |

|---|---|

|

360 deg (+/-15 deg) |

Rotate clockwise (to the right), 1 rotation. |

|

- 360 deg (+/-15 deg) |

Rotate counterclockwise (to the left), 1 rotation. |

|

720 deg (+/-15 deg) |

Rotate clockwise (to the right), 2 rotations. |

|

- 720 deg (+/-15 deg) |

Rotate counterclockwise (to the left), 2 rotations. |

(c) Install the spiral cable with sensor sub-assembly.

Click here .gif)

|

|

8. |

ALIGN FRONT WHEELS FACING STRAIGHT AHEAD |

|

|

9. |

READ VALUE USING GTS (STEERING ANGLE SIGNAL INFORMATION) |

(a) Check Data List item "Steering Angle Signal Information".

Chassis > Steering Angle Sensor > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Steering Angle Signal Information |

Steering angle value (Rotation to the left side is positive) |

Min.: -3072.0 deg Max.: 3070.5 deg |

Turning left: 0.0 to 3070.5 deg Turning right: -3072.0 to 0.0 deg |

During steering operation: Changes in proportion with steering wheel rotation. |

|

Tester Display |

|---|

|

Steering Angle Signal Information |

|

Result |

Proceed to |

|---|---|

|

0 deg (+/- 15 deg) |

A |

|

None of the above conditions are met |

B |

| B | .gif)

|

REPLACE STEERING SENSOR |

|

|

10. |

CLEAR VEHICLE CONTROL HISTORY (RoB) |

(a) Using the GTS, clear the Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

|

11. |

PERFORM ZERO POINT CALIBRATION OF STEERING SENSOR |

(a) Drive the vehicle straight ahead at 35 km/h (22 mph) or more for at least 5 seconds.

|

|

12. |

CHECK VEHICLE CONTROL HISTORY (RoB) |

(a) Perform a road test under the same malfunction conditions recreated based on the Freeze Frame Data or customer problem analysis.

(b) Using the GTS, check for Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

Result |

Proceed to |

|---|---|

|

X0455 is not output |

A |

|

X0455 is output |

B |

| A | .gif)

|

END |

| B | .gif)

|

REPLACE STEERING SENSOR |

|

13. |

CHECK STEERING WHEEL ASSEMBLY CENTER POSITION |

(a) Perform steering wheel assembly center position adjustment.

Click here .gif)

|

|

14. |

ADJUST WHEEL ALIGNMENT |

for front wheel alignment: Click here

.gif)

for rear wheel alignment (for 2WD): Click here

.gif)

for rear wheel alignment (for AWD): Click here

.gif)

|

|

15. |

CLEAR VEHICLE CONTROL HISTORY (RoB) |

(a) Using the GTS, clear the Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

|

16. |

PERFORM STEERING SENSOR ZERO POINT CALIBRATION |

(a) Disconnect cable from negative (-) auxiliary battery terminal.

HINT:

If the cable is not disconnected from the negative (-) auxiliary battery terminal, it may not be possible to obtain an accurate steering sensor zero point.

(b) Connect cable to negative (-) auxiliary battery terminal.

(c) Drive the vehicle straight ahead at 35 km/h (22 mph) or more for at least 5 seconds.

|

|

17. |

CHECK VEHICLE CONTROL HISTORY (RoB) |

(a) Perform a road test under the same malfunction conditions recreated based on the Freeze Frame Data or customer problem analysis.

(b) Using the GTS, check for Vehicle Control History (RoB).

Chassis > Brake/EPB > Utility|

Tester Display |

|---|

|

Vehicle Control History (RoB) |

|

Result |

Proceed to |

|---|---|

|

X0455 is not output |

A |

|

X0455 is output |

B |

| A | .gif)

|

END |

| B | .gif)

|

REPLACE STEERING SENSOR |

.gif)