Toyota Corolla Cross: Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the CVT fluid replacement are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effect/Inoperative Function When Necessary Procedures are not Performed |

Link |

|---|---|---|---|

|

CVT fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

|

Bleed air from oil pump (continuously variable transaxle assembly) |

Stop and start system |

|

PROCEDURE

1. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

.gif)

2. REMOVE REAR ENGINE UNDER COVER LH

Click here .gif)

.gif)

3. REPLACE CONTINUOUSLY VARIABLE TRANSAXLE FLUID

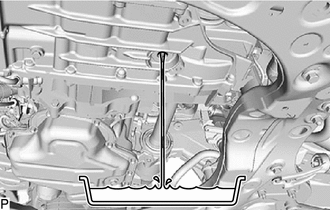

(a) Lift the vehicle. [#1]

NOTICE:

Set the vehicle on a lift so that the vehicle is kept level when it is lifted up (make sure that the tilt angle from the front to rear and side to side of the vehicle is within +/- 1°).

|

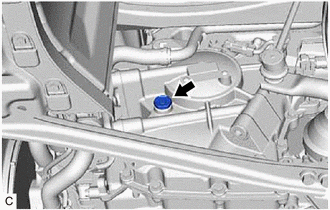

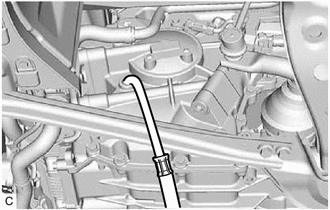

(b) Remove the refill plug and gasket from the rear transaxle case sub-assembly. [#2] |

|

|

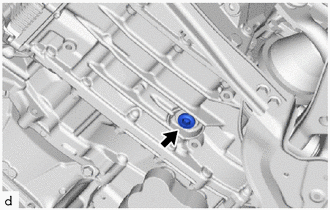

(c) Using a 10 mm hexagon socket wrench, remove the overflow plug and gasket from the transaxle case sub-assembly and drain the fluid. [#3] |

|

|

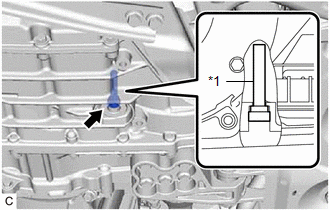

(d) Using a 6 mm hexagon socket wrench, remove the overflow (CVT) tube from the transaxle case sub-assembly and drain the fluid. [#4] |

|

|

(e) Measure the amount of fluid drained. [#5] HINT: Add the same amount of fluid in step [#8]. |

|

|

(f) Using a 6 mm hexagon socket wrench, install the overflow (CVT) tube to the transaxle case sub-assembly. [#6] Torque: 0.8 N·m {8 kgf·cm, 7 in·lbf} |

|

|

(g) Using a 10 mm hexagon socket wrench, temporarily install the overflow plug and gasket to the transaxle case sub-assembly. [#7] HINT: Reuse the old gasket as the overflow plug will be removed again to adjust the fluid level. |

|

|

(h) Add fluid to the refill hole using the same amount of fluid drained in step [#5]. [#8] NOTICE: Use Toyota Genuine CVT fluid FE. |

|

|

(i) Temporarily install the refill plug and gasket to the rear transaxle case sub-assembly. [#9] HINT: Reuse the old gasket as the refill plug will be removed again to adjust the fluid level. |

|

(j) Lower the vehicle. [#10]

(k) Start the engine. [#11]

(l) Slowly move the shift lever from P to D, and then back to P (keep the shift lever in each position for approximately 3 seconds). [#12]

HINT:

Slowly move the shift lever to circulate the fluid through each part of the continuously variable transaxle assembly.

(m) Allow the engine assembly to idle for 30 seconds to warm it up. [#13]

(n) Turn the ignition switch off. [#14]

(o) Repeat steps [#1] to [#14].

(p) Repeat steps [#1] to [#10].

4. ADD SPECIFIED AMOUNT OF FLUID

Click here .gif)

5. BLEED AIR FROM OIL PUMP ASSEMBLY

Click here .gif)

6. ADJUST FLUID TEMPERATURE (when Using the GTS)

Click here .gif)

7. ADJUST FLUID TEMPERATURE (when Not Using the GTS)

Click here .gif)

8. ADJUST FLUID LEVEL

Click here .gif)

9. PERFORM FLUID THERMAL DEGRADATION ESTIMATE RESET

NOTICE:

If approximately 50% or more of the CVT fluid has been replaced during a repair of the transaxle or a similar operation, perform ATF Thermal Degradation Estimate Reset.

Click here .gif)

.gif)

10. INSPECT FOR CONTINUOUSLY VARIABLE TRANSAXLE FLUID LEAK

(a) Make sure that there are no continuously variable transaxle fluid leaks from the area that was worked on.

11. INSTALL REAR ENGINE UNDER COVER LH

12. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)