Toyota Corolla Cross: Right Rear Wheel Speed Sensor Internal Electronic Failure (C051249)

DESCRIPTION

When the system is starting up and the skid control ECU (brake actuator assembly) detects a speed sensor circuit malfunction via the speed sensor circuit self-diagnosis function, this DTC is stored.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C051249 |

Right Rear Wheel Speed Sensor Internal Electronic Failure |

A circuit malfunction in the speed sensor is detected during the self test. |

|

- *1: for AWD

- *2: for 2WD

WIRING DIAGRAM

Refer to DTC C051212.

Click here .gif)

PROCEDURE

|

1. |

CHECK VEHICLE |

(a) Check the vehicle specification.

|

Result |

Proceed to |

|---|---|

|

for 2WD |

A |

|

for AWD |

B |

| B | .gif)

|

GO TO STEP 13 |

|

|

2. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

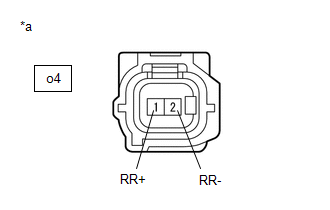

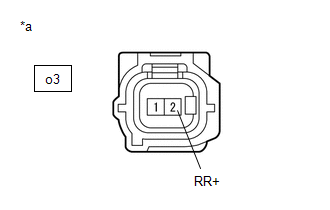

(b) Disconnect the o3 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o3-2 (RR+) - o3-1 (RR-) |

Ignition switch ON |

11 to 14 V |

| NG | .gif)

|

GO TO STEP 8 |

|

|

3. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the o3 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o3-2 (RR+) - Body ground |

Ignition switch off |

Below 1.5 V |

| NG | .gif)

|

GO TO STEP 6 |

|

|

4. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

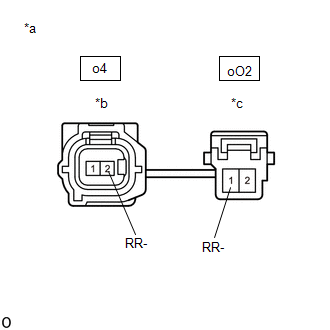

(b) Disconnect the o3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

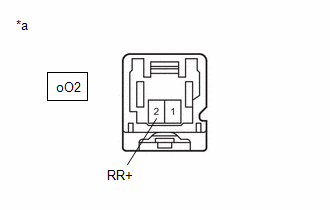

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o3-1 (RR-) or oO2-1 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

5. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR-) or A151-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE REAR AXLE HUB AND BEARING ASSEMBLY RH |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR+) - Body ground |

Ignition switch off |

Below 1.5 V |

| OK | .gif)

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

7. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR+) - Body ground |

Always |

Below 1.5 V |

| OK | .gif)

|

REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR+) - oO2-1 (RR-) |

Ignition switch ON |

11 to 14 V |

| OK | .gif)

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

9. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR+) - Body ground |

Ignition switch ON |

11 to 14 V |

| NG | .gif)

|

GO TO STEP 12 |

|

|

10. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR-) - Body ground |

Always |

Below 1.5 V |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

11. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR-) - A151-37 (RR-) |

Always |

Below 1 Ω |

|

oO2-2 (RR+) or A151-22 (RR+) - oO2-1 (RR-) or A151-37 (RR-) |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

12. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-2 (RR+) - A151-22 (RR+) |

Always |

Below 1 Ω |

|

oO2-2 (RR+) or A151-22 (RR+) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE BRAKE ACTUATOR ASSEMBLY |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

13. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

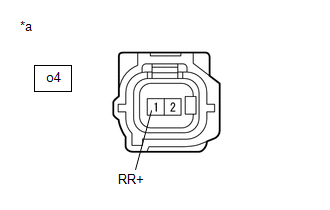

(b) Disconnect the o4 rear speed sensor RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o4-1 (RR+) - o4-2 (RR-) |

Ignition switch ON |

11 to 14 V |

| NG | .gif)

|

GO TO STEP 8 |

|

|

14. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the o4 rear speed sensor RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the ignition switch to ON.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o4-1 (RR+) - Body ground |

Ignition switch off |

Below 1.5 V |

| NG | .gif)

|

GO TO STEP 6 |

|

|

15. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the o4 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

o4-2 (RR-) or oO2-1 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

16. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A151 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the oO2 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

oO2-1 (RR-) or A151-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE REAR SPEED SENSOR RH |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)

.png)

.png)

.png)

.png)