Toyota Corolla Cross: Removal

REMOVAL

CAUTION / NOTICE / HINT

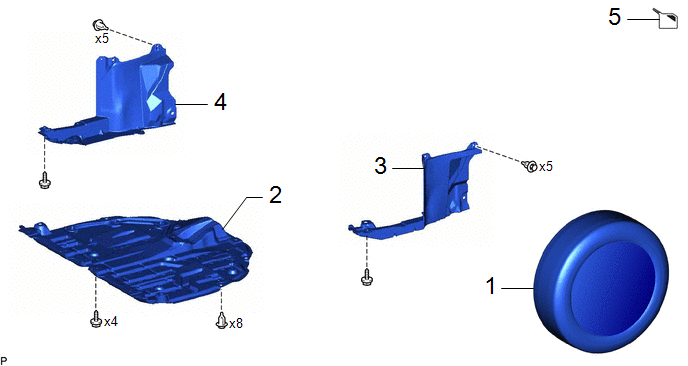

COMPONENTS (REMOVAL)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

FRONT WHEELS |

- |

- |

- |

- |

|

2 |

NO. 1 ENGINE UNDER COVER ASSEMBLY |

51410 |

- |

- |

- |

|

3 |

REAR ENGINE UNDER COVER LH |

51444A |

- |

- |

- |

|

4 |

REAR ENGINE UNDER COVER RH |

51443C |

- |

- |

- |

|

5 |

DRAIN CONTINUOUSLY VARIABLE TRANSAXLE FLUID |

- |

- |

|

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

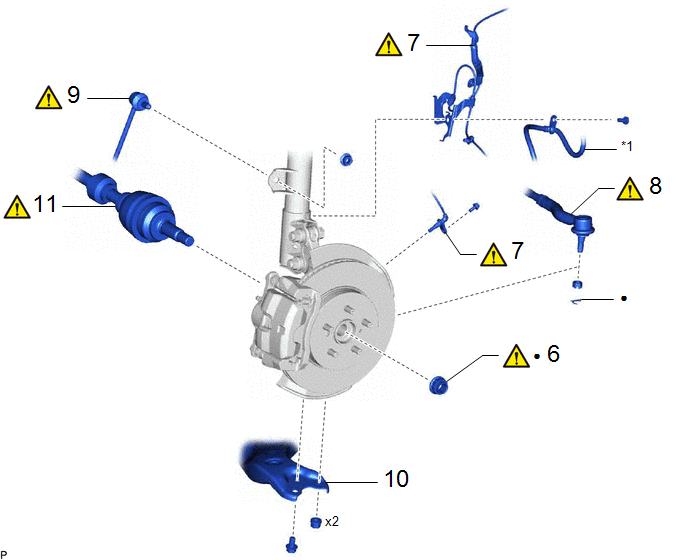

6 |

FRONT AXLE SHAFT NUT |

43502H |

|

- |

- |

|

7 |

FRONT SPEED SENSOR |

89543 |

|

- |

- |

|

8 |

TIE ROD END SUB-ASSEMBLY |

45047 |

|

- |

- |

|

9 |

FRONT STABILIZER LINK ASSEMBLY |

48810 |

|

- |

- |

|

10 |

FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY |

48069 |

- |

- |

- |

|

11 |

SEPARATE FRONT DRIVE SHAFT ASSEMBLY |

43420 |

|

- |

- |

|

*1 |

FRONT FLEXIBLE HOSE |

- |

- |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

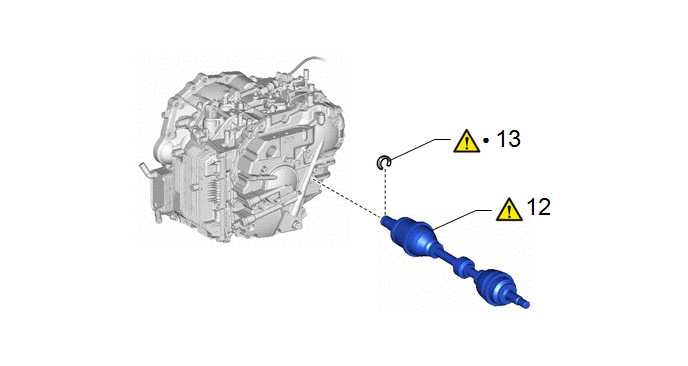

12 |

REMOVE FRONT DRIVE SHAFT ASSEMBLY |

43420 |

|

- |

- |

|

13 |

FRONT DRIVE SHAFT HOLE SNAP RING |

43420G |

|

- |

- |

|

● |

Non-reusable part |

- |

- |

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during the front drive shaft assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced|

Replacement Part or Procedure |

Necessary Procedures |

Effect/Inoperative Function When Necessary Procedures are not Performed |

Link |

|---|---|---|---|

|

CVT fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

|

Bleed air from oil pump (continuously variable transaxle assembly) |

Stop and start system |

|

|

|

Front wheel alignment adjustment |

|

|

|

|

Suspension, tires, etc. |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Initialize headlight ECU sub-assembly LH |

Automatic headlight beam level control system |

|

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

1. REMOVE FRONT WHEELS

Click here .gif)

2. REMOVE NO. 1 ENGINE UNDER COVER ASSEMBLY

Click here .gif)

3. REMOVE REAR ENGINE UNDER COVER LH

Click here .gif)

4. REMOVE REAR ENGINE UNDER COVER RH

Click here .gif)

5. DRAIN CONTINUOUSLY VARIABLE TRANSAXLE FLUID

Click here .gif)

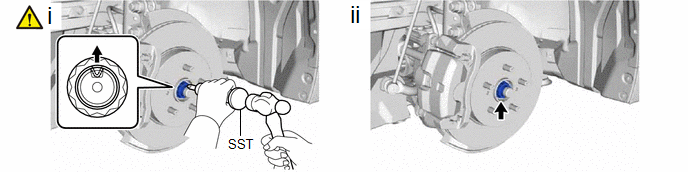

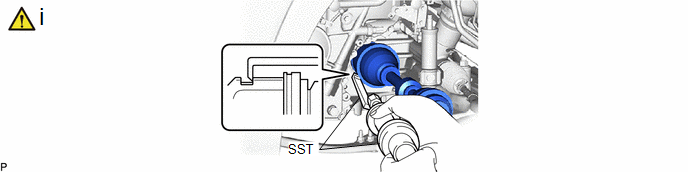

6. REMOVE FRONT AXLE SHAFT NUT

(1) Using SST and a hammer, release the staked part of the front axle shaft nut.

SST: 09930-00010

NOTICE:

Loosen the staked part of the front axle shaft nut completely, otherwise the threads of the drive shaft may be damaged.

(2) While applying the brakes, using a 30 mm deep socket wrench, remove the front axle shaft nut.

7. SEPARATE FRONT SPEED SENSOR

.png) |

Click here |

8. SEPARATE TIE ROD END SUB-ASSEMBLY

.png) |

Click here |

9. SEPARATE FRONT STABILIZER LINK ASSEMBLY

.png) |

Click here |

10. SEPARATE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY

Click here .gif)

11. SEPARATE FRONT DRIVE SHAFT ASSEMBLY

.png) |

Click here |

12. REMOVE FRONT DRIVE SHAFT ASSEMBLY

(1) Using SST, remove the front drive shaft assembly.

SST: 09520-01011

SST: 09520-20010

09521-02010

09521-02040

09521-02060

NOTICE:

- Do not damage the front drive shaft oil seal.

- Do not damage the front axle inboard joint boot.

- Do not drop the front drive shaft assembly.

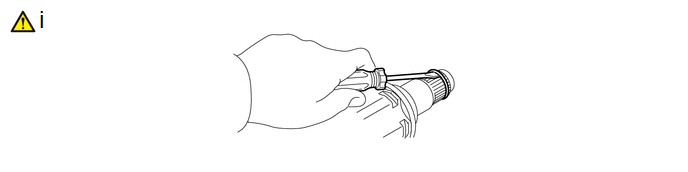

13. REMOVE FRONT DRIVE SHAFT HOLE SNAP RING

(1) Using a screwdriver, remove the front drive shaft hole snap ring.